DBB3300EA0AA General Electric Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Squeeling noices

Followed written and video on repair.

Parts Used:

-

Ronald from Lawrence, NY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

My dryer squeaked

First I found my dryer on utube and watched the troubleshooting video. I then used your parts manual to find and order my parts. Finally. I used your repair video to install them. My dryer is like new. Piece of cake. Many thanks

Parts Used:

-

Del from Temple, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

dryer door would not stay closed

-

Dave from Redondo Beach, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

Sqeaking during operation

I used these two videos to help me clean the inside of the machine, then change the drive belt.

Parts Used:

-

Pete from San Dimas, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

loud dryer noise

I'm retired on a fixed income and the last thing i needed to do was buy a new dryer. I got on the internet and googled GE Profile dryer and opened Part Select. The trouble code listing with the probable part replacement was very accurate. I was also able to view a video to show me exactly how to make the repair. I ordered the necessary parts and was amazed at the UPS delivery (next day). The cost of the parts was reasonable, fit perfectly, and now my dryer is running like new. The wife is happy, and when she's happy everyone is happy.

Parts Used:

-

JOHN from DAYTON, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

The main symptom was a burning smell that got on the clothes and the dryer was somewhat louder than it had been.

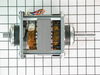

Researching on the web I thought the trouble might be lint buildup or trouble w/ one of the parts involved in spinning the drum. However I cleaned out all the lint and replaced the belt and idler pulley and this didn't improve the smell (drum bearing was fine). I then concluded the trouble was the motor. Running the motor w/o the drum in place confirmed this was where the noise/smell was coming from. Replacing the motor was fiddly--I had to remove the clip holding the motor (pried the top w/ a screwdriver), wires (made a diagram so as to put back in same order, they were hard to get off--a pliers did the job), clamps holding the motor on the duct, the motor mount, the duct, the fan. Putting all this back together took a while (not hard just fiddly). Tested the motor w/out the drum in place and it sounded fine. Put the drum and back/front/top panels back and the dryer runs fine now. All parts came quickly and exactly matched the parts in my 1993 Hotpoint dryer. As others have said the pulley kit is not needed--these are included w/ the motor. BTW I am a 53-year-old lady. Thanks to all who took the time to write up their experiences--big help!!

Parts Used:

-

Kristin from Bellevue, WA

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Squeaky Dryer

We had to remove the top of the dryer in order to open the front panel. The bearing was located on the front panel and was relatively easy to replace. No more squeaking!

Parts Used:

-

Lynda from The Woodlands, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer making squeaking noise.

Viewed a couple of videos on how to DIY, which were extremely helpful, so be sure you look at one of these videos before tackling this problem. I then followed the instructions in the videos, I did not have any issues, repair was quick, smooth and successful. The squeaking dryer is usually caused by a bad drum bearing and/or worn drum slides, which were the reasons for my noisy dryer. I searched for the recommended repair parts detailed in the videos, which included the front drum bearing, the green and white slides, and threw in the lint filter replacement as one of those 'might as well replace this part while I'm at it' items. Caution, the replacement slides do not come with the front drum bearing, so to be safe, order the needed two each white and green slides when ordering the drum bearing. First, be sure to UNPLUG the dryer. There are only 4 screws to remove, two that hold the top panel, which are accessed from the inside top of the dryer door panel once he door is opened, and the two that hold the front door panel to the cabinet, which are accessible from the inside of the cabinet once the top panel is removed. When removing the door, gently lift up on the dryer drum. Be careful removing the door to ensure you do not pull the wires loose from the door on/off control switch, my door is a left hand open/close installation, so the switch is located on the left side. The door must be removed because the drum bearing is attached to the top of the dryer door. You can unplug these wires to be safe, just remember to reconnect the wires to their appropriate terminals. The drum bearing simply snaps out and the new bearing snaps in. The slides attach to the drum bearing, so be sure to attach the new slides to the drum bearing before replacement. I also cleaned out the vent channel once I removed the old bearing because the drum bearing attaches to the top of the vent channel assembly, might as well ensure there is no lint blocking the channel while you have access. Ensure the felt gasket is in good order and realign if necessary, the felt gasket can also be replaced if needed and available on this site, see diagrams for alignment instructions. Replace the four retaining screws in reverse order, door panel first, replug on/off switch wires if unplugged when removing the door, then reattach the top panel and once completed, plug the dryer power cord back in. Squeak should be a memory. The cost of these parts vary based on where you purchase. One site is extremely more expensive than PartsSelect, both carry OEM replacement parts, so I recommend this site to purchase parts for this, and any future needs for GE applicance replacement parts. This site provides needed detailed information for a homeowner to make repairs including assembly diagrams, videos and homeowners repair stories. A squeaking dryer is irritating but should be resolved quickly to prevent any possible further damage to the drum or other internal parts of your dryer. Hope I've given enough details, if not, be sure to read other's repair stories, view the diagrams and watch the videos on how to resolve this problem. Cheers.

