CYG1005AWW Magic Chef Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

High limit thermal fuse blew because of lint buildup in discharge vent pipe

Opened things, saw lint buildup, cleaned inside of dryer, then cleaned entire vent discharge system, put new thermal fuse back, turned on dryer and heard metal to metal, opened dryer back up, saw missing glides (both gone). Ordered what I thought were 2 glides, 2 days later 1 showed, called and was told I didn't "update" when I changed order info (parts supplier cautioned to replace 2, should only sell in pairs) so then had to wait again for 2nd glide to show up. Replaced them today and noticed dried clothes are now cooler when finished. Will note in future if clothes are warmer, clean ductwork.

Parts Used:

-

Gary from PORTSMOUTH, OH

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Socket set

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would stop during cycle and then not restart. When I started the dryer, there was a short buzz sound as the motor started.

First I removed the bottom front cover attached with two screws, then the main front cover attached with two screws. I then removed two more screws holding the top in place, detached three wires and raised the top lid. I held the top lid out of the way with a cord tied off to a cabinet above. I then removed four screws holding the front support panel in place and set it to the side with wires still attahced. Then I slid the dryer belt off the drum and removed the drum. Next I removed the cover of the fan wheel by removing several screws. This allowed me to unscrew the fan wheel (reverse threaded) by anchoring the motor shaft with a wrench and using a large socket to turn the nut end of the fan wheel (then was no snap ring). I then popped off the two clamps holding the motor in place and removed the motor. The only tricky part about assembly was putting the belt back on the pulleys once the drum was installed. You can't see the pulleys once the drum is installed so it is done by feel.

Parts Used:

-

Bob from Denver, CO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

6 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No heat...

Removed and replaced both the thermostat sensor and the ignitor. Tested thej dryer and it worked. Replaced the front panel and it was good to go.

Parts Used:

-

Charles from Long Beach, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer would shut off during dry cycle. It was difficult to rotate drum manually

I looked at your on-line diagrams (exploded views) and basically used them as dis-assembly info.

I removed the bottom panel, followed by the front panel, the drum holders and drum.

Toughest part was the spring clips holding the motor in place,,,, but notes on your site from other folks doing the same motor replacement solved that one,,,,,, I used a flat bladed screwdriver and pliers to manipulate the clips both off and on

I removed the bottom panel, followed by the front panel, the drum holders and drum.

Toughest part was the spring clips holding the motor in place,,,, but notes on your site from other folks doing the same motor replacement solved that one,,,,,, I used a flat bladed screwdriver and pliers to manipulate the clips both off and on

Parts Used:

-

Dave from Bend, OR

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Air Duct Damaged

Removed 2 screws from dryer lower front panel and removed panel. Then removed upper front panel (no screws, just clips). Removed screws from existing duct assembly (2 for the duct assembly and 3 that held the top of the assembly to the dryer opening (and the reason for removing the upper front panel). Original part was a two piece assembly, new one is a single part, using less screws. New part is also deeper that original assembly. There was enough room for the extra size. Installed new part, replaced top 3 screws, top panel, and bottom panel. The replacement was very straight forward. Anyone that has done this before could do it in a few minutes but without prior knowledge or a manual, it took a full 1/2 hour to do the replacement.

Parts Used:

-

jEFFREY from Troy, MI

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Female End Of The Door Catch Broke

First I put the square female end iof the door catch kit nto the square hole as snug as I could. Then I gently pushed the door against the piece until I heard it click in to place. That's it!! Sooooo simple--

Parts Used:

-

Tara from North Canton, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud squeking noise as drum turned

I was somewhat intimidated by the fact that dryers are all repaired from the front. Pulling out the drum seemed scary at first, but that turned out to be very easy. After removing the front panel and lint shroud it is easy to reach the idler pulley and take the tension off the belt. If you're going to replace the rollers which is generally the cause of the noise, get new retaining wrings and a decent pair of pliers for them. The rings can lose all their spring easily by strechting them too far to get them off. Replace the idler pulley and belt while you have the dryer apart. Vacuum all the lint out of there and you're good to go.

