GLET1142FS0 Frigidaire Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

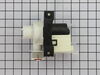

Tub wouldn't drain

First I removed the front panel,then set the timer to run. It began the drain,spin cycle, pump ran, but no water went out. Shop-vac the water out,removed hoses from pump,took out mounting screws from base, unplug pump plug. check hoses for debris since they're open, the impeller was broken. ordered the part . Mount the pump to the base, put the hoses on, plug in motor and replace front panel. plug into wall

Parts Used:

-

Brian from Murfreesboro, TN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

19 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Final Spin Burning Smell

Removed 2 screws at bottom of the front panel - removed front panel by sliding the panel down about 1/2 inch and then away from the appliance- v belt is removed by pushing the tensioner pulley to remove tension from the belt and turning the pulley untill the belt is removed instalation is a simple reverse of the process. I did't have a repair manual so every step was trial and error untill I was able to complete the repair.

Parts Used:

-

NELSON from MAYWOOD, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench (Adjustable)

17 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water Flooded Floor

First I took sides off the washer. I then took screws out of the Drain pump holder. Unclamped the two pipes from it. Undid the wires to then drain pump. Screw in the new pump hardware. Plugged in the wires on side of the pump. Reclamped the pipes. Put sides back on washer and it worked. That easy and took less then 30 minutes. I am no handy man so thats how easty it was.

Parts Used:

-

Matthew from Weyers Cave, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

18 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Belt

I read the others repair story and it was a easy repair, my wife had a repairman come out and check it already, he stated to her that it was a major repair and that he needed to take it to the shop for repair, well he was full of sh##!!! The unit is a stackable washer dryer,if the screws inside the drum backout, the belt comes off and caused mine to brake the belt,my wife found the 2 small screws in the bottom of the tub,theres a small cover on the back that you remove and you can see belt drive pully! Follow the directions that have been explained on others listed it"s easy!!! Mike

Parts Used:

-

mike from perry, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

17 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burning smell, lots of hi-pitched squeaking

I got online and figured out exactly how to take off the front of the washer and then how to replace the belt. It was so easy. The part itself arrived much sooner than predicted. It fit perfectly and my washing machine is now running smoothly and quietly.

Parts Used:

-

Heather from Stephenville, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

17 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Stopped agitating versus level washer feet/leg

My washing machine stopped agitating and spinning and I couldn't afford a repair man...plus I wanted to exhaust any obvious problems first. One of the leveler feet had broken years ago. Since I luckily had determined via reading other posts that the agitator won't work if the cycle safety switch is not functioning right, I thought the safety switch might need to be changed but after careful thought, I decided to order a new levelling leg first because maybe the broken levelling leg was shaking the safety switch so it wasn't connecting right. Once I received the leg overnight, I flipped the washer on its side and had to drill out the old leg. It was a little tricky because of how it broke, but the drill worked. I flipped the washer back up, leveled it with the new foot, and the agitator was miraculously working again...just like new. I didn't need the safety switch. Thanks to partselect.com for having the details of my washer parts to study up on and get me the right part so quickly. I saved myself alot of money.

Parts Used:

-

Sandra from Denton, TX

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

17 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor was overheating and kickins off during the cycle

After turning the water off and removing the hoses,I pulled the top off by removing the 2 screws from the clips in the back and popping the 2 spring clips in the front. I then removed the 2 side screws left and right to allow room for the sides to move out of the way of the motor. The back panel is spot welded so the panels stayed connected. I then removed the 2 screws from the water overflow guard on the motor. Once removed I unplugged the wire harness from the motor. After that the 4 nuts were taken off of the bottom of the motor. I pushed the belt tensioner in and pulled the motor out. Install the motor making sure the nuts are tight as they can work loose from vibration.

Parts Used:

-

Helen from Madison, OH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

18 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drum making thumping noises, clothes getting caught behind drum.

I've always been a "do it yourselfer". If I can fix it, I save money. I took the dryer apart by lifting the top up like car hood. Then I removed the front panel. The front drum glide snapped into place easily where the other one had broken off. The felt strip that you sent was much shorter than the one on the dryer, so once I used the wire wheel to remove the old glue, I cut off the section of the felt that was bad and replaced it with the new felt. The turns much quieter and clothing doesnt get caught behind the drum anymore.

