ALG643RMC1 (PALG643RMC1) Amana Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Dryer wouldn't tumble

I consulted the instructional video before starting to take the dryer apart. My model is older than the one used in the video but it was still very helpful. Putting the belt on was fairly easy; however, I didn't know I also needed a rear drum wheel as well so while the belt is installed, the dryer still doesn't tumble when anything is in it. Off balance without 2nd rear drum wheel.

Parts Used:

-

Glenda from Walters, OK

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Idler pulley was sticking on shaft, causing a squeaking sound

removed front panels, open the top of dryer. Removed the three screws holding blower panels and removed them. Then removed belt, drum and replaced the pulley. In reverse order reinstalled the parts. Done all is quit and no more squeak.

Parts Used:

-

Erwin from Somersworth, NH

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

The lint filter had broken

I opened the package that arrived and inserted the new lint filter into the place where the old one was. Then I threw the old lint filter away

Parts Used:

-

Charlene from Presque Isle, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

Loud squeaking during operation

The video on this site for replacing the drum support roller was quite good but for my particular model of dryer was not totally applicable. The video shows that by using a putty knife to disengage two spring clips in front, the top would open but my dryer had two screws in addition to the spring clips securing the top down. Those screws were accessed after taking off the front of the dryer first. That cost a little bit of time as it was an unexpected step and I did not want to damage my dryer. If your top cover is not popping off as easily as in the video, look for two screws on each corner holding it down. Other than that variation, the rest of the repair went as shown in the video. I did not isolate the cause of the squeaking to a drum support roller, the idler pulley wheel, or the belt but I decided to change out all of them since I would have the dryer apart and the parts are not expensive. I would recommend not buying the overpriced thrust washer and retaining ring as the old ones can be reused if you have removed the ring carefully with ring clip pliers. Notes about the repair: It is easy and I was able to do it without help with the drum. Take the time to do a good vacuum while you're in there. You can get an inexpensive set of ring clip pliers from Harbor Freight. They really helped and even a set of small needle nose pliers would not have been useful. Note about Parts Select: The prices for the parts was reasonable, with the exception of the thrust washer and retaining ring. Shipping was very fast and my order was fulfilled perfectly. I will return.

Parts Used:

-

Kevin from Indio, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

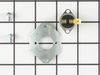

Dryer would stat but no heat

The part came in very quickly. If you know how to remove the front panel, it is very easy to repair. The hard part is to diagnose the problem. The first thing to check is the igniter. If it comes on then you look for faulty limit switches. If you have lots of training in electronics and appliance repair this is very easy, if you do not I would not try this. I have 40 years in the repair business, It still took me 1hr. to find the problem. the switch was intermitted, one time the dryer would work the next time it would not. Good luck and happy repairs.

Parts Used:

-

Quinn from Los Alamos, NM

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

The door would not shut

-

Deborah from Worcester, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

No Power

Installing the new switch was a snap. With the dryer unplugged, open the top using a putty knife to release the 2 clips - one on each side. Lift the top and support it to stay open. Next, note the wire color and location for each of the 3 wires. Remove each wire from its prong on the bad switch by gripping the connector with pliers and pulling off. Next remove the bad switch by squeezing the tabs on the sides of the switch to release it. The switch removes to the front of the dryer. Install the new switch in the same method and reconnect the wires as before making sure the colors go back on the same prongs. I had to replace one of the connectors with a larger one (that came with the switch) since one of the prongs on the new switch was larger than the orginal (bad) switch. To do this, I cut the old connector off, stripped the end of the wire, and crimpted on the new connector. I had to be careful not to waste too much wire since there was very little slack to work with.

Parts Used:

-

John from Bel Air, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

Was this instruction helpful to you?

Thank you for voting!

loud squeaking

I unplugged the dryer, pushed the clips loose and tipped the lid up and tied it open to a cabinet above. Disconnected the electrical connections to the front panel and removed front panel. Then I disconnected the electrical connections to the drum support. Removed four sheet metal screws holding the support and lifted out the support. Removed the drum glides at the bottom, installed the new drum glides with felt pads. I replaced the drum rollers just so I didn't have to do it later. Put everything back in reverse order and running quiet! Well worth the $42.57 spent for parts and postage.

Parts Used:

-

Harvey L from Pine Ridge, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

High pitched squeaking upon startup

Besides successfully ordering the correct part I also noticed there were instructions on the website as to it's removal process. MOST helpful, I had not predicted the difficulty in doing it until I read the instructions. Very helpful.

Parts Used:

-

Paul from San Antonio, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

Was this instruction helpful to you?

Thank you for voting!

Clothes were not getting dry enought

Unplugged dryer from power source, used putty knife to release latches that hold top on, tilted the top out of the way, unplugged door lite, located the radiant switch, removed 1 screw,then undid 2 wires & lifted out switch. Reversed procedure plugged in dryer....wa la had dried a large load of clothes, took 1/3 the time to dry clothes at last. Thanks "PartSelect"

Parts Used:

-

Michael from Royal Palm Beach, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

dryer roller wheels

-

Kenneth E from Almont, MI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers

Was this instruction helpful to you?

Thank you for voting!

Duct fan separated

First time through it was an interesting adventure... Had to take the front completely apart... When I took the drum out that is when a roller earning had melted off... And the limit timer was broken... The second time through it went faster... And I had my son help... He is not mechanically inclined but he did well...

Parts Used:

-

Kelley from Eureka, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Correct noise problem

Remove drum assembly, replace drum roller, belt with Pulley wheel bearing. The whole problem was corrected and the unit now runs like new.

Parts Used:

-

Angelo Barreto from Flowery Branch, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Door Latch broken

-

Eugene from Arlington, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Very noisy, stopped during cycle, would restart after a while but was getting worse.

I removed the front panels, lint screen, ductwork to fan, motor assembly, drum, drum rollers, and vent pipe to outside. I then cleaned years of accumulated lint and dust from the cabinet. Replaced the drum rollers, drum glide, idle pulley and motor assembly. The hardest part was getting my arm in to place the idle pulley onto the drive belt.

Parts Used:

-

Michael from Hill City, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!