ATF8000FS1 Frigidaire Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

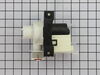

Water Flooded Floor

First I took sides off the washer. I then took screws out of the Drain pump holder. Unclamped the two pipes from it. Undid the wires to then drain pump. Screw in the new pump hardware. Plugged in the wires on side of the pump. Reclamped the pipes. Put sides back on washer and it worked. That easy and took less then 30 minutes. I am no handy man so thats how easty it was.

Parts Used:

-

Matthew from Weyers Cave, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

18 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Every time the washer went to spin it walked accross the room

Once I figured out that the shocks were broken it was very easy to fix. Remove back panel first. Then remove the control box on bottom left corner to gain access to the left shock. Pinch the locking mechanism on the plastic locker bolts and remove the four bolts from both shocks. Replace with new shocks and replace control box and back panel. It probably took more time moving the washer to where I could work on it then it did to fix it. Works like new.

Parts Used:

-

Gerard from Wilson, WY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

15 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer will fill and drain but will not spin or agitate

Went by the percentage of people with same problem- door switch was the highest. Ordered door switch and a new belt (belt was getting worn- 6 yrs. old) Door switch did not fix problem. Saw on website that it could be motor control board. Took motor control board out. Nothing visible wrong with anything. Decided not to spend $$ on new board. Figured new washer would be better. Put motor control board back in and tried it......works like new! Must have been a loose wire on the motor control board. Next time I will check wires first. :) Getting motor control board in and out was time consuming but no too hard.

Parts Used:

-

Gabriel from MERRILL, WI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

16 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Frozen pipe

Removed top cover to get access to intake pipe for hot & cold water. Remove electrical connections and two screws replaced part and cover. Thanks very quick service.

Parts Used:

-

Frank from Auburn, NH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

18 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door lock switch plastic bits broke

The previous posts made it dead easy - remove screws at the back holding top in place; slide top back; remove screws holding door latch assembly; disconnect three plugs, and connect new part. Replace fastenings, done! Throw up hands and wait for the official time;)

Parts Used:

-

Herbert from Amherst, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

15 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The washer wouldn't spin at all.

I unplugged the washer. Then I unscrewed the two screws on the back, top edge of the washer. and lifted the top off. Next I unscrewed the door lock/switch assembly, reached down in the machine from the top and pulled the switch out. As I unplugged each one of the three plugs from the bad part, I plugged them into the corresponding connections of the good part. Then I screwed the switch back into place, replaced the top of the washer and screwed it back on. I set the washer spin and cheered madly when it went into spin mode. The hardest part was actually turning the screws because I'm a small woman and my hand strength is not what it used to be. But really there was nothing difficult about this repair.

Parts Used:

-

Leah from Ramsey, MN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

14 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drained but would not spin

The hardest part was figuring out how to get the lid off. You simply remove two screws from the back of the lid and jerk and slide the lid towards the back of the machine. Take out the screws that hold the front panel on, tilt the front out and access the lock/switch assembly and replace.

Parts Used:

-

Gregory from Louisville, KY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

15 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the pump had died

First I removed the two screws that hold the pump in place. I then pulled the pump out and replaced it with the new pump.

Parts Used:

-

loudvik from glendale, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

15 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

door assembely had a snapped piece of plastic in unit.

I released the door gasket and unscrewed the unit .Labeled the connections. then reconnected reattached, then put gasket back on. Worked like a charm!

Parts Used:

-

DANIEL from STRATFORD, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

12 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Face Clips on dispenser drawer

I unclipped the old drawer parts from the broken drawer and replaced the old parts onto the new drawer and slid the whole drawer back in the washing machine. It took longer to type this that it did to repair the washer. No tools needed at all.

Parts Used:

-

david from spring hill, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

13 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washing machine wouldn't drain

i removed the front panel, then removed the old pump by taking off the clamps and disconnected the wiring. The new pump had to be reversed before connecting, but it was so easy.

Parts Used:

-

Siobhain from Ashland, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

11 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

drum vanes broke

placed small plillips screwdriver in center hole of old vane and pulled vane toward front of washer and lifted up out of slots. (You need to press down tabs in center of drum slot to insert new ones) Placed new vane at front of slot and squeezed togeather so both sides went in slots and with screwdriver in center hole of vane pushed to rear of washer till vane locked. Incerted screw that came with kit to hold in place DONE.

Parts Used:

-

vernon from middlebourne, WV

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

13 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

I had tried to clean the small basket type screens at the rear of the inlet valve but both of them disintegrated

Following the instructions on your page I was able to see quite clearly what needed to be done. I received the new part promptly and my machine is now working fine. However, the ongoing story with the dryer is another matter.

Parts Used:

-

George from INMAN, SC

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

15 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Thumping vibration on spin cycle

Remove the front lower panel. Remove the 4 plastic pins mounting the shocks using 1/2 inch short socket to hold the detent down as per included instructions. All plastic pins were stuck in place so used needle nose pliers to pull or push out. Lube the pins with grease before reinstall to help them go through the new shocks. Use the included lock nuts to lock the four legs in place as low as possible. Start the washer and level each leg while running so you can tell if the vibration is going away. Tedious method but worked.

Parts Used:

-

Kerry from Pasadena, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

11 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

drum pulley kept getting loose and wobbling. Hub wore out making permanent tightening impossible

Simple. Remove the drive belt from the pulley. Next remove the retaining screw and remove the old pulley. Put the new pulley on the hub, then insert the retaining screw and tighten securely. Last, replace the belt over the motor and hub pulley. This was the most difficult part as the new belt was quite tight. But once I convinced myself it was the right belt a little more effort yielded results and the belt fit fine.

Parts Used:

-

Richard from Long Valley, NJ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

11 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!