Parts Used:

-

Gerald from Baltimore, MD

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

15 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer machine would fill up with water and not spin and drain

Happened to slam the lid by mistake and the washer started spinning. Recognized the lid lock was working haphazzardly. Also, there was a burning type odor coming from the switch. So I lifted the lid top and disconnected the switch from the lid by unscrewing 2 screws and 4 wires. When I received the new switch, I reinstalled it with 2 screws and reconnected the 4 wires.

Parts Used:

-

MARC from MANALAPAN, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

18 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not start. When turning on, I could hear faint humming, but the motor would not start.

1) Unplug the unit.

2) Remove all screws from top of the unit except for the one in the center front that does not go through the outer casing.

3) Find the Thermal Limiter which is on the back wall near the top on the left side when looking from the front.

4) Disconnect the two wires

5) Remove the two screws that mount the limiter to the back wall.

6) Use an ohmeter to test if a current flows through the unit. If no current flows through (an open switch), then the unit will need to be replaced.

7) Clean any lint that you can at this point.

8) Use two screws to mount new Thermal Limiter

9) Reconnect the two wires to the Limiter.

10) Attach the top of the dryer case.

2) Remove all screws from top of the unit except for the one in the center front that does not go through the outer casing.

3) Find the Thermal Limiter which is on the back wall near the top on the left side when looking from the front.

4) Disconnect the two wires

5) Remove the two screws that mount the limiter to the back wall.

6) Use an ohmeter to test if a current flows through the unit. If no current flows through (an open switch), then the unit will need to be replaced.

7) Clean any lint that you can at this point.

8) Use two screws to mount new Thermal Limiter

9) Reconnect the two wires to the Limiter.

10) Attach the top of the dryer case.

Parts Used:

-

Mark from Normalville, PA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

15 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not start.

Unplugged the dryer from electrical socket. Vacuumed lint from dryer and exit hose. Removed top from dryer. Used pliers to remove the 2 wires from the thermal limiter. Used screwdriver to remove 2 screws that held the limiter in place.

Installed the new limiter, connected the 2 wires, plugged in the dryer's electrical connection, turned on dryer, and resumed my "washday chores".

Installed the new limiter, connected the 2 wires, plugged in the dryer's electrical connection, turned on dryer, and resumed my "washday chores".

Parts Used:

-

Onmi from Douglas, GA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

15 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer Drum Squealing Loudly!

This unit is a stackable washer&dryer,so first pull unit away from wall atleast 4 foot. Unplug power cord,then take10 dagree front panel off then the control panel off and unplug the 5 connetors if your unit has that many,then lay panel asside. Take dryer door off,makes it easier when putting it all back together. Now take front panel off and the dryer lent tube,now just take the 3 center phillips head screws out and slide drum out. Pull upward on what they call the shaft which held drum on. Now these are the parts you should order. Belt,grounding ball clip,grounding ball,drum support bearing,bearing bracket,and most important part is the shaft. The shaft is ur insurance for the whole job. Use a good grease like white lithium grease and coat the shaft end and the drum support bearing. The grease will cut down on friction for a while,and re assemble the way you took apart. Reminder grounding ball goes behind drum support bearing not in front. Good luck and please vaccum.

Parts Used:

-

john from waynesboro, VA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

13 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The knob had become unable to turn on the dryer

After waiting for a repair man to deliever the part over 1 month I finally went on line and ordered thru your company and the part was here in less then 3 days. It took about 5 second to if that long and the dryer is working well. Now all I have to do is get a refund fromn the repair man.

Parts Used:

-

Jerome from Aberdeen, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

13 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer wouldn't heat

First: Remove front and top cover

Second: remove electrical cover assbly

Third: motor belt removed

Fourth: drum assbly and bearing shaft and bracket bearing replaced

Now I need urgently (already ordered) the thermostat and glide drum

Second: remove electrical cover assbly

Third: motor belt removed

Fourth: drum assbly and bearing shaft and bracket bearing replaced

Now I need urgently (already ordered) the thermostat and glide drum

Parts Used:

-

Ivan from Guaynabo, Puerto Rico, AL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

36 of 58 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the pump had died

First I removed the two screws that hold the pump in place. I then pulled the pump out and replaced it with the new pump.

Parts Used:

-

loudvik from glendale, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

15 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!