Parts That Fix Maytag Washer Dryer Combo MLE2000AYW Will not drain

Will not drain is a commonly reported symptom for the MLE2000AYW Maytag Washer Dryer Combo, and we have put together a full guide on how to fix this. This advice is based on feedback from people who own this exact appliance. We have listed the most common parts for your MLE2000AYW Maytag Washer Dryer Combo that will fix Will not drain. We have included repair instructions, and helpful step-by-step video tutorials. If you are experiencing this issue, not to worry, DIYers just like you have fixed this, and shared their experience to help you!

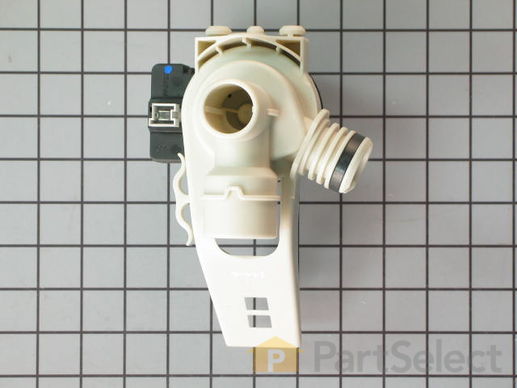

This pump helps expel water from the washing machine and is activated after the spin speed is maintained for a specific period of time.

Replacing your Maytag Washer Drain Pump - 120V 60Hz

Customer Repair Stories

Broken Pump

-

Drake from Crofton, MD

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

Old Pump Stopped Draining The Machine- Impeller In Pump Wore Out

-

Deborah from Westfield, MA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

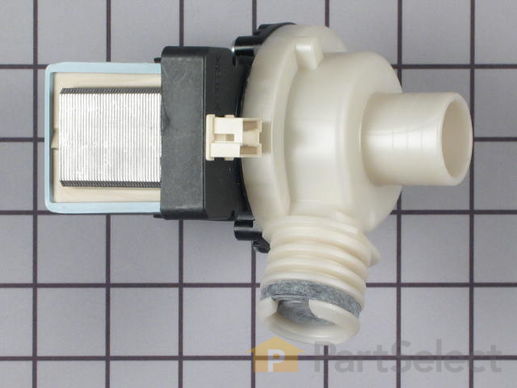

This remote style pump and motor assembly with check valve is used for some washing machines. The motor attached to this pump carries 120 volts and 60 hertz.

Replacing your Maytag Washer Remote Style Pump with Motor - 120V 80W

Customer Repair Stories

change stuck in drain pump, damaged the motor

-

gordon from indianapolis, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

Washer not draining

Drain washer by removing the one screw holding the hose on the bottom rear of the washer, drop the hose to the floor and let it drain (you may want to take washer outside)

Remove four screws holding rear panel

Locate the pump and disconnect the two wires. Wires can be ... Read more attached to either terminal when reinstalling, orientation is not important.

Using 5/16 driver, loosen the hose clamps on the inlet and outlet pump hoses then remove hoses from pump.

Twist the pump counter clockwise then pull straight up to remove.

-

Timothy from Bremerton, WA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

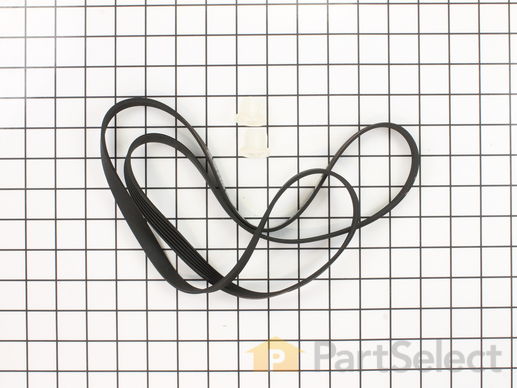

This kit contains a flat drive belt, two motor isolators, and an instructions sheet. The drive belt is made to slip on the pulley until the basket gets up the desired speed.

Replacing your Maytag Washer Drive Belt and Motor Isolator Kit

Customer Repair Stories

Drive belt sqeaked and contiued to roll off the drum.

-

Douglas from Marion, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Belt wore off and broke

-

DANIEL from WEST CHESTER, PA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Wrench (Adjustable)

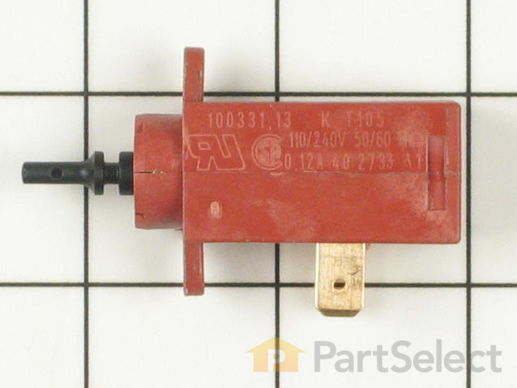

This wax motor is just over two inches long. It is used on some older style washing machines.

Customer Repair Stories

Spin action failed because the door did not lock

-

Michael from Austin, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Wrench (Adjustable)

Door lock light and spin cycle wouldn't work. The tub would drain but left clothes wet.

-

Janice M from Omak, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers