CSC20EASAWH Hotpoint Refrigerator - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

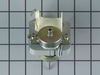

Door wouldn't stay closed & was out of alignment

This repair replaced two riser cams - one attached to the bottom fridge hinge and one attached to the bottom of the door. The two cams

mate together. So, don't just buy one cam, buy two.

1. Removed all contents off the inside of the door as well as the bins.

2. Unscrewed single screw holding plastic cover over top hinge.

3. Unscrewed 2 screws holding top hinge to the top of the door and removed the top hinge.

4. Pulled door up and off bottom hinge and layed

on floor.

5. Removed plastic grill on bottom of fridge.

6. Removed 2 screws holding bottom hinge in place.

7. Using a vice to hold the hinge, I used a hacksw to cut through the rivet holding the riser cam to the hinge plate.

8. Used a small bolt & nut to secure the new riser cam to the hinge plate.

9. Reattached hinge plate to the bottom of the fridge.

10. On bottom of the door remove two screws holding riser cam to door.

11. Position new riser cam in place and reattach to bottom of door.

NOTE: on my door, the metal SHIM that goes between the cam riser & door was also broken. I ordered the replacement SHIM but it turned out to be made of PAPER. So, I didn't bother putting it on. If the riser cam wears out again, I'll just replace it again.

12. Put door back on and secure the top hinge to the top of the fridge and you're done.

mate together. So, don't just buy one cam, buy two.

1. Removed all contents off the inside of the door as well as the bins.

2. Unscrewed single screw holding plastic cover over top hinge.

3. Unscrewed 2 screws holding top hinge to the top of the door and removed the top hinge.

4. Pulled door up and off bottom hinge and layed

on floor.

5. Removed plastic grill on bottom of fridge.

6. Removed 2 screws holding bottom hinge in place.

7. Using a vice to hold the hinge, I used a hacksw to cut through the rivet holding the riser cam to the hinge plate.

8. Used a small bolt & nut to secure the new riser cam to the hinge plate.

9. Reattached hinge plate to the bottom of the fridge.

10. On bottom of the door remove two screws holding riser cam to door.

11. Position new riser cam in place and reattach to bottom of door.

NOTE: on my door, the metal SHIM that goes between the cam riser & door was also broken. I ordered the replacement SHIM but it turned out to be made of PAPER. So, I didn't bother putting it on. If the riser cam wears out again, I'll just replace it again.

12. Put door back on and secure the top hinge to the top of the fridge and you're done.

Parts Used:

-

Rod from Nashville, TN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set, Wrench set

8 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

stopped making ice

First I turned off the water supply. Then I removed the ice bin and the ice maker by removing 4 screws and 3 electrical connections. This allowed access to the evaporator fan which was not moving. To remove the evap fan I removed two screws that hold the fan bracket. The fan assembly now had to be pushed back and rotated to remove from hole. There are 3 electrical connections that have to be disconnected from the fan, one ground wire that also is connected to the fan bracket and 2 power connections. Installing the new fan was the reverse of the above except the power connections were in a different location and i had to use the extension wires provided with the new fan to have the length needed to make the connection.

Parts Used:

-

Timothy from Orange Park, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

7 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Freezer hinge was worn

Shut off water and disconnected at factory joint at bottom hinge. Unplugged the electrical at the top hinge. Removed the door and installed new bottom hinge and cam assembly. Reinstalled the door and hooked water and electric back up. Part worked fine.

Parts Used:

-

Wilbur from Waynesboro, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Wrench (Adjustable)

6 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Refrigerator would begin to lose it's cool and we saw ice caking on the bacjk panel of the freezer section.

We had to empty the freezing section, remove the 4 screws that held the back panel and defrost the coils. Then with the diagram we got from the internet, we removed the defroster and easily installed the new one and put the back panel back on. We did find later that it was still icing over so I ordered the thermostat and we installed it today.

It too was easy to install. We spliced the wires and hooked the new thermostat to the old wires and reinstalled the back panel. Hopefully this will solve the problem for us now.

It too was easy to install. We spliced the wires and hooked the new thermostat to the old wires and reinstalled the back panel. Hopefully this will solve the problem for us now.

Parts Used:

-

Charles from Edison, GA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

7 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cams on Hinge assembly broken, door didn't close properly

I supported door with 2* 6 scrap wood. I used cedar shingles to raise door to correct height.

Using a socket wrench, I removed the hinge from the fridge and the cam assembly from the door.

I installed the new hinge and cam using the shims thatwere behind the original parts.

I removed the 2*6 supports and the door now works perfectly.

Using a socket wrench, I removed the hinge from the fridge and the cam assembly from the door.

I installed the new hinge and cam using the shims thatwere behind the original parts.

I removed the 2*6 supports and the door now works perfectly.

Parts Used:

-

Stephen from Lafayette, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

7 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken fan blade in the freezer compartment

Unplugged frige, removed top shelf, pulled broken fan blade off. Replaced with fan blade just purchased from PartSelect. Very simple repair. Orderd and recieved the right part.

