ALG643RBW Amana Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

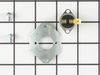

hi temp therm unit

Well I first attemptede the repair wthout following the online instuction's, I dont recomend it.After some 30 minutes wasted trying to fit my hands in and droping the screw a couple of times, I decided it was time to remove the duct that supplies the air thru the lint trap, after that the repair was a breeze

Parts Used:

-

John from West Milford, NJ

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

would not heat

changed fuse,radiant flame sensor. no help. bought a new dryer. i don't think the gas valuve was opening.everything seemed to be working properly,just no gas.

Parts Used:

-

marc from bristol, WI

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!

The ignitor would lite, but no gas from the valve, then ignitor would shut off

It was a fairly simple repair to perform with the dryer in place. I simply opened the bottom/front access panel to start, the door removes if you pull up after opening. Then I disconnected the two and three wire connector to the two coils. Next I removed the bracket screws that fasten the coils to the valve assembly. This was a little difficult with the screw closest, because of the small clearance and #1 sized phillips(stubby would work well.) The rear screw I managed to remove by using both a small flathead screwdriver(hex shaped shaft) and an adjustable cresent wrench. At this point, it was a simple matter of installing the new coils and the bracket, and then reconnecting the two plugs. It almost made me want to do laundry.

Parts Used:

-

Lee from Madisonville, KY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!

Loud squealing sound on startup goes away when warmed up

Pretty much followed the instructions on the video on the website, very helpful! My model takes 2 rollers, and 2the glides, it wasn't obvious when I ordered the parts that I needed 2 of them. However I installed 1 new roller and 1 new Glide as well as the new belt and the tensioner pulley. Definitely take time to clean out the inside of the dryer it will be very dirty if you have never cleaned it before. Also remember to grease any new rollers. dryer was quiet and ran perfectly after this install.

Parts Used:

-

Kevin from Parker, CO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

It woud begin to heat and dry clothes then it would stop heating before the clothe dried.

Parts Select said 27% chance it was the coils and 26% chance it was moisture sensor. I ordered the coils and it did not fix the problem, my luck. I have now ordered moisture sensor and the next possible part, the cycling thermostat. If one of these solve the problem I will still have much less invested than a repairman would charge.

Parts Used:

-

Thomas from Bath, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Load Screeching Noise

Removed panels and kept screws together. Removed Multi-Rib Belt and carefully lifted tumbler out. This exposed idler pulley wheel and drum support roller. Removed and replaced New Idler pulley wheel and New drum support roller. Carefully inserted Tumbler and installed New Multi Rib Belt. Manually turned tumbler a couple of times to confirm tension. Pluged in for test and wallop! Purrrs like a kitten.

Parts Used:

-

Maria from Commerce, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Dryer would heat up at startup but not stay hot for long. Took forever to dry clothes. Started smelling a very slight gas leak about a week before the problem started. I suspect the coils have been going lame for quite some time. The dryer heats up like it was new.

Downloaded a schematic of the dryer controls. Watched a UTUBE video of how to remove the front panel of a Maytag Performa dryer. It was pretty easy. Consulted your website and found out that bad coils are typical of the symptoms 46% of the time. I have bought parts from you before and happy with results.

Parts Used:

-

dan from Orinda, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

The iddler pulley was squeeling real loud

I removed the toe panel,removed bottom screws from front main panel,removed vent housing,removed main front[outer],removed the screws from top[each side,front],raise top up[hook string to coner of top and tieded it up],removed front panel[4 screws]"front of tub runs on",undo old belt from iddler pulley,removed drum and old belt,removed 2 screws that holds motor assy and removed motor assy,replaced old iddler and pulley,relaced drum glides with new ones,replace tub rollers.Reinstall motor assy, tub, belt, fronts,ck out sound like a new dryer. While I was fixing the iddler pulley I replace all main parts,never was change sence new. Sence I was a retired tec from SEARS and age 74 it was tiring for me,wouldn't been if I was younger.....

Parts Used:

-

Charles from Farmington, MN

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

the motor quit working

i took the front off the dryer took belt loose took the tub out the plastic nut on the blower wheel striped out so i took the blower housing apart along with the motor got vise grips on blower wheel replaced motor blower wheel belt and belt tenchinor and spring cleaned all the lint put it back together works fine

Parts Used:

-

betty from huffman, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!

broken door catch: female half

noticed that male half was in good working order, so I just snapped in the new female half; without any tools. easy repair!

Parts Used:

-

Allen from Seattle, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

flame out

-

john from glen head, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Inadequat Heat, Too Much Lint Flying

Ordered new lint filter from part select; paid for it with credit card on line; waited for delivery in one week; received by ups; unboxed; cleaned filter trap area with vacume; and dropped in new filter.

Parts Used:

-

LEONARD from Rolling Hills Estates, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

Dryer worked but did not heat

Followed troubleshooting steps. Checked thermal fuse (shorted)- OK. Checked igniter (about 70 ohms) - OK. checked flame sensor - (open) BAD (should read shorted). This part is normally shorted then opens when the igniter gets hot causing it to open and thus turns on the gas flow. An open flame sensor does not permit the igniter to turn on.

Parts Used:

-

Steven from Garden City, NY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Squealing when running

I had already taken the dryer apart prior to changing the felt seal. Had oiled the rollers, greased the bearings & vacuumed the whole inside of the dryer out. Had used a high temp lubricant on the seal & had stopped squeaking for about a month. I ordered 2 seals & when they arrived, I popped the top of the dryer off using the putty knife to pry the spring latches. I opened the top up & leaned it against a wall. I disconnected the wiring to the light & the switch in the door, making note of the wiring order. Then used a nut driver to take the 2 screws from the inside out, that holds the front cover in place. Then the same for the 4 screws holding the front bulkhead in place. Then lifted up & out from the unit. Then used the putty knife to scrap the adhesive & old seal off the bulkhead. Cleaned as much of the adhesive off, then applied some high temp silicone adhesive to the bulkhead, placed the new seal on, using some clamps to hold it in place. After making sure it had adhered to the seal & bulkhead. Did the reversal of the above mentioned steps. Moved the unit to laundry room, plugged it in then started it & voila no more squeaking dryer.

Parts Used:

-

Eric from Carlsbad, NM

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

needed new dryer belt

The repair went better than expected. I watched the video of how to replace the dryer belt and although it wasn't exactly the same, just by watching the video I was able to find my way through the process. Thank you very much for taking the time to create the video, it was very helpful and saved me a bundle of money by being able to do the repair myself.Thanks again!!! Dano, Melbourne Fl.

Parts Used:

-

Daniel from Melbourne, FL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!