ALG443RAC Amana Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

No heat

Igniter would glow and flame would burn for about 30 seconds then a rattling noise would start and the flame would go out. Replaced the coil and all is well. Very simple and inexpensive. One of the easiest repairs I've ever done. Video was very helpful.

Parts Used:

-

Terence from Plymouth, IN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Sounded like a pair of gym shoes rolling in the dryer

I recently found your site and was pleasantly pleased with your troubleshooting suggestions and repair videos. My dryer was sounding like there was a pair of gym shoes inside bouncing around and your suggestion of the drum support rollers was right on the money. My dryer cabinet came apart a little differently then what the video showed but was workable.

I would like to suggest sending the washers that go in front of and behind the drum support roller with the drum rollers. The washers on my dryer were completely ground down to powder so I drilled out some stainless steel washers I had in my supply of extra parts. These washers are hard to find in a hardware store due to being so thin.

I would suggest to anyone changing these drum rollers to go ahead and order/replace the drum belt and front guides as long as you have the machine apart and had to take these off to get to drum rollers. I have had my dryer maintenance free for 17 years and figured they were probably close to being worn out as well. My front guides were paper thin and the drum belt had lots of cracks.

Total cost of bringing dryer back up to par was only $45.00. Saved at least $180.00 doing myself.

I would like to suggest sending the washers that go in front of and behind the drum support roller with the drum rollers. The washers on my dryer were completely ground down to powder so I drilled out some stainless steel washers I had in my supply of extra parts. These washers are hard to find in a hardware store due to being so thin.

I would suggest to anyone changing these drum rollers to go ahead and order/replace the drum belt and front guides as long as you have the machine apart and had to take these off to get to drum rollers. I have had my dryer maintenance free for 17 years and figured they were probably close to being worn out as well. My front guides were paper thin and the drum belt had lots of cracks.

Total cost of bringing dryer back up to par was only $45.00. Saved at least $180.00 doing myself.

Parts Used:

-

Ronald from Bourbonnais, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

Dryer would not continue to provide heat to dry laundry.

Both washer and dryer always worked perfectly. Suddenly, dryer wasn’t drying laundry properly. Problem... no heat. Cheapest price I could find calling for appliance service was about $160 to replace coil set but no one would tell me this would fix the problem. This was after calling a number of repair firms and trying to get a somewhat close estimate of what my problem was and what the repair cost. Not knowing, I might have just paid the $160 but what turned me off was having a service call fee of anywhere from $50-$80 with no one willing to tell me what the problem might most likely be before coming out or give me an estimate over the phone other than a range of $160 - $275. I just did not want to have someone come out for $50 -$80 and tell me that I needed to spend $275 and still owe them the service call even if I did not agree.

Found diagnostic and repair instructions help on line. The diagnostic information indicated a high probability, roughly 50%, that replacing the coil set would solve the problem and found the coil set cost $19.21 plus shipping, so I ordered the coil kit for total of $26.70. Note... I am a 71 year old amateur never having worked as a repairman of any kind except for my own needs.

The repair itself took less than 30 minutes start to finish and was one of the most straight forward, glitch free, easy repairs I have ever done. This is a gas dryer but still uses 110 power so I unplugged the 110 power cord from outlet. Followed suggested guidance on opening the dryer cabinet from the front and presto, the coil set I needed to replace was immediately right in front with easy access. Removed 2 screws for the hold-down bracket, slipped off both coils, one at a time, removing the wiring connection for each coil and then reconnecting to each new coil before slipping each new coil back into place and reattaching the hold down bracket. Reinstalled the dryer door and cabinet front in reverse order from taking off... 4 screws total. Plugged in the 110 power cord and put in a damp load of freshly washed laundry. Presto... 30 minutes later... dry laundry. Note... could do the same repair again in half the time since I took it slow and careful 1st time and also took time to remove dust before completing repair. I like things to look like new inside and out and it did when I was done. $26.70 and good as new. Why I didn't spend $160 - $275 is pretty obvious now.

Found diagnostic and repair instructions help on line. The diagnostic information indicated a high probability, roughly 50%, that replacing the coil set would solve the problem and found the coil set cost $19.21 plus shipping, so I ordered the coil kit for total of $26.70. Note... I am a 71 year old amateur never having worked as a repairman of any kind except for my own needs.

The repair itself took less than 30 minutes start to finish and was one of the most straight forward, glitch free, easy repairs I have ever done. This is a gas dryer but still uses 110 power so I unplugged the 110 power cord from outlet. Followed suggested guidance on opening the dryer cabinet from the front and presto, the coil set I needed to replace was immediately right in front with easy access. Removed 2 screws for the hold-down bracket, slipped off both coils, one at a time, removing the wiring connection for each coil and then reconnecting to each new coil before slipping each new coil back into place and reattaching the hold down bracket. Reinstalled the dryer door and cabinet front in reverse order from taking off... 4 screws total. Plugged in the 110 power cord and put in a damp load of freshly washed laundry. Presto... 30 minutes later... dry laundry. Note... could do the same repair again in half the time since I took it slow and careful 1st time and also took time to remove dust before completing repair. I like things to look like new inside and out and it did when I was done. $26.70 and good as new. Why I didn't spend $160 - $275 is pretty obvious now.

