AWM393W Amana Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Seal on water pump was leaking

Unplug the washer to prevent shock while handling motor. Remove the front botton access panel. Move the drive belt off the idler pulley to provide slack to move belt off the other pulleys. Note position or take picture of belt position before removal to aid in getting it in the correct position for reinstallation. Move the hose clamps up the hoses far enough to remove the hoses from the pump. A towel is handy here as there is still a little water in the hoses and pump. Remove the four bolts holding the motor bracket to the bottom of the washer. The wiring to the motor does not need to be disconnected. Rotate the bracket with motor and pump attached so that the assembly is horizontal and the pump is to the right hand side. Use the torx bit to remove the bolts holding the pump in place. Install the new pump, being careful to get the drive belt in the proper position while doing so. Do not over tighten the bolts on the new pump since it is plastic. Rotate the motor bracket back to its original position and install the four bolts. Get all four bolts installed loosely before tightening any fully to insure the bracket is aligned properly and none of the bolts will be in a bind. Once the bolts are tight, put the drive belt on the small pulley and then work in around to position on the large pulley. Position the belt back into its position on the idler pulley. Put the hoses on the pump as far as they will go then slide the hose clamps back into their original position. Replace the bottom access panel and plug the washer back in.

Parts Used:

-

Douglas from Spring, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Socket set

10 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking pump, torn belt, washer 24 yrs old

Please read the comments from other people before you start the repair. The hints are great, and save you time.

Removing the old pump from the shaft with two screwdrivers

by gently prying it off the shaft was the best idea. Once the pump is removed from the motor, it is a snap to replace the belt, and tension pulley if necessary.

The metal surfaces are sharp inside the machine, and I suggest placing a good light inside the machine so that you can see where the belt goes. Follow Joseph's instructions from Goldsboro NC to a tee, and your repair will be a great experience.

Peter

Westport, Ma

Removing the old pump from the shaft with two screwdrivers

by gently prying it off the shaft was the best idea. Once the pump is removed from the motor, it is a snap to replace the belt, and tension pulley if necessary.

The metal surfaces are sharp inside the machine, and I suggest placing a good light inside the machine so that you can see where the belt goes. Follow Joseph's instructions from Goldsboro NC to a tee, and your repair will be a great experience.

Peter

Westport, Ma

Parts Used:

-

Peter from Westport, MA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

10 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Weak cold water flow

First I thought hoses could have been clog, turned out that the flow valve was bad

One screw to take off the value holder itself, removed the two hoses that bring hot and cold water to the valve, removed the water line that brings the cold and hot water to the washer (nothing more than a hose clamp) Was then able to remove the valve holder. Simply unbolted the value from the holder, replaced with new valve and reversed processed to re-install.

Pretty easy, about minutes

One screw to take off the value holder itself, removed the two hoses that bring hot and cold water to the valve, removed the water line that brings the cold and hot water to the washer (nothing more than a hose clamp) Was then able to remove the valve holder. Simply unbolted the value from the holder, replaced with new valve and reversed processed to re-install.

Pretty easy, about minutes

Parts Used:

-

Nicholas from Parrish, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench (Adjustable)

11 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water Inlet Valve Damaged

The Speed Queen people were nice enough to provide a swing out door on the back of the machine to access the mixing valve. I had to pry it open because they did not supply enough slack in the hose that attaches to the mixing valve. The hose clamp securing the outlet hose to the valve was difficult to remove as the screw was positioned by someone that assembled the machine with no thought given to if it would ever to be taken apart.

Be sure to unplug the machine before attempting this repair. I unplugged the dryer instead and was greeted with a shower of sparks as I removed the valve. Luckily there was no damage to me or the machine. I needed some lubricant to slide the hose onto the new valve. There was some Linatone oil for my dog's coat handy. It did the trick I buttoned the machine back up and it works as good as the day I bought it.

