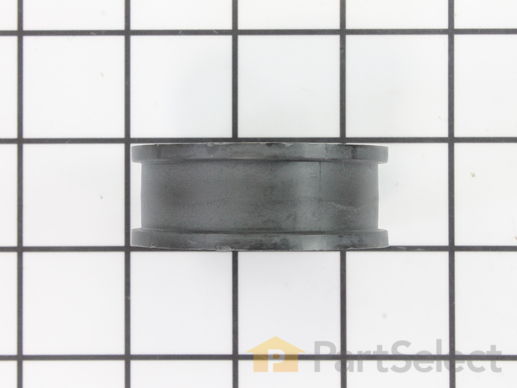

Idler Pulley Wheel with Bearing WPY54414

Rated by 68 customers

Easy

1- 2 hours

Ratings submitted by customers like you who bought this part.

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

Idler Pulley Wheel with Bearing Specifications

How Buying OEM Parts Can Save You Time and Money

Replacing your Amana Dryer Idler Pulley Wheel with Bearing

-

5 Stars 16

-

4 Stars 3

-

3 Stars 0

-

2 Stars 0

-

1 Star 1

- < Prev

- 1

- 2

- Next >

- < Prev

- 1

- 2

- Next >

- < Prev

- 1

- 2

- 3

- Next >

Removed door assembly* making note of the wire positions on the door switch

* When removing the door assembly DO NOT LET IT DROP DOWN! Doing so will destroy the door switch. Swing the door assembly upward from the bottom toward you as high as it will go then pull it free.

Removed the d ... Read more rum and belt assembly.

Removed the idler pulley and idler pully spring.

Vacuumed up the interior dryer floor and blew out the motor w/ comp air. Also cleaned the ribbed motor pulley with a nylon brush and brake cleaner sprayed on a shop towel.

Removed the drum tires and cleaned their shafts and internal bearing sleeves with brake cleaner sprayed on a shop towel.

Reinstalled the drum tires after lubricating their shafts with a very light coat of general purpose grease.

Replaced the idler pulley and idler pulley spring after cleaning and lubing shaft and pulley bearing as done on the drum tires.

Reinstalled the drum with the new belt (ribbed side down) roughly in place.

Reinstalled the front door assembly after reconnecting it's wiring making sure to insert it's top locking tabs with the bottom of the door held up high then swung down into place

Tensioned the belt by positioning the flat side of the belt that comes down the right side of the drum over the idler pulley flat side down and then the ribbed side of the belt over the motor shaft. You will have to move the idler pulley arm to apply full tension against the spring in order to have the slack to get it around the motor shaft.

Reinstalled the lower front panel.

Checked dryer operation OK.

This repair was rated a bit difficult because I didn't know the trick for removing/installing the door assembly and destroyed the switch. Furthermore, putting the belt back on is a somewhat difficult challenge because you have to do it mostly by feel

-

Stephen from LEANDER, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

-

Joseph from LAGRANGE, IN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

-

Diego from DORAVILLE, GA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

-

George from WORTON, MD

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Socket set

-

Ken from POMPTON LAKES, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Keith from CARLISLE, IA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

-

Gary from Pocono Lake, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

-

shaun from EVANSVILLE, WI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

-

Steven from EUGENE, OR

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver

-

James from NEW HOPE, MN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

- < Prev

- 1

- 2

- 3

- Next >

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- Next >

2 people found this helpful.

2 people found this helpful.

1 person found this helpful.

1 person found this helpful.

1 person found this helpful.

- < Prev

- 1

- Next >

Manufacturer Part Number: WPY54414

Item is in stock and will ship today if your order is placed before 4:00 PM Eastern Standard Time.

If your order is placed after 4:00 PM EST, the in stock items will ship on the next business day.

Item is not in stock and usually ships 3-5 business days from the time you place your order.

Item is not in stock and usually ships 10-15 business days from the time you place your order.

This item is no longer being made by the manufacturer, and cannot be added to your shopping cart.