WWTW3000KW0 Westinghouse Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

the belt was all worn out , it make a lot of noise

i took out the two back screws lift the top.

took the two bottom front screws , lifted andtook off the front panel.took off the old belt an intall the new one in a circular motion put the panel and top back on and done.

took the two bottom front screws , lifted andtook off the front panel.took off the old belt an intall the new one in a circular motion put the panel and top back on and done.

Parts Used:

-

CARLOS from BEALETON, VA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

26 of 38 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

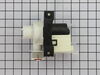

Machine would not spin.

Once I figured out that it would not spin because it did not drain. Unplug machine and remove the back pannel. Locate the drain pump on the bottom of machine. Remove the power wires and the screws holding it to the bottom. Then use a pliers to remove the hose clamps ( was easer for me to tip the machine forward ). Be prepaired to catch or soak up extra water from lines. The hardest part to the install is the limited room you have to work with. Install screws to hold the pump in place then install water lines, power wires and back pannel. Only thing left is to plug it in and watch for leaks.

Parts Used:

-

Jeff from Weyauwega, WI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

20 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Tub wouldn't drain

First I removed the front panel,then set the timer to run. It began the drain,spin cycle, pump ran, but no water went out. Shop-vac the water out,removed hoses from pump,took out mounting screws from base, unplug pump plug. check hoses for debris since they're open, the impeller was broken. ordered the part . Mount the pump to the base, put the hoses on, plug in motor and replace front panel. plug into wall

Parts Used:

-

Brian from Murfreesboro, TN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

19 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Final Spin Burning Smell

Removed 2 screws at bottom of the front panel - removed front panel by sliding the panel down about 1/2 inch and then away from the appliance- v belt is removed by pushing the tensioner pulley to remove tension from the belt and turning the pulley untill the belt is removed instalation is a simple reverse of the process. I did't have a repair manual so every step was trial and error untill I was able to complete the repair.

Parts Used:

-

NELSON from MAYWOOD, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench (Adjustable)

17 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water Flooded Floor

First I took sides off the washer. I then took screws out of the Drain pump holder. Unclamped the two pipes from it. Undid the wires to then drain pump. Screw in the new pump hardware. Plugged in the wires on side of the pump. Reclamped the pipes. Put sides back on washer and it worked. That easy and took less then 30 minutes. I am no handy man so thats how easty it was.

Parts Used:

-

Matthew from Weyers Cave, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

18 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burning smell, lots of hi-pitched squeaking

I got online and figured out exactly how to take off the front of the washer and then how to replace the belt. It was so easy. The part itself arrived much sooner than predicted. It fit perfectly and my washing machine is now running smoothly and quietly.

Parts Used:

-

Heather from Stephenville, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

17 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Stopped agitating versus level washer feet/leg

My washing machine stopped agitating and spinning and I couldn't afford a repair man...plus I wanted to exhaust any obvious problems first. One of the leveler feet had broken years ago. Since I luckily had determined via reading other posts that the agitator won't work if the cycle safety switch is not functioning right, I thought the safety switch might need to be changed but after careful thought, I decided to order a new levelling leg first because maybe the broken levelling leg was shaking the safety switch so it wasn't connecting right. Once I received the leg overnight, I flipped the washer on its side and had to drill out the old leg. It was a little tricky because of how it broke, but the drill worked. I flipped the washer back up, leveled it with the new foot, and the agitator was miraculously working again...just like new. I didn't need the safety switch. Thanks to partselect.com for having the details of my washer parts to study up on and get me the right part so quickly. I saved myself alot of money.

Parts Used:

-

Sandra from Denton, TX

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

17 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the pump had died

First I removed the two screws that hold the pump in place. I then pulled the pump out and replaced it with the new pump.

Parts Used:

-

loudvik from glendale, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

15 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washing machine wouldn't drain

i removed the front panel, then removed the old pump by taking off the clamps and disconnected the wiring. The new pump had to be reversed before connecting, but it was so easy.

Parts Used:

-

Siobhain from Ashland, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

11 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer belt broke

-

Carl from Boxford, MA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

11 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Tub was leeking

Lifted top

removed adgetator

removed tub top

removed inside tub

removed inside tub holder bracket

repaced seal

replaced,replaced.....

removed adgetator

removed tub top

removed inside tub

removed inside tub holder bracket

repaced seal

replaced,replaced.....

Parts Used:

-

Gregory from Fort Worth, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

13 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer went into spin mode but would not spin

I removed the front panel to see the belt was snapped in two. The front roller is sping loaded, so I gave it a little tention, slid the belt back on and viola! it was that easy. If your washer starts to vibrate more and sounds louder than normal, get a belt as soon as possible because that may be the problem. Once I put on the new belt, the machine ran as quiet as it did when I first bought it.

Parts Used:

-

Damon from Hinesville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

9 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wash tub would not drain/burning rubber smell

I removed the top of the washer by removing two screws on the back. I located and bypassed the lid switch to make sure that wasn't the problem. The problem still existed so I removed the two screws that hold the front panel of the washer. Using a flashlight, I located the drive belt and immediately saw that it was out of position and had pieces missing. I cut and removed the old belt, placed the new belt on the tub pulley and slowly maneuvered it onto the motor drive wheel. I then squeezed the tensioner pulley so that the belt was seated. I turned the timer dial which started the washer and it immediately began pumping the water out of the tub. Problem solved!

Parts Used:

-

Clay from Kansas City, MO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

9 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Spin Cycle wouldn't work

Replaced pump, by removing back panel and removing the two screws holding the pump to the bottom of the machine. The only difficult aspect was dealing with the hose clamps, these were extremely awkward to work with in a confined space. The repair would have been less than 30 min if the hose clamps weren't so difficult to put back in place.

Parts Used:

-

KEITH from BEND, OR

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

9 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

water continually leaking into tub when not in use

Repair was harder than originally anticipated. Front had to be taken off, but trying to get all panels back in place was quite a job

Parts Used:

-

D from Baytown, TX

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!