Parts Used:

-

Thomas from Naugatuck, CT

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeaky belt

Removal of the entire 2 front panels

Removal of the heat exchanger into the drum

Removal and replacement of the belt

Reinstallation of the heat exchanger, and both front panels

Removal of the heat exchanger into the drum

Removal and replacement of the belt

Reinstallation of the heat exchanger, and both front panels

Parts Used:

-

Michael from Marietta, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The dryer door latch was broken.

The replacement part just snapped into place. (The old part had fallen out) It took less than 30 seconds to do the repair.

Parts Used:

-

Jack from Memphis, TN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door would not stay shut

Took off the four screws to get to the female clip and used pliers to squeeze it out. Next was using pliers to pinch out the male connector and place the new one in.

Parts Used:

-

Eli from North Stonongton, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door wasn't staying closed

popped up top of dryer -- With pliers squeezed clips on inside of latch - - with screw driver pryed latch out -- just pused new latch in.......... Thanks to parts select for sending part sooo fast.. wife was happy.. Thanks, Dale

Parts Used:

-

Dale from Livingston, TX

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeaking motor, over heating, thermal switch kicking out.

Unpluged dryer from outlet, disconnected vent, positioned dryer on side, removed screws from bottom panel, pulled pannel away from dryer body to gain access to motor. Disconnected drum belt from motor pulley, disconnected wire harness from motor. Removed motor mounting bracket assembly and placed entire assembly on floor. Removed clamps and blower assembly from old motor, installed new motor and reassembled. Very easy project, hardest part requires some trouble shooting knowledge to determine the exact cause of problem.

Parts Used:

-

Ernest from Ida, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

5 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

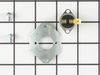

At the end of the drying cycle, the clothes had a bunt smell. I checked the lower compartment of the dryer and found the limit thermostat in two pieces and realized this could be the culprit. I was able to snap them together, but this did not work, therefore a new stat

First I unpluged the dryer, removed the two screws from the bottom access panel. I used a small socket to remove the screws securing the limit stat to the burner chamber, nut driver was too long.

I installed the new limit stat with the two screws and attached the two leads. Plugged in the dryer and conducted a test run, burner ignited. I turned the dryer off and replaced the access panel.

I installed the new limit stat with the two screws and attached the two leads. Plugged in the dryer and conducted a test run, burner ignited. I turned the dryer off and replaced the access panel.

Parts Used:

-

James from Mokena, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Load noise from dryer

Had to figure out how to open the dryer - bottom screws in front and work up, removed the drum and found the fan blade was broken. Had some difficulty removing the fanblade from the motor shaft but after that the new one was easy to install. I did need help to place the belt and drum back into place. as one person has to hold the belts on the pulley while the other adjusts the belt while putting the drum back into place.

Parts Used:

-

Mike from Pacifica, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Socket set, Wrench (Adjustable), Wrench set

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Third round after replacing gas line dryer ran one month then heating element went bad replaced and it overheated these two components.

Removed the top and opened the front cover had to use a 1/4 inch socket with a 5/16 and a short adapter to remove the sensors. The push on wire clips were very hard to remove so I used a pick to open them a little. Before replacing the wires I sqeezed them back to normal so they would not vibrate off. Not much space to work if you don't have the tools but it could be done by removing the gas tube and the heat tube but it will take more time. We have put perhaps 30 loads into the dryer this week and its working better than ever. The Thermostat limit switch was blown used a voltmeter to test for continuity. and I accidentally broke the ends of the high limit switch off while testing due to the tight clips. Maytag sure cant make them like they used to but glad I found a place to get the parts which are easy to replace and the instructions are great to figure out the problem.

Parts Used:

-

Jose from Ridgecrest, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!