WTW7600XW1 Whirlpool Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Washer entered spin cycle, but would not spin.

The washer would enter the spin cycle, but after starting to spin, would quit, and beep repeatedly. The fault code shown was DL. The manual cited DL as Door Lock malfunction. A check of the door lock switch suggested an internal problem. Sears offered the part at a far greater price, and shipping was several times more than PartSelect.com. PartSelect was chosen, and the part ordered on-line. Within two days the part arrived. Installation was simply a matter of lifting the top of the unit on which the door is supported. IT is done by inserting a narrow screwdriver into the separation, and pressing on the two metal springs holding the top in place. The old part was simple to remove by extracting two phillips head screws and removing the cable from the cable mounts underneath the top surface then threading the cable and plug back through the cable hole. Before that could be completed, the rear cover of the control panel was also removed, and after the plug of the defective switch was removed, the new cable was connected, and threaded back through in the reverse of the removal of the old switch, the phillips head screws, the control panel rear cover and returning the unit top to the resting position and snappin it into place. The Power ON check indicated that the problem fault code was cleared. The unit functions normally with the new switch. Hats off to PartSelect. The part was available in stock, and shipped promptly, and at substantially less cost than Sears.

Parts Used:

-

Paul from Rio Vista, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water pump was busted.

Just pulled the old water pump off and replaced with new one and was good to go. Thank you so much for sharing the problems and how to fix. Dean

Parts Used:

-

William from MAGNOLIA, MS

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Wrench set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

mins after start it stopped and got code f51. then put it manual spin and got UL code

followed repair manual for code f51.ordered/replaced Rotor Position Sensor {RPS} disconnected and reconnected wiring harness at computer module and then put everything back together and that took care of the problem, It;s been working good since. that sensor was delivered the very next day. that was great. thank you

Parts Used:

-

victor m from campo, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

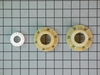

The agitator was making grinding noises

Removed the softener dispenser and cap that's under it. Used 7/17" socket with an 18" long extension to reach the bolt that holds agitator down. Pulled auger off, pulled lower agitator off. Removed the 6 philips head screws that hold basket hub in place. Removed hub and installed new one, replaced screws. Lightly greased spline and reinstalled lower agitator. The auger has the cam section in it. A trick to get the rollers in place is to secure them to the cam with rubber band. Have string tied to the band. Insert the cam and when almose all the way in, pull rubber band off and the rollers stay in place. Reinstalled the bolt, cap and softener dispenser.

Parts Used:

-

Mark from Erie, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

2 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken hinge pin.

-

Kevin from Tucson, AZ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

machine gives uneven load alarm and f51 error code

Tilt the machine over to access the bottom I rested it on a dolly.remove the rotor with an allen wrench .then rmove the 4 bolts on the stator .then lift it off the main shaft and unlug the sensor wires . just reverse the process to install the new one (be sure to allign the arrows on the sensor and the stator when reistalling. I wish i could say this solved my problem .my machine runs untill the spin cycle then it starts shaking and gives the uneven load alarm again.

Parts Used:

-

Charles from Houston, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

Was this instruction helpful to you?

Thank you for voting!

Water would not drain

I read the directions on this web site and was able to install the new drainage pump in about 30 minutes. I suprised myself. Thanks.

Parts Used:

-

Neil from Onalaska, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Won't drain the water

-

Jose from Verobeach, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Socket set, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Hinge pins were sheared off

I removed the screws holding the broken hinges and put the new hinges on. It only took a few minutes.

Parts Used:

-

James from Carrollton, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Lid lock not engaging.

Unplug washer. Use scraper to depress spring steel catches under top cover of cabinet. Raise and support cover. Remove lock mechanism from cover using nut driver and remove switch and cable from spring tension clips. The last cable stay is zip tie/plug; pry it from hole in cover. Don't worry about saving this cable stay as the new switch has one pre installed. Before lowering cover place an object such as a rolled up towel over the cabinet spring catches to prevent engagement. Then lower cover. Locate two screw on back of control panel and remove with nut driver. Just below control panel on back side of cabinet is a single screw securing a small cover plate. Remove screw and plate. Lift control panel and turn it over. Locate plug for the latch switch and disconnect it. Then set control panel back in place. Raise and support top of washer again and pull faulty switch and cable assembly from washer. Attach new switch assembly to top cover and place cable into spring clip and insert plastic cable stay into hole. Route the connector through the opening the faulty one was pulled from. You may now close the top of the washer. Lift and turn over control panel connect new switch plug and set control panel back in place. Replace screws on back of panel and the small cover and screw. Plug washer power cord in and you should be done.

Parts Used:

-

George E from Lakeland, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

washer would not drain water

need to get washer turned on side where you can work underneath the machine. This job is alot easy if you get where you can see good and have plenty of room to work. You have to unhoook the wire from the old pump and then take the two mounting screws off from there you unhook each hose by squeezing clamp together and sliding backwards away from pump. A pair of needle nose pliers can make this process easier if the clamps are turned in an hard to get to position. You mount the new pump the same way as taking off the damaged pump. Take a screwdriver to help you slide the clamps up onto the new pump makeing sure the sleeves are completely over the new pump fittings and the clamps are slid up evenly, so you want have any leaks. Then replaces wiring harness and mounting screws.

Parts Used:

-

Jacob from Glennville, GA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Pliers

Was this instruction helpful to you?

Thank you for voting!

replaced leaking pump

Easy repair. Went to You Tube and saw PartSelect video. The best instructions...should make a link from parts page to video of install. Also replaced Heat element on Dryer. Watched video first.

Parts Used:

-

richard from asheville, NC

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Pliers

Was this instruction helpful to you?

Thank you for voting!

did not work

-

JESUS from PORT ARTHUR, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

water leak at pump, crack in pump housing

First off always remember to empty all pockets, coins etc ruin pumps.shut off water supply, unhooked water lines and drain into pan.tilted machine forward so i could work on pump which is located lower left. drain pan under pump area, removed 2 rubber water hose's 3 5/16 screws with nut driver. Very carefully un clip rear of housing and removed wire harness. installed new pump

Parts Used:

-

Janelle from Gray, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers

Was this instruction helpful to you?

Thank you for voting!

UL flashes, will not spin, really loud,& black spots under washer

We ordered the outer tub & bearing and now the washer works like it was brand new.

Parts Used:

-

Elijah from Point Hope, AK

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Socket set, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!