Parts Used:

-

John from Cumberland, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

7 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Refrigerator would not defrost

When it was discovered there was a cooling problem in the refrigerator, I went to parts select web site and went through the troubleshooting section. Then I tested the defrost timer and the defrost element as directed by the web site. I then found out doing this, that is was the defrost timer. I ordered the part online and it was delivered THE NEXT DAY! I removed the bottom panel of the fridge, removed the screw holding the old timer, removed the wires, and reversed the procedure to install the new one. It has been 1 week, and everything is working great. Thank you PartSelect.

I have since then recommended you to a relative who was having the same problem. Thanks again.

I have since then recommended you to a relative who was having the same problem. Thanks again.

Parts Used:

-

Thomas from Dresden, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Frezer frozenin ,no icemaker working

Lets start with the hard part:

Convince wife to get a couple of her girl friends

to go to a movie and see the Reader,after that

visit a cafe or pub (remembered years ago the

English Patient). Drove to get a six pack,removed the back panel-2 min, set a hair drier to position,

had a couple beers , removed the defrost heater unit

1 min. replaced it 1 min. back panel1 min,enjoyed the rest of the afternoon,finished the beer

Killed two birds with one stone

Zoltan L Petho

Convince wife to get a couple of her girl friends

to go to a movie and see the Reader,after that

visit a cafe or pub (remembered years ago the

English Patient). Drove to get a six pack,removed the back panel-2 min, set a hair drier to position,

had a couple beers , removed the defrost heater unit

1 min. replaced it 1 min. back panel1 min,enjoyed the rest of the afternoon,finished the beer

Killed two birds with one stone

Zoltan L Petho

Parts Used:

-

zoltan from New York, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Refridgerator quit cooling because the defrost element had burned out and the refridgerator coils were totally covered with ice.

I defrosted freezer. Removed cover from back of freezer. Removed screws from element disconected wires. I connected wires to new element installed screws and reinstalled cover.

Parts Used:

-

sherry from runaway bay, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

6 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

excessive door swing

Removed the top hinge and the door.

Removed door stop held in place by 2 screws, installed new door stop.

re-installed door and top hinge.

Easy once the correct diagnosis was made

It would have been nice if I could have e-mailed you the symptoms and received an accurate diagnosis. As it developed, I initially replaced the door cam before realizing that the door stop itself had broken.

Removed door stop held in place by 2 screws, installed new door stop.

re-installed door and top hinge.

Easy once the correct diagnosis was made

It would have been nice if I could have e-mailed you the symptoms and received an accurate diagnosis. As it developed, I initially replaced the door cam before realizing that the door stop itself had broken.

Parts Used:

-

PETER from ENGLEWOOD, NJ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench (Adjustable)

6 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Freezer kept freezing up

Removed the cover for the evaporater coils and let them defrost. Then took the old heating element out by removing two screws on the bottom element and two screws on the top element. Unplugged it and removed it from the unit. Then repeated the reverse of the procedure, installing the new unit, no wires to splice only one plug and four screws.

Parts Used:

-

Wesley from Hattiesburg, MS

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

6 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Fresh Food section door made a click noise on closing

Since the cam riser was obviously broken I obtained a replacement.

It also broke. The door hinge cam needed to be replaced also.

To repair Remove the hinge cover using a #2 phillips driver. Than remove the Hinge using an 8mm socket. Turn the door upside down and, using an 8mm socket remoge the cam riser and the door hinge cam.

Replace in reverse order.

Be sure to inspect all parts and order all required.

It also broke. The door hinge cam needed to be replaced also.

To repair Remove the hinge cover using a #2 phillips driver. Than remove the Hinge using an 8mm socket. Turn the door upside down and, using an 8mm socket remoge the cam riser and the door hinge cam.

Replace in reverse order.

Be sure to inspect all parts and order all required.

Parts Used:

-

Charles from Renton, WA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

door wouldn't close

First I propped up the door. Then I removed the 2 screws that hold the hinge on. AT this point you do need someone else because the door swings loose. I attached the new bracket and lowered the door. It went verey smooth. I ordered the new bracket after reading the installation stories from others who just repaced the plastic pieces. Its worth the extra money to just put on a new bracket

Parts Used:

-

Linda from Manorville, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door stop weakened and cracked

Two nuts, door was off. 2 nuts stop was off. Nuts on, door on, nuts on.

Could not have been more easy.

Could not have been more easy.

Parts Used:

-

James from Annapolis, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Refrigerat

rerfrigator side not cooling After determinating that the defrost timer was running I turned it to defrost and watched tosee if frost started to melt. When it didn't I checked the heater with ohmeter, checked OK, so the only other component in the defrost system is the thermostat. Then just a matter of cutting and splicing wires and snapping the new thermost in place

Parts Used:

-

Charles from Rose Bud, AR

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench set

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!