DLE2 Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

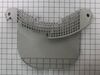

Former lint trap would catch clothes in dryer and rope them together

-

Brian from LOCKPORT, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

11 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noisy when drying. A bumping noise

Watched the video a couple of times. After that it was a breeze.

Parts Used:

-

Arthur from SOUTHLAKE, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set, Wrench set

11 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lint filter and cover guide melted which was ripping up some clothes

Just unscrewed four screws. One piece stays behind which is a sensor then pull up on it, put it back in the same way, put the four screws back in and it was done.

Parts Used:

-

Kevin from FARMINGVILLE, NY

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

14 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would turn on but no heat to dry clothing

Unplugged dryer, pled forward to get access to back of dryer. Removed screws, enabling top, front control clip. door panel to be taken off. Lift out drum, replace heater assembly. drum belt, thermistor. Cleaned entire interior and reassembled, working good as new. All parts fit and were a exact match.

Parts Used:

-

Spencer from SHALIMAR, FL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

11 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Klunking noise and poor drying

The top was hard to figure out but I found that it pops off at the front with a flat screw driver. Be careful not to scratch the paint. I found that a rear drum roller was bad and the drum seals were deteriorated. I ordered a new belt, roller kit, front, and rear seals. This way I hoped I will not have to take it apart again. The seal were the hardest parts to replace. Make sure you look and remember how they were on before removing them. The directions were not to clear on the seals. The rest were good. It is much better to do it once. Take a picture if possible, it might come in handy as I took mine apart a week or so before the parts came in. I also cleaned out all of the accumulated lint buildup with a shop-vac, including the vent pipe, heater area, and front door. When I was done with this it worked like brand new.

Parts Used:

-

Harry from Atco, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench set

10 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

LG dryer making loud noise (older model)

I followed a Repair Clinic Urube video except the video had a model with the controls in front and my dryer has the controls on a back panel. The difference was in how to get the top of the dryer off after removing all the screws. The video

said to push back on the top panel which did not work because of the back controls. Instead I had to push up on the front to release it and then push back. The rollers were also in a slightly different place but were easily found and replaced. The dryer is now back to normal.

said to push back on the top panel which did not work because of the back controls. Instead I had to push up on the front to release it and then push back. The rollers were also in a slightly different place but were easily found and replaced. The dryer is now back to normal.

Parts Used:

-

Darline from DREXEL, MO

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

10 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Maytag Performa squeaking loudly when running.

My wife's dryer started squeaking very high pitched, intermittently and then continuously when running. It progressed to a loud shrieking, unbearable throughout the house. Make sure you unplug the dryer. First I replaced the Drum glide and cushion kit. This was easy to do. Pry open the top of the dryer open with a screwdrive or putty knife. Now reach in and remove the retaining screws holding the front panel against the side panels. After releasing the front panel, let it fall forward about 4 inches and then unplug the two wire connected to the door closed sensor. Now carefully slide the thin belt towards the back of the dryer, it will release eventually as it is pulled off the pulley (dont worry, getting it back on is not that hard). Now you can remove the drum. After removing the drum, there are two tan or bluse plastic drum glides that the fron of the drum rests on. They can be worn out along with the cushion beneath them. Replace them with new one. This actually did NOT fix the problem. I put everything back together and....SQUEAK!! Next I undid everything as before and removed the drum. Now I decided to lubricate the rear rollers. First I used a silicone lubricant that again did not fix the problem. I could not find hi-temp lubricant, so I decided to use Axle grease. Bingo...no more squeak. To lubricate the rollers, remove the retaining clip and pull the wheel off. I put an even thin coat on the post they rest on and the inside hole of the wheel. Replace them and remember to put the retaining clip back on. Now replace the belt onto the metal pulley first, with the threaded side of the belt down towards the drive shaft, it should loop around the drive shaft and then you can pull it around the drum, slowly feedingthe drum farther and pulling the belt back along the drom. The smooth side of the belt should be on top of the drum. Now you have to reach back under the drum on the bottom right corner below the lint trap and pull the belt over the tensioner. Sounds harder than it is. Volia...that should fix it. Its been 3 days of non-stop laundry since the repair and no squeak. Next time I will purchase the replacement roller package, but this worked for now. Good luck.

Parts Used:

-

Jason from Temecula, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No heat from element

Removed the top cover, unplugged the wires on the element, removed bolt holding the element in place. Replacement took about Fifteen minutes to complete.

Parts Used:

-

Jason from Waukesha, WI

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

12 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Heating element failure

After disconnecting power, I popped the lid open by grabbing it on the front sides. Swinging the lid completely back and out of the way, I disconnected the wires from the thermostat. Removing a few screws, the thermostat and the heating element were removed. Reverse the steps and that's it. Very easy repair and now the dryer is like new. While opened, I did take advantage and cleaned all of the lint from the exhaust passages.

