ALG643RAW Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Dryer heat would go off and timer would not move. Dryer would continuously run

-

chuck from smithtown, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

timer would not turn off drying cycle

unplugged power cord, pulled timer knob off of stem, removed screws at rear of control panel, swung top of panel forward, LEAVE WIRES ON TIMER, used screw driver to release timer lock tab, turned timer to unlock retaining tabs, NOW REMOVE WIRES ONE AT A TIME AND PLACE ON CORRESPONDING TAB ON NEW TIMER, install new timer by placing tabs in openings and turned to lock in proper position, making sure lock tab snapped into place, put panel back in position, replace screws, replace knob on timer stem, plug power cord in, test cycle for operation,CONGRATULATIONS, it works!

Parts Used:

-

Forrest from Dayton, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

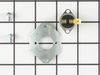

At the end of the drying cycle, the clothes had a bunt smell. I checked the lower compartment of the dryer and found the limit thermostat in two pieces and realized this could be the culprit. I was able to snap them together, but this did not work, therefore a new stat

First I unpluged the dryer, removed the two screws from the bottom access panel. I used a small socket to remove the screws securing the limit stat to the burner chamber, nut driver was too long.

I installed the new limit stat with the two screws and attached the two leads. Plugged in the dryer and conducted a test run, burner ignited. I turned the dryer off and replaced the access panel.

I installed the new limit stat with the two screws and attached the two leads. Plugged in the dryer and conducted a test run, burner ignited. I turned the dryer off and replaced the access panel.

Parts Used:

-

James from Mokena, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door wasn't staying closed

popped up top of dryer -- With pliers squeezed clips on inside of latch - - with screw driver pryed latch out -- just pused new latch in.......... Thanks to parts select for sending part sooo fast.. wife was happy.. Thanks, Dale

Parts Used:

-

Dale from Livingston, TX

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer stoped working

At first i thought i had to buy new dryer, because i did not know what to do.I said, i never done this kind of repair before, well i put everything apart and notice that the idler pulley was worn out, then i said this is something that i can fix it if i get the part. I made several calls and couldn't find it. so went in internet and found it with you.

Parts Used:

-

Roman from Gaithersburg, MD

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My drier would start create heat,than stop heating after 8-10minutes.

After reading the many different common stories,I replaced both coils (m series).Very simply lifted up the top of driver,held by 2 snap springs and 2 lint vent screws.Removed front cover,2 screws and 2 bottom snaps,coils down on bottom left.r/r both coils,reinstalled covers and let there be heat!This website is a blessing!!

Parts Used:

-

Tom from Schaumburg, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeaking motor, over heating, thermal switch kicking out.

Unpluged dryer from outlet, disconnected vent, positioned dryer on side, removed screws from bottom panel, pulled pannel away from dryer body to gain access to motor. Disconnected drum belt from motor pulley, disconnected wire harness from motor. Removed motor mounting bracket assembly and placed entire assembly on floor. Removed clamps and blower assembly from old motor, installed new motor and reassembled. Very easy project, hardest part requires some trouble shooting knowledge to determine the exact cause of problem.

Parts Used:

-

Ernest from Ida, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

5 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Too much drying time, not hot enough

I removed the Drier Door and removed the Front Drier Panel exposing the Gas Valve & associated parts. I removed two (2) screws holding the Gas Valve Coils in place & replaced the 2 terminal coil, then replaced the screws, Front Cover & Drier Door. I liked the results so much, I ordered the other Gas Valve Coil and will replace it also when it arrives.

Good trouble shooting information.

Good trouble shooting information.

Parts Used:

-

John from Floyd, VA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Progressively louder squeaky noise when drying

I followed the instructions found on this site. The hardest part was figuring out how to release the clamps at the front of the dryer so I could remove the top.

The key was to unbolt the clamps at the back of the dryer first, then to use a putty knife to release the two clamps at the front of the dryer that hold the top to the front.

The rest was easy by following the steps already listed on this site and removing the two front pieces, then the drum and replacing the parts. Putting it back together was simple since I placed things in order and had taken pictures with my cell phone as I went through the process.

The time I took, included vacuuming the inside of the dryer thoroughly. Now it runs like new.

The key was to unbolt the clamps at the back of the dryer first, then to use a putty knife to release the two clamps at the front of the dryer that hold the top to the front.

The rest was easy by following the steps already listed on this site and removing the two front pieces, then the drum and replacing the parts. Putting it back together was simple since I placed things in order and had taken pictures with my cell phone as I went through the process.

The time I took, included vacuuming the inside of the dryer thoroughly. Now it runs like new.

Parts Used:

-

George W from Austin, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Wrench set

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Load noise from dryer

Had to figure out how to open the dryer - bottom screws in front and work up, removed the drum and found the fan blade was broken. Had some difficulty removing the fanblade from the motor shaft but after that the new one was easy to install. I did need help to place the belt and drum back into place. as one person has to hold the belts on the pulley while the other adjusts the belt while putting the drum back into place.