It might be wise to replace the gaskets between the water hoses and the inlet valve. They are just standard garden hose gaskets. Replacing the strainers on the faucet side might be a good idea also. I took a video of the Speed Queen in action and will post it to You Tube. "They Don't Make 'em Like This Anymore"

Be sure to unplug the machine before attempting this repair. I unplugged the dryer instead and was greeted with a shower of sparks as I removed the valve. Luckily there was no damage to me or the machine. I needed some lubricant to slide the hose onto the new valve. There was some Linatone oil for my dog's coat handy. It did the trick I buttoned the machine back up and it works as good as the day I bought it.

It might be wise to replace the gaskets between the water hoses and the inlet valve. They are just standard garden hose gaskets. Replacing the strainers on the faucet side might be a good idea also. I took a video of the Speed Queen in action and will post it to You Tube. "They Don't Make 'em Like This Anymore"

Parts Used:

-

Ronald from Arcadia, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench (Adjustable)

9 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wouldn't agitate or spin.

This was my fist time attempting to fix a washer. I had to guess on the length of the belt since the model number on the machine had worn off and the belt had snapped in a way that made determining the length difficult. At first, I ordered a belt that was too small. I realized this after I was unable to remount the motor stand onto the bottom of the machine. This model had the motor assembly right in front of the unit. It was easily accessed after removing the panel on the front of the machine. It was easy to remove the 4 screws (they were all visible) on the motor stand. After that I was able to disconnect the pump belt. This machine has seperate belts for agitation and the pump. The pump belt must be removed in order to install the agitator belt because they both are driven by the same shaft and the pump belt is positioned on the bottom. There is also a tension wheel for the agitator belt which might be easily overlooked. Make sure to install the agitator belt so that the tension wheel is on the outside of the belt's path. The whole job is fairly easy if you have the right part to begin with. If you have to force the belt onto the wheels, then you probably have a belt that is too small.

Parts Used:

-

Eric from Akron, OH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

9 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

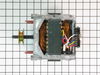

motor would't work

first i removed the 4 screws that hold the motor in place.pull the motor out and disconnected the wires ,remove the belt from the pulley, when motor was out the work was very easy 3 more bolts that hold another element in place and the rest was piece of cake ...done thanks to parts select for send me the right part at first time i recomended and i received my motor in just 3 days.congratulation

Parts Used:

-

CARLOS from MIAMI, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

12 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The thin walled plastic drain line got a pin hole leak

The washer is four years old.

This is the second time I needed to replace this same drain hose on this same washer since I had the machine

There is only my wife ant myself maybe, 2 -3 medium size loads per week - why I would have two drain lines develop the same problem in almost the same location in two years is disconcerting

There must be a design problem with the clear plastic hose - Suggest Maytag go to a thick walled rubber hose

The hole is alway inside the washer on the bottom just after the hose bracket - I suspect that something rubbing causing a small pin hole to develop - when the condition first starts it is very difficult to located -There will be water under the washer

Run the washer and discharge the water - to locate

The replacement must be made through the lower front removable panel - and is easier to do if the pump return hose is also disconnected from the pump

Be very carful with the thin wall replacement hose - very light weight plastic - do not pull across the floor of washer - it could easily get damaged

Your company did a get job getting the part to me - The Fed Ex track system was great

I could tell exactly where the delivery was al all times -

This is the second time I needed to replace this same drain hose on this same washer since I had the machine

There is only my wife ant myself maybe, 2 -3 medium size loads per week - why I would have two drain lines develop the same problem in almost the same location in two years is disconcerting

There must be a design problem with the clear plastic hose - Suggest Maytag go to a thick walled rubber hose

The hole is alway inside the washer on the bottom just after the hose bracket - I suspect that something rubbing causing a small pin hole to develop - when the condition first starts it is very difficult to located -There will be water under the washer

Run the washer and discharge the water - to locate

The replacement must be made through the lower front removable panel - and is easier to do if the pump return hose is also disconnected from the pump

Be very carful with the thin wall replacement hose - very light weight plastic - do not pull across the floor of washer - it could easily get damaged

Your company did a get job getting the part to me - The Fed Ex track system was great

I could tell exactly where the delivery was al all times -

Parts Used:

-

WALTER from Holualoa, Hawaii, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Wrench set

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Would not empty water

I suggest if you are replacing the pump, order the belt at the same time, you must remove the pump to replace the belt.