Parts Used:

-

Albert from Hampton, VA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Loud Squealling noise from dryer

Opened the door and removed 2 screws from inside/top of door. Removed top and then removed 2 screws from back of front panel. Lifted drum slightly to remove front panel and attached new slides.

Parts Used:

-

jeffrey from hertford, NC

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer making all kinds of noises

I took the Dryer apart easily just as the instruction video showed. I quickly noticed that I needed what was described as Gray or Green slides as well as the white slides recommended. I had to find them locally and it took an hour to retrieve them from a local repair shop. The Rear Drum Bearing was extremely hard to remove from inside the Drum. The screws had frozen in place. Finally broke them loose with Vise Grips from the back side. All the new parts went in very easy. Highly recommend getting Green Slides and also since it's apart put a new belt on, which I did not do.

Parts Used:

-

Robert from The Hills, TX

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Dryer was making a grinding noise.

My dryer was making a grinding noise so I tore it apart using a screw driver, a torks bit and a pair of pliers. It took about 15min to get it appart. I found the idler pully was worn out and broke in 2 pieces. I ordered the new part along with a new belt, since I had it appart, and they arrived the next day. It took about a half hour to put the new parts in and put the dryer back together. Works great now. While I had it apart I cleaned the elements and greased the bearing.

Parts Used:

-

Walt from Richwood, OH

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

broken post on switch

removed 4 scewws deom case snapped out switch placed the new one attached two wires re attached with the 4 screws

Parts Used:

-

Myron from Blairsville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Loud stretching

My dryer was making a loud stretching sound which I thought, because of previous experience, could be fixed by replacing the bearing slides. The problem turned out to be that the blower wheel that is attached to the motor was loose. I pushed the blower wheel all the way in so that about 1/4" of the motor shaft sticks out. I then tightened the bolt with a socket wrench. Problem solved.

Parts Used:

-

hector from bellerose, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Dryer was making squealing noise.

Watched parts select video. Removed door screws. Pulled door off. Removed top screws. Pulled top off. Disconnected wires. Removed light bulb which broke. Removed drum bearing. Used pliers to remove the remaining part of the broken light. Put in new drum bearing. Installed drum bearing slides. Two are recommended. Put the dryer back together. The noise has stopped.

Parts Used:

-

Anthony from Randallstown, MD

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer squealed when it ran

I watched the video on PartSelect.com on how to change out the Front Drum Bearing and where and how the Drum Bearing Slides were installed and then I got a Phillips Screw Driver and a pair of Needle Nose Pliers. The first thing I did was unplug the dryer. I unscrewed the two screws located at the top corners of the door opening that fastened the top of the dryer and then removed the top and set it aside. While I had the top off I took the opportunity to note the condition of the Drum Belt in case it also needed to be replaced. The drum belt appeared to be in good shape so I removed the two screws that fastened the front of the dryer, pulled the front of the dryer forward letting the drum fall slightly off of the Front Drum Bearing, and then disconnecting the door switch wires making sure I wrote down where each of the three wires attached to the wire harness on the front panel of the dryer went. I pulled the front panel off and the first thing I noticed was that all four of the Drum Bearing Slides were GONE as were the brackets on the Front Drum Bearing that held them. There were a couple piles of grey dust on the front panel which were the remains of a couple of the Drum Bearing Slides. I unscrewed the light bulb and just pulled the Front Drum Bearing off and discarded it. The new Front Drum Bearing snapped easily into place and I installed the Drum Bearing Slides, of which there are TWO types, into their proper brackets. I cleaned out the lint from the exhaust vent on the bottom of the front panel as well as the hardened lint from around the fan on the bottom of the dryer where the exhaust vent on the front panel attached before I plugged the three door switch wires back in their proper locations on the front panel wire harness and, making sure the drum rested on the Front Drum Bearing, reattached the front panel and screwed the fastening screws back into place. Then I reattached the top, which took a few minutes and some colorful metaphors because anyone who has ever done any kind of repair knows that the mechanism you are trying to repair never wants to go back together. After getting the dryer top where it was supposed to go I screwed the fastening screws back into place. Before I plugged the dryer in to test it I took the opportunity to remove and completely clean out the dryer exhaust vent pipe from inside the pipe that comes out of the dryer all the way to where the vent exhausts to the outside. You wouldn't believe how much lint hardens on the insides of the exhaust vent pipe. I reattached everything, plugged in the dryer, and turned it on. The dryer was as quiet as it was when I first bought it.

Parts Used:

-

Mark from Powell, OH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!