SWS1233HQ1 Westinghouse Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

broken belt

I took off the front panel of the washer and placed the belt on the large tub wheel and then the smaller wheel. I placed the belt over the adjustable third wheel and turned the tub in order to get the belt all the way in the grooves. Thirty minutes max to replace. Thanks, my order was 100% satisfactory

Parts Used:

-

odell from Elizabethtown, KY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

belt broke

i left my washer on its back till my belt came in and when it did all i had to do is slip the front off and go at it. it was really fast. then i put the front back on screwed in two screws and hooked up hoses and started washing everything went smooth till i was about to wash wash-n-wear and was like where is my other houseshoe and i remember my dog was bugging me while fixing my washer and dropped my house shoe and i already closed up front soi had to unhook everything and get that out, did not want it to catch on that belt i just bought and fixed lol thanks kristal cumpton

Parts Used:

-

kristal from caruthersville, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking water from machine

-

Martinus from Fort Lauderdale, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set, Wrench set

10 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

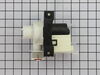

Inlet valve leaked water from supply line(s) back into washer.

Pulled washer electrical plug from receptacle.

Unscrewed hot and cold water inlet hose connectors.

Removed screws retaining backplate.

Removed back plate.

Removed two screws connecting valve assembly to frame.

Pulled two spade electrical wire connectors from valve assembly.

Opened hose clip securing hose on outlet side of valve assembly, using pliers.

Pulled hose from valve assembly.

Valve assembly now free.

Reversed above with replacement valve assembly.

Unscrewed hot and cold water inlet hose connectors.

Removed screws retaining backplate.

Removed back plate.

Removed two screws connecting valve assembly to frame.

Pulled two spade electrical wire connectors from valve assembly.

Opened hose clip securing hose on outlet side of valve assembly, using pliers.

Pulled hose from valve assembly.

Valve assembly now free.

Reversed above with replacement valve assembly.

Parts Used:

-

John from Powhatan, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Belt not tight

Tensioner (pulley spring) replacement.

The whole tub and motor are suspended by springs so I just got a flat bar and using the edge of the bottom of the washer as a fulcrum, lifted the whole thing enough to be able to shove a 2x4 under there at the base of the dome. It was still tight getting the lock washer off the bottom of the spring axel, but it popped off by pushing the ends with two screwdrivers.

The whole tub and motor are suspended by springs so I just got a flat bar and using the edge of the bottom of the washer as a fulcrum, lifted the whole thing enough to be able to shove a 2x4 under there at the base of the dome. It was still tight getting the lock washer off the bottom of the spring axel, but it popped off by pushing the ends with two screwdrivers.

Parts Used:

-

Richard from Rahway, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

5 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer tub stopped spinning and was real noisy

I read the last three peoples experiences when I ordered the part on your on line page. I had already made all the wrong mistakes taking the machine apart, and couldn't beleive how simplified it was on your web site. I had called a local repair shop only to be advised the part would take 4 days shipping and the price of it plus shipping was twice what I paid you. Your part arrived the day after I ordered it on line, Thanks again for being there!!!!!

Parts Used:

-

Raymond from Brewster, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Belt

Very easy to install. Unscrew 2 screws and I was done in minutes. Thanks for the fast part delivery!

Parts Used:

-

Stephen from Honesdale, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noisy operation - "Chugged" during operation.

With prep work mentioned below and a good flashlight it takes about 15 to 30 minutes if you're a good handy-man. If you're not, get a neighbor or friend who is. This repair isn't rocket science, but does take a some mechanical aptitude. This unit is a washer/dryer combo unit. Unplug power cord and remove water supply hoses, the drain hose and dryer vent if required to obtain easy access to front panel. There is water in all the lines, so have some towels and a small gallon bucket to help drain the lines if disconnected. Remove two screws on bottom of front panel. Be sure there is about 2 inches from washer/dryer to floor in front to allow front panel to drop directly down, then pull panel out lightly. Wood spacers or similar are recommended under front feet to prop-up front of washer. (There are two tabs on each side of the front panel. The panel must be pulled straight down to clear tabs). Another option is tilt back the washer/dryer about 60 to 75 degrees unit to make the front panel more accessible if all is disconnected in back and you have the room to do so. Once the front panel srews are removed, you may have to place an object (thin pry bar or screw driver) between the top of the washer unit and the front panel for release (be careful not to dent or scratch the top metal or front panel. Remove front panel and set aside. Locate belt near bottom and tensioner pulley (it moves back and forth laterally), push in tensioner pulley to relieve pressure on belt and remove belt from small pully wheel at motor, then the large drum pulley wheel. Place new belt on large pulley first, then small pulley. Push in tensioner pulley and move middle of belt to the inside of the tension pulley to take up the slack. This process is somewhat hard. It takes good hand strength. Be sure the belt is aligned in pulley grooves. Place washer/dryer back in level position, re-attach water supply hoses, drain hose, dryer vent line and power cord, if removed for repair. Check for leaks in water supply lines and be certain the drain hose is well attached to the drain pipe. (This is a good time to clean or replace the dryer vent line to prevent possible lint fires.) Plug in washer/dryer unit and test as if washing a small load. Re-install front panel after successful test in run operation. The part came quickly and fit perfectly.

