7MMMS0120VM0 Maytag Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Factory hose wore thin over time and water pressure caused blowout

Very easy replacement. The new hose was more like a formed radiator hose and fit exactly.

Removed two screws at rear of control panel and separated the rear cabinet panel from the front cabinet enough to get to the water valve. I then disconnected the break hose from the valve by compressing the spring clamp. I then disconnected the other end from the washer water inlet by also releasing another spring clamp.

The new hose was installed using the same clamps. The cabinet was reassembled and washer tested for leaks.

Removed two screws at rear of control panel and separated the rear cabinet panel from the front cabinet enough to get to the water valve. I then disconnected the break hose from the valve by compressing the spring clamp. I then disconnected the other end from the washer water inlet by also releasing another spring clamp.

The new hose was installed using the same clamps. The cabinet was reassembled and washer tested for leaks.

Parts Used:

-

Joseph from PLANO, TX

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Was heavily shaking.

Old machine and vibrations are still there but weaker. Seemed to turn counter clock wise. Put a 4x4 board behind in order to stop the twisting, and keep hoses safe from vibrating and causing wear. Stays fairly stable now.

Parts Used:

-

Robert from LEWISTON, ID

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

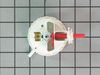

The water level switch was not working properly

I ordered the part and replaced it. It was very easy to do..I am not mechanical at all and I was able to do the repair

Parts Used:

-

Richard from COPIAGUE, NY

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Brake cam broke.

-

JOHN from MUSKEGON, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would not start consistently when lid was closed. Water filled, but cycle would not start

Unplug the washer. Used flat blade screwdriver under each end of the control housing on top of the machine. This popped the spring clips and allowed the control housing to be lifted up and rotated out of the way. Once out of the way, lift clip on wiring harness to lid switch, then pull the harness off. Use nutdriver to remove screw holding ground wire in place. Open lid of the machine. Pinch tab on back of the lid switch and rotate the switch up and out of the machine. Insert the new switch in the same manner, making sure that the machine lid remains open until the switch snaps into place. Attach ground wire using screw removed earlier and nutdriver. Clip wiring harness back in place. Close the lid and then rotate the control housing downward, and press on both ends to re-engage the spring clips which hold it down.

Parts Used:

-

Jessica from Jewett, NY

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Machine made loud banging noise and vibration when running and tub ran off center

Disassembled top control console and surrounding sheet metal cabinet per the video from this site. i then used a screw driver to carefully pry up each wear pad location individually and inserted the wood wedge. to about 1 1/2 inch height. rwmoved the old wear pads and popped in the new pads one by one. Closed up the unit and tested the machine . It ran like new. No more noise or viberation

Parts Used:

-

Albert from ROSELLE, IL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

clothes remain soaking wet after wash cycle

The video was well made and made repair easy. I like the fact the video also showed how everything went back. The most difficult part and most time consuming for me was putting the washer cabinet or housing back on. I had a hard time lining the sides onto the slot to lock in place....the minor cut on finger sustained during the process was worth it. It saved me from buying a new washer and the whole family are happy that they don't have to wring out the clothes before putting it the dryer. Thank you!

Parts Used:

-

MICHAEL from lake elsinore, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drain Hose had a crack that leaked...

Unplugged the electrical plug and turned off the water. Used putty knife to remove control box. Unplugged the washer lid switch. Used screwdriver to remove clips to washer cover. Removed cover out of the way. Removed clips that hold the drain hose on the washer frame. Used Pliers to open the clip that holds the drain hose on the discharge pump. (You will need to re-use this clip) Removed the bad drain hose. Installed new hose with clip to discharge pump. Clipped in new drain hose to the washer frame. Re-installed washer cover and re-clipped brackets. Re-plugged lid switch and re-installed the washer control box. Turned on the water and energized the washer. Ran a test load and checked for leaks.

Parts Used:

-

Mark from MONTEREY PARK, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

One spring holder came out with the old spring

We had to take the motor off and find the part that holds the spring, took longer to fix as we are older people and took a brake after every spring. We used YouTube videos to help us I am thankful for this site and cheap prices.

Parts Used:

-

Dave and mary from DURAND, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would not spin

Based on all the other info here, I thought "ah-ha! I need to replace the clutch assembly". So I ordered the part, it came the next day (to Vermont, even!) and started to disassemble the agitator, motor, etc. just as shown in the video. I don't think I would have attempted it if it had not been for the video. It made the process seem very straightforward and easy, as long as you are comfortable using a socket set.

That said, there were some fairly minor differences between my machine and the one in the video, so your repair might differ a little. First of all, I did not need one of those spanners / tub wrenches (whatever they called it in the video-- the thing he hit with the sledge hammer) to take off that nut under the agitator. I didn't need to remove it, and the drive axle just pulled right out. Second, you really don't need to remove the motor mount. Just take the motor off, and then go right to removing the three bolts on the transmission.

Actually, my problem turned out to be NOT the clutch assembly, but the little plastic gear things that go between the motor and the transmission, fitting into that rubber ring thing. I lifted the motor off and one of them was sitting there in pieces! You can easily order this part, and it's even easier to install than the clutch assembly. The plastic pieces are reinforced with metal now, which seems like a good idea.

