WTW8200YW0 Whirlpool Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Making noise when spinning tub hit side of washer.

Remove top of washer suspension

Rod goes on side of tub .

Rod goes on side of tub .

Parts Used:

-

Ernestine from CARRIERE, MS

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Whirlpool cabrio would not go into the spin function without triggering an error code of 5d

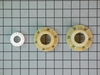

Removed the center cover of the agitator with a flathead. Removed the nut of the agitator main cover. Had trouble taking the cover off because of the crud holding it down I wiggled it up gently alternating n,s and e,w until I eventually saw it separating from the bottom of the basket. Once it came off you could see how nasty the old hub assembly looked. Took the screws off the old hub assembly and removed it. Matched it up with the correct new hub assembly cause the kit comes with 2. Cleaned the shaft and that general area. Installed the new hub assembly, replaced the covers. Ran the drain and spin cycle and it worked with no problem. There are videos on YouTube that show you too. DO NOT try to pry the agitator cover if it won’t rise up easily. Be patient and it will come out.

Parts Used:

-

Victor from HOUSTON, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cold water leaked into tub

Replaced water inlet valve. Parts select video was incorrect for my unit. There are no spring clips to be released using a putty knife. Rather remove the two screws in the back of the top, pull the top forward and up to get at hose connections to the valve. Hint, place a towel under the valve connections because after removed from the valve, the hoses will leak to the floor. I propped the top up with a stick. All the other stuff in the video is good. Unplug and turn water off, remove connectors from old valve etc. . I also removed the protective plate over the cabled that runs between the washer and the control panel located on the back of the washer. The will make the sliding of the top forward easier. Only one screw involved.

Parts Used:

-

Benjamin from FLINT HILL, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

F51 error code

Pretty easy! Just follow this link on how to fix the problem:

https://www.youtube.com/watch?v=_-Hg8rLGiKQ

The hardest part on fixing this is trying to move the washer out of its place so I can tilt it to see underneath the washer where the repair would be.

https://www.youtube.com/watch?v=_-Hg8rLGiKQ

The hardest part on fixing this is trying to move the washer out of its place so I can tilt it to see underneath the washer where the repair would be.

Parts Used:

-

Edgardo from SALEM, OR

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer making lot of noise during spin cycles

Removed agitator and basket hub parts and cleaned all parts of agitator then replace basket hub with new basket hub kit according to video ran washer but did not solve problem

Parts Used:

-

Michael from SAVANNAH, MO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Socket set

6 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water streaming from under lid down front of washer

The inlet/diverter valve relacement steps:

1. Turn off electric and water supply and disconnect hoses

2. Remove hold down screws on back of control console

-Remove console to access valve and remove valve hold down screws

3. Label and disconnect valve connections

4. Insert putty knife 3 in. from each front edge to release hold down clips for top panel.

5. Disconnect hoses from valve assembly.

6. Remove old valve and install new.

1. Turn off electric and water supply and disconnect hoses

2. Remove hold down screws on back of control console

-Remove console to access valve and remove valve hold down screws

3. Label and disconnect valve connections

4. Insert putty knife 3 in. from each front edge to release hold down clips for top panel.

5. Disconnect hoses from valve assembly.

6. Remove old valve and install new.

Parts Used:

-

Martin from FRONT ROYAL, VA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noisy during spin cycle

Repair was pretty straight forward with the exception of removing the agitator. Hint, do not force it, just continue to work it until it releases. Problem was not entirely corrected, but improved.

Parts Used:

-

Robert from ORLANDO, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Stripped screws on a hub drive replacement

Getting to the actual hub is a bit difficult as it involves removing the accetuator and takes some time and patience, but when I tried to replace with a new hub, I found that the screws were stripped, so PartSelect walked me through the ordering process and helped me choose the exact size screws that I needed. Parts came quickly...I already had the hub waiting to be secured and the screws tightened easily. (We had tried using a similar size, but you REALLY need the whirlpool screws that go in there) No more spinning problems, and the machine is not jumping around anymore. Works just like before. This particular machine has to have this part replaced at least twice a year (luckily it's cheap),but saves us from having to buy a whole new machine. My son also told me that since I replace the part so often, best to replace the screws every other time as well.

Parts Used:

-

Bruce from GLOBE, AZ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud banging during wash cycle

This is an easy one. Snap off the agitator cap with a screwdriver.

Remove the single but and agitator.

Remove 6 phillips head screws.

Lubricate the bearing and coax it off the spindle.

Remove the single but and agitator.

Remove 6 phillips head screws.

Lubricate the bearing and coax it off the spindle.

Parts Used:

-

HARRY from BEND, OR

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer walking during spin cycle

Watched video and followed instructions. Removed rods from top cups, laid washer on its side and pulled them out. Put new rods thru, stood washer up and hooked them in. Was pretty easy, tube heavy but I'm 52 and I did it myself.

My only problem is there's no springs anywhere attaching rods to tub and I cannot find any info on 1. IF I need them 2. What kind I need. I sent email to partselect last week inquiring and still waiting to hear.

My only problem is there's no springs anywhere attaching rods to tub and I cannot find any info on 1. IF I need them 2. What kind I need. I sent email to partselect last week inquiring and still waiting to hear.

Parts Used:

-

Tricia from HARLEYSVILLE, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

On Spin cycle washer jumping all over the place.

-

Tuan from LADSON, SC

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud banging during spinning

Followed video provided by Part Select. Video made it look easier than it was but was very thorough and I was able to accomplish repair in less than an hour! The agitator before repair would bounce up and down when I pressed hard and let go. After repair it was much tighter!! Evidently this is a common problem with this design of Whirlpool washers!

Parts Used:

-

Tom from LONG BEACH, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My washer was always off balance.

I used a jack to lift the tub and unhooked the rods and replaced them. Works great.

Parts Used:

-

Tracy from CONWAY, AR

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

out of balance

-

Charles from ARVADA, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

"dL" error code on display. Lid lock mechanism not working.

This was the second time I did this repair, so it looks like this mechanism lasts about 3 years. I found the video instructions on your website very helpful, with one major exception. On my Maytag Bravos XL machine, there are no clips on the front of the top plate to release by pushing in a putty knife. Rather, there are two vertical brackets on the back of the top plate that are loosened or removed, and then the top can be slid forward about an inch and lifted up.

Also, the tiny electrical connection plugs are secured by plastic clips on the sides of the receptacles. Those clips just need to be spread apart a little in order to unplug the connectors; i.e., don't pull too hard on those plugs, or look for a release lever on the plugs themselves.

Repair is straight-forward. Thanks!

Also, the tiny electrical connection plugs are secured by plastic clips on the sides of the receptacles. Those clips just need to be spread apart a little in order to unplug the connectors; i.e., don't pull too hard on those plugs, or look for a release lever on the plugs themselves.

Repair is straight-forward. Thanks!

Parts Used:

-

Bruce from WOODSTOCK, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!