DLGX3002R (ACREEUS) LG Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

igniter would not light

Initially replaced igniter. Didn't think it was bad though. Read other suggestions on another website. None were the correct diagnosis for my situation. And when I figured it out they did not offer correct part. The dryer thermistor temp sensor (probe sensor) is what I replaced. Found it on Parts Select. I did replace other parts also. But that's the one that ultimately was the issue.

Was not hard at all if one is even a little handy.

Was not hard at all if one is even a little handy.

Parts Used:

-

Dave from SAINT JOHN, IN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

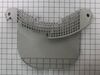

The lint screen had a broken edge

The lint screen that this company sent was 3x too large. I called to return/exchange it. No one available - go to customer service.

I went to customer service and entered my email address and the order number (while I was looking at the original order1). The email and order number could not be found.

I am still waiting to hear from someone from the company to get a RMA and return label! Will NEVER use this company again.

Vivien Joebchen

I went to customer service and entered my email address and the order number (while I was looking at the original order1). The email and order number could not be found.

I am still waiting to hear from someone from the company to get a RMA and return label! Will NEVER use this company again.

Vivien Joebchen

Parts Used:

-

Vivien from CARLSBAD, CA

-

Difficulty Level:Very Difficult

-

Total Repair Time:Less than 15 mins

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

1 of 4 Drum Rollers Froze Preventing drum rotation.

Replaced idle pulley wheel, worn drum belt and all 4 rollers (1 frozen) due to dryer age. Site video re general disassembly/re-assembly easily adapted to this model and very helpful with exception of replacement of drum rollers. New rollers received (AGM75510755) were pre-mounted on included shafts. This required removal of existing roller shafts to replace with new shaft/roller units. Site video shows placing a new roller on existing shafts after removing a plastic retaining clip. New roller/shaft assembly is a better option and fortunately I did not order extra retainer clips! Rear drum roller shafts have small carved out space to fit a box end wrench to remove shaft nut. Watch out for sharp edges on internal steel parts!

Parts Used:

-

Mark from OSHKOSH, WI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

I would turn on the dryer it would run for about 10-20 seconds and then shutoff, and could smell something burning

-

Kevin from MASHPEE, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Not heat

Followed the instruction on video.was great after three parts now is OK .we have heat.still cheaper than having it service.

Parts Used:

-

Sal from MORENO VALLEY, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer was making a terrible sound.

An appliance repairman determined the problem which was that it needed new pulleys and thankfully PartSelect carried them. He installed them in an hour and my dryer runs fine now.

Parts Used:

-

NANCY from ATASCADERO, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Igniter burned out

Completely had to dismantle the dryer to get to the igniter.

The screw holding the igniter is a SOB to get at for extraction, and even worse putting back.,

The screw holding the igniter is a SOB to get at for extraction, and even worse putting back.,

Parts Used:

-

EDWARD from KNG OF PRUSSA, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lamp cover broke

Unscrew the screw, remove old part, place in new part, replace screw and you are done.

Parts Used:

-

Lorraine from SEQUIM, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drum wasn't turning

I took the dryer apart. You have to take the top off, then the door/front off. There are wires & other parts that need to be unhooked as well. A flat tip screw driver can be used to pop the top off. The screws were all phillips. Once you take that all apart, then you can access the drum. I bought the belt because I thought that was what was wrong with it. Turned out to be hair in the drum rollers. Took those all off & put wheel grease on each of them, put new belt on (since I had it LOL) then put it all back together. Make sure everything is lined up correctly otherwise you will have to take it apart & reline (which I had to do)

I am a 49yr old female & was able to do this repair on my own!

I am a 49yr old female & was able to do this repair on my own!

Parts Used:

-

Beth from FROST, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no heat

I replaced the thermistor, then the gas ignitor which were easy to get to once the drum was out. The gas is still not igniting so not sure where to go from here. Putting the drum belt back on took some muscle. But then I'm 71.

Parts Used:

-

Barbara from CUDAHY, WI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Thumping noise when on

-

Bob from Holiday, FL

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Light bulb in dryer burndt

-

Duane from TROY, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

4 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cracked lint filter

-

Richard from MADISON, AL

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drum bearing had gone bad causing excessive noise

Followed the repair video provided in the order confirmation email. Was easy.

Parts Used:

-

Dennis from Manchester, IA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

HST code given by dryer

Called LG on the phone and they gave the button presses for diagnostics, which then gave the HST code, saying the Humidity sensor was bad.

The part was described as the Humidity sensor module. Actually it's just the wire leads for the sensor which must be electronic and only accessible by disassembling the dryer. There were descriptions about cleaning the wires, perhaps because some people use dryer sheets which cause a buildup on the wires and prevent them from doing their job. I use wool balls and have no buildup on my wires and replacing them did not fix the sensor, because the module accessible inside the dryer is not the moisture sensor, but only the wire leads.

The part was described as the Humidity sensor module. Actually it's just the wire leads for the sensor which must be electronic and only accessible by disassembling the dryer. There were descriptions about cleaning the wires, perhaps because some people use dryer sheets which cause a buildup on the wires and prevent them from doing their job. I use wool balls and have no buildup on my wires and replacing them did not fix the sensor, because the module accessible inside the dryer is not the moisture sensor, but only the wire leads.

Parts Used:

-

marty from NEOSHO, MO

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!