Parts Used:

-

Nick from Surprize, AZ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Was not drying well

I first replaced the temperature sensor. That did not help and when doing investigation when thr drier was warm I found the vallve would open and close if I touched the coils

Parts Used:

-

Carol from Ada, MI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!

Loud squeal and squeek

took dryer apart and replaced the drum support rollers. This did not work and problem is still there. The videos at the part select did not help since they seemed to be for a different dryer and nothing in them helped in any way to work on my unit. I did get a repair man out and was told that he had not seen one built like this one before.

Parts Used:

-

Curran from Cadiz, KY

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

The dryer had been making the occasional squealing sound for the last year or so, but on it's last use the volume of the squealing increased dramatically along with a new "banging".

The front of the dryer disassemled a bit differently than the video, but once I came to the conclusion I was going to rip it apart, I figured out how it needed to be done. That added about 5 min. to the repair. The main culprit was the idler pulley, it was nearly completely frozen, but I had ordered all the most likely components, so I also changed out the rear support rollers & front glides. The belt was actually in pretty good shape, but I swapped it out also so I wouldn't have to do it in the (near) future. I had to take a 2nd look at the video for belt routing on reassembly. Without tension on the belt it doesn't look like it would work, but once the tension is added the the belt separates so it's not rubbing on itself, like it would appear to do before being tensioned. All and all it was a fairly easy fix and for $47 incl. shipping, much cheaper than a new dryer or even a service call... Thanx

Parts Used:

-

Matthew from Englewood, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Broken belt

I just followed the intructions from the video on the website. That made the replacement easy.

Parts Used:

-

JOEL from ALTADENA, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Flame would go out after start up. The Igniter would glow not light

Repair itself was not hard, Pop top, unscrew front panel and pull forward to get at the coils under the drum. --THIS IS THE KEY POINT i ENCOUNTERED: I tested the coils and the resistance was right according to the schematic. But still the flame would go out after while. --on a whim I pulled the front cover and tested the coils immediately after the flam wouldn't re-light.---When the coil got warm, it would open (no continuity). When it cooled down again the correct continuity would return. Replaced the coil and no more problem

Parts Used:

-

Jay from South Bound Brook, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Squealing

Pulled the front, loosened the top, released the belt, pulled the tub, pulled the motor, and replaced the idler pulley lever and shaft and the idler pulley wheel, and the belt.

Parts Used:

-

George from Santee, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Dryer had an intermittent squeak, then would shut off before the end of cycle.

Replaced glides, belt, and rollers, but problem still existed. Next, I purchased a new motor and problem solved! Repairing my dryer was easier than I had previously thought it would be.

Parts Used:

-

Steve from Van Buren, MO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

replaced roller wheels/ pulley wheel

I had two repairs, a few days apart while waiting for diagnosis and parts. I watched the videos and followed the steps, simple as that. I was able to replace the rear roller wheels without taking the drum all the way out. I tried the dryer with this 1st fix, some sounds went away but the worst one remained. Took the drum all the way out and replaced the idler pulley wheel just as the video shows. Everything went back together just fine- no extra parts and the dryer is soooooo quiet. My wife thinks I'm a stud for doing this, thank you partselect.com. A caveat, the e rings that hold the wheels on are a big pain to remove and reapply. The snap ring pliers needed to get these off don't always fit in the little openings to remove the ring.Get the smallest size tips if you buy the pliers. My pliers got an "A" for effort, a "D" for results. I used a pair of slotted screwdrivers to manipulate the rings off. Your mileage may vary.

Parts Used:

-

david from manlius, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Dryer making noise

The problem was easy to troubleshoot using the PartsSelect diagnostics on the website. After viewing the instructional videos for the parts I suspected I placed the order. When the parts arrived I reviewed the videos prior to attempting the repair. The problem was a drum support roller. I began by removing the top and front panels. The model I have was older than the video and the only trouble I had was that the top panel was screwed in place instead of clips. Once that was figured out the repair was pretty easy. I removed the drum, belt and replaced the Drum Support Rollers and Drum Glides, installed a new belt and reassembled. The parts for this type of repair are so reasonable that some of the parts I replaced were to insure longer life but actually were not in bad shape. Overall this was a very cost effective and relatively easy repair.

Parts Used:

-

Samuel from Tulsa, OK

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer squeaking, shutting down, and difficult starting.

Motor was replaced with common hand tools, after replacing roller guides and belt.

Parts Used:

-

Steve from Van Buren, MO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!

gas dryer won't ignite

Removed the 2 screws from the lower front cover and removed cover removed the 3 screws from the return air duct and removed duct removed the wires from the gas control coils and started dryer checked for voltage at the wires there was 120 volts present replaced both control coils and limit switch (replaced limit switch because they are a common problem) Happy wife Happy life

Parts Used:

-

Michael from Turner, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

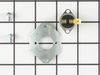

Propane dryer burner comes on for a couple of seconds then off

I looked at a couple of videos on U tube. Then ordered the parts ($43 total). First put in the High Limit thermostat (really a bimetal circuit brkr). Dryer tested good (that part was only about $7). But since I also ordered the Limit Thermostat (I think this just sets the temperature by regulating burner on time) I put that part in also and retested. All tests good. A repair house call costs $75 around here and that doesn't even include parts and maybe a revisit to install them. Simpler and cheaper for me to replace $43 total in parts. Dryers are simple devices. It ain't rocket science.

Parts Used:

-

Ronald from Coarsegold, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!