Parts Used:

-

Melissa from Lawrenceville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

9 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Heat to my Dryer

1. Had to find out what was causing the problem by eliminating each part one by one using a multimeter. I got a video link from parts select on how to do this.

2. Then got another video link sent to me by parts select on how to take my dryer a part and replace the part.

3. Followed it step by step and it worked really well.

4. The process was great except shipping was excessively high for such a small part.

2. Then got another video link sent to me by parts select on how to take my dryer a part and replace the part.

3. Followed it step by step and it worked really well.

4. The process was great except shipping was excessively high for such a small part.

Parts Used:

-

James from ELLENVILLE, NY

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

extremely noisy operation

unplugged unit, opened lid, removed 2 screws & door switch from front panel, removed front panel & drum.

Removed clips & washers from rear roller shafts, removed 2 screws (each) attaching rear roller shafts to rear of unit. Replaced rear roller shafts, thrust washers, rollers & clips. Removed clip from belt tensioner idler arm, replaced idler pulley wheel & clip.

pulled tensioner toward motor side and locked in place with broomstick. Placed new belt over drum & installed drum/belt into unit, engaging rear drum lip over new rear drum support rollers. Guided belt

over motor shaft and slowly released broomstick to

tension belt. Turned drum by hand to ckeck belt tracking. Reinstalled front panel & door switch, installed 2 screws holding front panel to case. Closed lid. Plugged unit in & tested for proper operation-OK.

Removed clips & washers from rear roller shafts, removed 2 screws (each) attaching rear roller shafts to rear of unit. Replaced rear roller shafts, thrust washers, rollers & clips. Removed clip from belt tensioner idler arm, replaced idler pulley wheel & clip.

pulled tensioner toward motor side and locked in place with broomstick. Placed new belt over drum & installed drum/belt into unit, engaging rear drum lip over new rear drum support rollers. Guided belt

over motor shaft and slowly released broomstick to

tension belt. Turned drum by hand to ckeck belt tracking. Reinstalled front panel & door switch, installed 2 screws holding front panel to case. Closed lid. Plugged unit in & tested for proper operation-OK.

Parts Used:

-

Paul from Daly City, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer belt broke- drum would not turn

This was so much easier than I though it was going to be. Pulled up on the top part of the dryer and folded it over to the back. Removed 2 screws for the front panel and disconnected some wires. Laying down I fed the new belt on and made sure the tensioner was put back into the right spot, because when the belt broke the tensioner sprung to the other end of its travel. Put everything back together. This was made super easy because you guys had the parts and the shipping was super fast. Alot of the local shops in the area didnt even carry the belt or were not helpful..

Parts Used:

-

Ronald from Oakdale, CT

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud screeching metal to metal sound. The roller and "axle" were worn out.

First I disconnected the power cord. Next the top of the dryer was easily popped upen with a screw driver by inserting it between the top panel and the front door panel. I removed the two sheet metal screws that held the door panel on the upper right and left sides. The door panel was easily lifted up and out and set it to the side (the door switch can stay connected, the wire is long enough). d I pulled the drum out from off of the rollers that hold the drum in place. No need to remove the belt, it stays in place. I reached through the drum and removed the two hex-head screws that held the roller in place ( I only replaced the left one) and added the new one. I pushed the drum back in place over the rollers (it snaps in place). I propped the drum up with a short screw driver to raise it off of the right and left drum glides (on the bottom). I replaced the felt pads and the plastic glides and set the drum back in place. I also replaced the felt ring (seal) that circles the door opening that the drum also glides on. I glued it in place in spots (with gasket glue). It folds back over itself and forms a double thick pad. You will see what I mean when you see how the old one looks. I replaced the front door panel and snapped the top panel back in place. I let the dryer set over night so the glue would set up. I turned it on the next morning and it is as quiet now as when it was new. Oh ...Jay (the husband) did the work not Jean the wife (her dryer, her credit card)

Parts Used:

-

JEan from Cypress, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer ran, but did not heat up and dry clothes

Quick note: I saved over thirty dollars using partselect over the actuall Maytag store parts dept and they still had to order the part to be delivered in 4-5 days. First I pryed the top off of clips in front then removed the screws that hold the element into place, removed the therostat bracket held in by one screw and disconnected wire clips (after labeling the wires) and removed the thermostat from bracket by two screws then disconnected the element wires and slid the old element out. Reversed the process to reinstall the new parts.

Parts Used:

-

Matthew from Anthom, AZ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Socket set

8 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer had no heat

I unplugged the dryer and then opened the top by releasing the two clips with a large flathead screwdriver. The heat element tested good with ohm meter but the thermistat was open. Replaced the thermistat and it fixed the problem.

Parts Used:

-

Michael from Temple, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!