Parts Used:

-

James from Houma, LA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

8 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would not stay in balance during spin cycle

I replaced the 7 springs holding the tub in place. To do this you have to take the two front bolts out the holds to front panel on the machine. Remove the front panel and you will see the bolt in each front corner holding the top in place. Remove these. Then remove the 8 bolts at the bottom of the three remaining sides of the machine. After removing these you can move the sides out of the way enough to remove each one of the 7 springs holding the tub in place. Then one by one replace the springs and put the sides back on in the order they were removed. Hopefully, if you are having trouble keeping your machine in balance in the spin cycle, this will fix your machine as it fixed ours.

Parts Used:

-

Darrell from Midwest City, OK

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

8 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water leaking when water level is set above medium. Wash tub spinning when during agitation cycle.

Three brake pads are located just above the drive pulley and space symmetrically around the brake wheel. Remove the one screw per brake, slide brake out of brake wheel and replace with new brake. Apply silicone grease to new brakes before installing. Tools: 5/16 boxed end wrench.

Parts Used:

-

Martin from Grayslake, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Wrench set

7 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer leaking water from the bottom.

Removed front panel.

Released 2 springs on belt tensioner.

Rolled drive belt off pulleys.

Unscrewed 4 bolts holding washer motor assembly.

Tilted motor to get at pump screws.

Removed 3 pump screws and pump slid right off shaft.

Aligned new pump and reinstalled screws.

Set motor assembly loosely in place.

Rolled drive belt onto pulleys.

Re-attached tension springs.

Installed motor assembly bolts.

Re-installed front panel.

** I should have replaced drive belt at same time, but it is working with no leaks.

Released 2 springs on belt tensioner.

Rolled drive belt off pulleys.

Unscrewed 4 bolts holding washer motor assembly.

Tilted motor to get at pump screws.

Removed 3 pump screws and pump slid right off shaft.

Aligned new pump and reinstalled screws.

Set motor assembly loosely in place.

Rolled drive belt onto pulleys.

Re-attached tension springs.

Installed motor assembly bolts.

Re-installed front panel.

** I should have replaced drive belt at same time, but it is working with no leaks.

Parts Used:

-

Donald from Sierra Vista, AZ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Socket set

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

replace rubber drain hose adapter

Place black rubber adapter on the end of the drain hose and stick in the stand pipe drain. That's all.

Parts Used:

-

Frank from Austin, TX

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking water while washer runs

Biggest trick is getting the agitator off. It seems like it is bolted on. I used a piece of braided cotton cord to run under both sides of the agitator and just pulled real hard. It WILL pop off.

Next the old seal will also seem to be attached. The edge is firm but not bolted. A small prybar will help.

Easy repair to do, but it did not fix my problem. I decided to get a new washer rather than go through further disassembly.

Next the old seal will also seem to be attached. The edge is firm but not bolted. A small prybar will help.

Easy repair to do, but it did not fix my problem. I decided to get a new washer rather than go through further disassembly.

Parts Used:

-

John from Roswell, GA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

10 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

pump seal leaked; retaining ring sprung

pull front cover off of machine, disconnect motor wiring harness. Remove 4 sheet metal screws holding motor / pump assembly to frame. Remove both pump hoses (caution - have towels and a bucket at the ready). Pull unit from machine. turn upside down on bench and replace components. Reverse for installation.

Parts Used:

-

Richard from Soldotna, AK

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

leaking from pump

removed hoses from pump, removed 4 screws holding motor housing to washer, disconnected wiring from motor. It will make your life easier to re-assemble if you pay attention to how belt is located in relation to the legs of the pump. pump came off motor very easily. I had the old pump out and the new pump in and working in about 30 minutes.

Parts Used:

-

James from Montgomery, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

6 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!