All in all, this was a fun little project, and now I am under the (probably false) impression that I can repair any problem with washing machines!

That said, there were some fairly minor differences between my machine and the one in the video, so your repair might differ a little. First of all, I did not need one of those spanners / tub wrenches (whatever they called it in the video-- the thing he hit with the sledge hammer) to take off that nut under the agitator. I didn't need to remove it, and the drive axle just pulled right out. Second, you really don't need to remove the motor mount. Just take the motor off, and then go right to removing the three bolts on the transmission.

Actually, my problem turned out to be NOT the clutch assembly, but the little plastic gear things that go between the motor and the transmission, fitting into that rubber ring thing. I lifted the motor off and one of them was sitting there in pieces! You can easily order this part, and it's even easier to install than the clutch assembly. The plastic pieces are reinforced with metal now, which seems like a good idea.

All in all, this was a fun little project, and now I am under the (probably false) impression that I can repair any problem with washing machines!

Parts Used:

-

Brant from Saxtons River, VT

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cold water would not flow into washing machine

I disconnected the water lines and pulled the washing machine over so it was lying on its front. I removed two screws on the bottom edge of the back, and then puzzled over how to get the back off. I ended up removing the screws that held the control panel on, removing the wiring harness, and taking the control panel/head off. This exposed two metal clips that I was able to unhook. I unhooked the water valve from the back, disconnected the electrical connections, removed the water line, and replaced the valve. Then I puzzled about how to put it back together for a bit, and basically just reversed the order I took it apart.

Parts Used:

-

Brian from Saint Clair Shores, MI

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

5 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer wouldn't come on, power turned on but no action

removed the top cover (with all the knobs on it) by releasing the holds in the back

removed the screw holding the lid in place

pinched the snap and removed the part

pinched the snap on the new one and seated in in the hole

screwed in the screw (lol)

turned on the washer

removed the screw holding the lid in place

pinched the snap and removed the part

pinched the snap on the new one and seated in in the hole

screwed in the screw (lol)

turned on the washer

Parts Used:

-

james from Cumming, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator seperated from inside of wash drum

I had to find a point of reference first since item came apart in wash cycle and internal pieces fell out - thank goodness for YOUTUBE. Another guy was thoughtful enough to do a video on how the assembly came apart / went back together - a huge help for sure. Actual repair was less than a half hour after obtaining new part and seeing video. The 12 year old washer works like brand new - saving me close to 1,000 dollar replacement charges.

Parts Used:

-

Larry from Brandon, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water continued to drip in tub after load finished.

Kenmore 11027721600 washers repair & replacement parts

Part Number WP3979346 replaces: 3979346, 3979347, 8578342, WP3979346VP.

Post drip from water inlet

To replace the inlet solenoid valve/thermistor assembly:

Unplug the washer.

Turn the water off and unscrew the hoses from the inlet.

Use a putty knife to release the control panel (slide the putty knife under the front corners to release the clamps on the control panel).

Pull the panel out of the way and pop out the two retaining clips that hold the back of the machine to the cabinet. They are located under the control panel.

Remove the mounting screw from the valve assembly (1/4-inch driver).

Pull the back away from the cabinet far enough to remove the valve, but don't let the wires get cut.

Disconnect the wires. To unplug the solenoid connectors, lift the long tab with a screwdriver.

Disconnect the water outlet hose.

Connect the wires and hose to the new valve assembly. The red connector goes to the hot water valve. The thermistor wires (the two individual connectors) can be connected to either terminal. It does not matter if they are reversed.

Put the valve back in place and install the screw.

Hook up and turn the water on.

Plug in the machine and test the valve.

Unplug the power and reinstall the back and the control panel. The back-to-cabinet clips can be snapped back in place easily.

Part Number WP3979346 replaces: 3979346, 3979347, 8578342, WP3979346VP.

Post drip from water inlet

To replace the inlet solenoid valve/thermistor assembly:

Unplug the washer.

Turn the water off and unscrew the hoses from the inlet.

Use a putty knife to release the control panel (slide the putty knife under the front corners to release the clamps on the control panel).

Pull the panel out of the way and pop out the two retaining clips that hold the back of the machine to the cabinet. They are located under the control panel.

Remove the mounting screw from the valve assembly (1/4-inch driver).

Pull the back away from the cabinet far enough to remove the valve, but don't let the wires get cut.

Disconnect the wires. To unplug the solenoid connectors, lift the long tab with a screwdriver.

Disconnect the water outlet hose.

Connect the wires and hose to the new valve assembly. The red connector goes to the hot water valve. The thermistor wires (the two individual connectors) can be connected to either terminal. It does not matter if they are reversed.

Put the valve back in place and install the screw.

Hook up and turn the water on.

Plug in the machine and test the valve.

Unplug the power and reinstall the back and the control panel. The back-to-cabinet clips can be snapped back in place easily.

Parts Used:

-

Darline from Dunn, NC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The tub was filling when the washer was off

I removed the control panel and a few screws on the back took out the valve.the new one was different but I made a bracket and got it to fit

Parts Used:

-

kevin from RUSH CITY, MN

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!