Parts Used:

-

Mike from Pacifica, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Socket set, Wrench (Adjustable), Wrench set

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Our dryer was making a loud sound similar to a NYC subway train

Removed all of the front outer bolts holding in the lower plate, front door assembly, drum outer frame and drum. While removing the outer sheel there are colored wire connections that activate the linterior light and door sensors in which I marked the interior sheel with a marker so I knew which wire went where. Before removing the drum I drew a sketch on how the belt is ran thru the pullys and around the drum, so I would have no problem reinstaLLING IT.The rooler bracket was easily removed with a socket wrench and the retaining wring was pried with a pliers. Reinstallation of the shaft, roller and ring were as simple as removal. I then cleaned the entire interior and lint basket for optimal performance. The most difficult part is pulling the belt back around the drum, but still not very difficult. Finally I reattached nall removed parts as they were removed and I now have a like new dryer for about $20.00 vs, buying anew one or repair fees costing Hundred$ OF DOLLERS.

Thanks Partsselect.com Again!

Thanks Partsselect.com Again!

Parts Used:

-

John from Tinton Falls, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

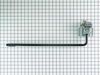

gas burner made a loud buzzing noise when the burner ignited

1) went to internet to find out how to remove the front door panel (no exposed skrews)

2) Two small wire connectors needed to be disconnected

3) The gas burner element required removal of only 4 screws after disconnecting the gas line.

4) replaced everything in reverse order

I am sure I saved about $150 repairing this myself.

2) Two small wire connectors needed to be disconnected

3) The gas burner element required removal of only 4 screws after disconnecting the gas line.

4) replaced everything in reverse order

I am sure I saved about $150 repairing this myself.

Parts Used:

-

george from Yorba Linda, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set, Wrench set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Excessive noise

1.Unplug unit

(gas model, did not shut off)

2. Remove bottom front panel-2bolts

3 Remove main front panel-2 bolts (no need to remove door)

4. Make note of wire colors on door switch and light, disconnect

5. Remove 3 screws that hold air duct assembly(that lint filter rests in) then set main front panel aside

6. Remove lower air duct (to blower motor)-3 bolts

7. Lift and tilt-up top lid/panel of dryer and wedge wood or ? (this will give you easy access and better light)

8. Reach back behind motor to move idler pulley and remove belt from motor & idler pulley

9. Remove 4 bolts and lift up and out front bulkhead frame that holds drum in place

10. Slowly pull straight out & slightly up entire drum

11. Remove circlip/retaining ring, washer, roller, washer and shaft assembly.

12. Vacuum entire unit

13. Light lubricant on shaft when reinstall in reverse order.

Snap ring pliers and a mental note of how the belt is routed on idler will prevent unwanted profanity.

This is an inferior/substandard unit before Maytag bought them. Spend the money and replace both rollers with new shafts (about 50.00). I have spent over 140.00 in parts to keep this unit running (less than 8 years old). So do the math before you start pouring money into this model.

(gas model, did not shut off)

2. Remove bottom front panel-2bolts

3 Remove main front panel-2 bolts (no need to remove door)

4. Make note of wire colors on door switch and light, disconnect

5. Remove 3 screws that hold air duct assembly(that lint filter rests in) then set main front panel aside

6. Remove lower air duct (to blower motor)-3 bolts

7. Lift and tilt-up top lid/panel of dryer and wedge wood or ? (this will give you easy access and better light)

8. Reach back behind motor to move idler pulley and remove belt from motor & idler pulley

9. Remove 4 bolts and lift up and out front bulkhead frame that holds drum in place

10. Slowly pull straight out & slightly up entire drum

11. Remove circlip/retaining ring, washer, roller, washer and shaft assembly.

12. Vacuum entire unit

13. Light lubricant on shaft when reinstall in reverse order.

Snap ring pliers and a mental note of how the belt is routed on idler will prevent unwanted profanity.

This is an inferior/substandard unit before Maytag bought them. Spend the money and replace both rollers with new shafts (about 50.00). I have spent over 140.00 in parts to keep this unit running (less than 8 years old). So do the math before you start pouring money into this model.

Parts Used:

-

John from Ballwin, MO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My lint trap in my dryer broke.

My repair was very easy, the lint trap just comes assembled like when you buy the dryer. However, I had a hard time finding the dryer part at a store.

Part select had the item, they made it really easy to find online. The best part is how fast I received it! My dryer broke the day before thanksgiving (wednesday) i ordered the part that night and had it saturday morning! and thats with thursday being thanksgiving! I didnt even the pay extra for faster shipping! I would use them again and recommend them!

Part select had the item, they made it really easy to find online. The best part is how fast I received it! My dryer broke the day before thanksgiving (wednesday) i ordered the part that night and had it saturday morning! and thats with thursday being thanksgiving! I didnt even the pay extra for faster shipping! I would use them again and recommend them!

Parts Used:

-

Carrie from Hamden, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cylinder Seal came out

Early in the life of my dryer, the Cylinder Seal came out. For the past two years I put off buying the part. When it came in, I p[opped the top of the dryer, removed the two screws holding on the front panel, and pulled the Cylinder of the back wall of the dryer. I then placed the seal in the right spot, glued it down and reassembled. About Fifteen minutes of work and a cheap part, and now my dryer dries a l;oad of clothes in an hour instead of three.

Parts Used:

-

Marcia from Hammond, LA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!