ALG643RAW Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Broken belt

I just followed the intructions from the video on the website. That made the replacement easy.

Parts Used:

-

JOEL from ALTADENA, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Flame would go out after start up. The Igniter would glow not light

Repair itself was not hard, Pop top, unscrew front panel and pull forward to get at the coils under the drum. --THIS IS THE KEY POINT i ENCOUNTERED: I tested the coils and the resistance was right according to the schematic. But still the flame would go out after while. --on a whim I pulled the front cover and tested the coils immediately after the flam wouldn't re-light.---When the coil got warm, it would open (no continuity). When it cooled down again the correct continuity would return. Replaced the coil and no more problem

Parts Used:

-

Jay from South Bound Brook, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Squealing

Pulled the front, loosened the top, released the belt, pulled the tub, pulled the motor, and replaced the idler pulley lever and shaft and the idler pulley wheel, and the belt.

Parts Used:

-

George from Santee, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Dryer had an intermittent squeak, then would shut off before the end of cycle.

Replaced glides, belt, and rollers, but problem still existed. Next, I purchased a new motor and problem solved! Repairing my dryer was easier than I had previously thought it would be.

Parts Used:

-

Steve from Van Buren, MO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

replaced roller wheels/ pulley wheel

I had two repairs, a few days apart while waiting for diagnosis and parts. I watched the videos and followed the steps, simple as that. I was able to replace the rear roller wheels without taking the drum all the way out. I tried the dryer with this 1st fix, some sounds went away but the worst one remained. Took the drum all the way out and replaced the idler pulley wheel just as the video shows. Everything went back together just fine- no extra parts and the dryer is soooooo quiet. My wife thinks I'm a stud for doing this, thank you partselect.com. A caveat, the e rings that hold the wheels on are a big pain to remove and reapply. The snap ring pliers needed to get these off don't always fit in the little openings to remove the ring.Get the smallest size tips if you buy the pliers. My pliers got an "A" for effort, a "D" for results. I used a pair of slotted screwdrivers to manipulate the rings off. Your mileage may vary.

Parts Used:

-

david from manlius, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Dryer making noise

The problem was easy to troubleshoot using the PartsSelect diagnostics on the website. After viewing the instructional videos for the parts I suspected I placed the order. When the parts arrived I reviewed the videos prior to attempting the repair. The problem was a drum support roller. I began by removing the top and front panels. The model I have was older than the video and the only trouble I had was that the top panel was screwed in place instead of clips. Once that was figured out the repair was pretty easy. I removed the drum, belt and replaced the Drum Support Rollers and Drum Glides, installed a new belt and reassembled. The parts for this type of repair are so reasonable that some of the parts I replaced were to insure longer life but actually were not in bad shape. Overall this was a very cost effective and relatively easy repair.

Parts Used:

-

Samuel from Tulsa, OK

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer squeaking, shutting down, and difficult starting.

Motor was replaced with common hand tools, after replacing roller guides and belt.

Parts Used:

-

Steve from Van Buren, MO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!

gas dryer won't ignite

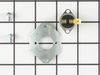

Removed the 2 screws from the lower front cover and removed cover removed the 3 screws from the return air duct and removed duct removed the wires from the gas control coils and started dryer checked for voltage at the wires there was 120 volts present replaced both control coils and limit switch (replaced limit switch because they are a common problem) Happy wife Happy life

Parts Used:

-

Michael from Turner, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer quit heating.

Removed two screws from front panel and lifted front panel away, Turned it to the left so I could keep the door switch connected. The dryer would heat when it was first started, but then the burner would go off and would not come back on. I ran the dryer with the front panel off and could see the igniter glow and light the burner, but after the burner cycled off, the igniter would come back on but the gas would not come back on. I could tell it wasn't the thermostat because the igniter would come on, so I knew it must be the gas valve, and therefore probably the coils. The instructions on the website said that the coils were frequently intermittent, so that seemed like the problem. I tried checking out the coil resistance with an ohmmeter to try to confirm that, but couldn't really tell anything that way. I ordered the replacement coils Tuesday night, selecting the cheapest shipping; they shipped on Wednesday, and were delivered on Thursday! Amazingly fast! Removed two screws from the clip that holds the coils in place, unplugged the old coils, swapped in the new coils, screwed the retaining clip back on. All done. Before I replaced the front panel, I watched to see that it operated correctly. I could see the burner cycle off, then after a bit, the igniter glowed, and then the gas came back on and lit, just like it should. Problem solved. Put the front panel back on, and that's all there was to it. Well, I did vacuum out some of the dust inside the cabinet while I had the cover off. Just out of curiosity, I checked the resistance of the new coils before I installed them to compare with the old ones. Couldn't see much difference.

Parts Used:

-

John from La Crescenta, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

heat cycle runs once then does not come back on

follow Steve the repairman's instructions they were very good

Parts Used:

-

john from garden city, NY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer would not maintain heat

I started with the process of elimination, based on the web site part failure percentage...so I started with the cycling thermostat and thermal fuse, without success. Next, I placed an order for the 'M' Series New Style Coil Kit Part # PS334310. Which, are located behind the lower front panel

Parts Used:

-

Joe from Freehold, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Loud sound

I knew that it have to be worn out roller drums or the idler pulley with bearing. So, I ordered both items. I watched the repair video to know how to do it. I installed the items and the sound disappeared

Parts Used:

-

Angel R. from Kissimmee, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

Was this instruction helpful to you?

Thank you for voting!

Dryer was shacking really bad

I did it just like the man in the video that was sent via e-mail by ParSelect,.

Parts Used:

-

Carlos from Rowlett, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

unusual noises

replaced all above parts, everything seems fine now. Thank You.

Parts Used:

-

Thomas from katy, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Socket set

Was this instruction helpful to you?

Thank you for voting!

Loud squeaking noise especially with larger loads

Used the Parts Select video. I also replaced the drum belt which I had ordered earlier. Repair went exactly as described in video. Belt looked fine but replaced anyway. Rollers and glides needed replaced. (Hint: felt pads for glides had come unglued and fallen to bottom of dryer-this was probably the main problem as glides no longer had support). I reused the same felt pads and glued them to bottom of new glides with Goop. You need O ring compressor and expander for rollers. Drum belt was a little hard to thread at the belt tensioner and video was not real clear. If you use left hand around left side of motor to guide the belt and right hand around right side of motor to compress tensioner, it worked great.

Parts Used:

-

Raymond from Plantation, FL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!