Parts Used:

-

Peter from Lynnwood, WA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

5 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Pump motor made humming noise and wouldn't drain water from tub.

Disconnect power. Disconnect water hoses. Remove back panel. Remove top panel. Disconnect bladder ring. Disconnect control panel wire harness and control panel. Remove front panel. Disconnect hose clamps to drain hose and tub drain hose. Disconnect pump motor power supply wire. Disconnect pump screws. Now do everything in reverse replacing old pump with new.. One special note: replace factory hose clamps with new hose clamps.

Parts Used:

-

Matthew from Oakford, IL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking through the main tub seal

-Remove front panel - 2 screws

-Remove the top panel - 2 screws

-Disconnect the lid switch from the top panel - 2 screws

-Remove the agitator cap - unscrew

-Remove the agitator - This was a bit difficult and required a lot of jiggling but it eventually came off

-Remove the inner drum - 5 bolts at the bottom

-Remove the drum mount - 2 bolts and then it got really difficult. A lot of penetrating blaster, wire brushing, jiggling, and some strategically placed hammer taps (don't damage the threads.

-Remove the seal

-Clean up the inner and outer seal seating surfaces

-Rinse and repeat in reverse (pun intended)

-Remove the top panel - 2 screws

-Disconnect the lid switch from the top panel - 2 screws

-Remove the agitator cap - unscrew

-Remove the agitator - This was a bit difficult and required a lot of jiggling but it eventually came off

-Remove the inner drum - 5 bolts at the bottom

-Remove the drum mount - 2 bolts and then it got really difficult. A lot of penetrating blaster, wire brushing, jiggling, and some strategically placed hammer taps (don't damage the threads.

-Remove the seal

-Clean up the inner and outer seal seating surfaces

-Rinse and repeat in reverse (pun intended)

Parts Used:

-

Rob from DACULA, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking hoses

I made my job difficult by removing the back panel, then the side, and finally discovered the front panel opens giving access to the washer. Using heavy pliers I removed the spring clamps and replaced the pump to washer hose and the other hose end to the tub. Turned on the washer no leak only to discover the drain hose had developed a leak. So I ordered the second hose. I was not sure how to release the plastic retaining clamps. Finally just yanked them loose, which worked. Ran the hose through the machine out the back into the drain pipe. I was able to reattach the retaining clamps put the spring clamp on the pump end of the hose. The difficult part was getting the back, sides and front of the washing machine together that took hours.

Parts Used:

-

Dixie from STRANG, OK

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leveling Leg Broken

The leveling legs on my Frigidaire stackable washer & dryer were broken. They are made of plastic and while moving the unit one of the legs had broke off. I ordered two replacements from PartSelect and received them within a few days. The old legs were removed by screwing them out and then the new ones were installed. Pretty easy installation for DIY. The new legs work great.

Parts Used:

-

Brian from Rochester, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer tub was not spinning

Smelled burning rubber, checked belt. Belt was cracked and worn out. Easy repair. Removed front of the machine held together with two screws at the bottom of the unit. Removed top cover of machine (the part with the lid). It just pops off. Pushed tensioner wheel in and took off old belt. Putting new belt on was super easy. Working like a champ now. $20 total with shipping. Not too bad to save a washing machine.

Parts Used:

-

josef from Nashville, TN

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

over filling

no problemO top loader. open top, disco two electrical plugs and a small hose, then remove two screws that hold valve in place and remove. Re install in reverse order. Thanks for your support Eliot in Alaska!

Parts Used:

-

eliot from fairbanks, AK

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

drive belt old and stretched

unplugged machine. pried up with large regular screwdiver on top washer lid. removed two phillips screws bottom of front panel, had to use rubber mallet to drive front panel down to remove as was rusty and old. removed old belt using screwdriver. put new belt under tub pulley and put belt on small pulleys. kept moving tub and springs by pushing on tub. Took several tries to get new belt to go on the large tub pulley but finally did it. I used the instructions you gave for replacing broken drive belt and it worked. replaced front panel and two phillips screws, put top back on and away it went.

Parts Used:

-

George from Sault Ste. Marie, MI

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!