AGM499W2 Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Old lint filter was broken

-

Ann Marie from Beaufort, SC

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

hum from motor, drum stopped

Motor bearing was shot - in and out play on the spindle, loud hum from motor and cut out after a couple minutes. Was a bad roller that put too much strain on motor I guess. Well, actually there wasnt much left of the old roller - most of it had been ground to black dust...No problems swapping motor, all rollers, belt and shafts out, although you have to pay attention to how the motor was positioned on the original. It will only fit tightly enough to let the snap-rings close when the motor is correctly positioned. On mine that meant that the multi-plug was rotated a little further than the old one, now it bumps the bottom of the dryer nearly. In short, don't try and force the snaps closed around the bearing collars. If they don't go with only moderate effort on a flat blade screwdriver, then it's incorrectly positioned. Hopefully get another 15 years on this dryer now !

Parts Used:

-

Colin from Eastbrook, ME

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!

sreaching metal on metal sound with a added loud squeal for your listening pleasure.

Hardest part was getting the dryer apart. mine was held together by two snap in clips on the top front pryed those up with a flat head screwdriver then 4 hex head screws and i was in. i watched a couple of YouTube videos of different types of dryer repairs. i am not a mechanic by any means but i would say the repair was very easy. parts were shipped fast so i was up and running quickly and for a lot less money. plus i earned alt of browned points with the wife.

Parts Used:

-

KYLE from PECATONICA, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Dryer not turning on.

Researched the common problem with "dryer not turning on", and tested the top three problems. Removed the dryer front casing and door, unbolted front dryer plate. Used a volt meter on two of the temp gauges, which were fine. Removed the upper back plate of the dryer to the wiring for the knobs and buttons. Used the volt meter on the dryer start button, which was also fine. Went back around to the front and removed the door switch. Tested it with the volt meter and bingo. Replaced that part, dryer works like normal.

Parts Used:

-

Carl from Uncasville, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

loud humming noise

Parts came quickly and were correct. Installation was easy after watching video. Made the dryer a little quieter found that it is the motor that is the main source of the noise.

Parts Used:

-

Jeff from Colorado Springs, CO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

"Unusual Noise"

I wook with tools on my job so I thought I might be able to complete this repair. I viewed the repair video on Partselect's web site and dicided to "GO FOR IT" (after all the dryer was already broke). The dryer noise had to be a moving part so I ordered two drum support rollers, one idler pulley wheel and one belt. If I was going to open the unit up I decided I would not leave an old moving part only to have trouble later. The total parts were less then fifty dollars, so if this did not fix it I would not be out a bundle that could have been applied on a new unit. I was not willing to invest more in the aging unit (ex: motor). The parts arrived in less then three working days. The dryer in the video was a differnt model then mine so I had difficulty removing the front. After the actual repairs got started I had it back together in about two hours. I believe one of the Drum support rollers was the problem I could not reproduce the noise by hand during repairs so I was not sure that was the problem. But one of the drum rollors was not turning as free as the other and niether of them turned as well as the new ones. I marked the wires as instructed in the video for easy replacement. My repair time maybe longer then most as I did this repair on my own. After restoring the power and pushing the start button the noise was gone :) making the dryer a much quieter unit. Brian H., Illinois

Parts Used:

-

Brian D. from Mattoon, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer would heat for only a minute, then not re-ignite

Remove the two screws holding the door and lift straight up. Remove the two screws on oppostie side. Face can now be removed by pulling straight out at the top, then lifting face up off of tabs at the bottom. The two coils are at the bottom, held in by a retaining bracket. Remove the screws that hold the bracket. Replace the coils by unplugged their wires. That's it!

Parts Used:

-

Steve from Glendora, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Motor hummed but would turn with assistance

Lived with operating the dryer by helping spin the drum and then closing the door quick for a couple weeks. Replaced the roller, etc, but when that didn't do it, I ordered the motor. The motor replacement wasn't too tricky. The tricky part was that I initially tried to replace it in the dryer to save time or effort. Take everything apart that comes apart, including the vent fan attached to the motor. Get the motor on the floor in front of you, snap it in place and put it all back together. Not too difficult.

Parts Used:

-

Douglas from Rockford, MI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Dryer made intermittant LOUD SQUEAL noises

We replaced the Drum Rollers, Belt and Glides the first weekend. This DID NOT stop the noise(very loud squealing noise). I decided it had to be the Idler. Instead of replacing just the Wheel, I replaced the whole unit. Took the front of the Dryer off again, took out the Tumbler, removed the 2 screws on the motor assembly tray, moved it a couple inches forward to gain access to the Idler. R&R the Idler( a little contortion for the arms and wrists, but not horrible) and put it all back to together. Works perfectly and ZERO NOISE. YOU CAN DO THIS. Just be patient and give yourself an hour to save $180.00!!!

Parts Used:

-

DSC from Anza, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Socket set, Wrench set

Was this instruction helpful to you?

Thank you for voting!

hi temp therm unit

Well I first attemptede the repair wthout following the online instuction's, I dont recomend it.After some 30 minutes wasted trying to fit my hands in and droping the screw a couple of times, I decided it was time to remove the duct that supplies the air thru the lint trap, after that the repair was a breeze

Parts Used:

-

John from West Milford, NJ

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

would not heat

changed fuse,radiant flame sensor. no help. bought a new dryer. i don't think the gas valuve was opening.everything seemed to be working properly,just no gas.

Parts Used:

-

marc from bristol, WI

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!

Screeching noises

My dryer was making some awful noises. First thought was the belt. Eventually isolated it to the wheel on the idler lever. I had the driver taken apart and could cause the noise by turning the wheel by hand. I decided to replace the support rollers and drum glides at the same time. I highly recommend watching the installation video. I can't tell you how much it helped to see the repair done. Especially the magic incantation on how to open up the dryer to make the repair. For me the most difficult part was getting the new belt on during re-assembly. There is very little room to work underneath the drum to connect the belt to the idler pully and motor. I was successful in connecting those first and then working it around the drum second.

Parts Used:

-

Doug from Cincinnati, OH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Socket set

Was this instruction helpful to you?

Thank you for voting!

The ignitor would lite, but no gas from the valve, then ignitor would shut off

It was a fairly simple repair to perform with the dryer in place. I simply opened the bottom/front access panel to start, the door removes if you pull up after opening. Then I disconnected the two and three wire connector to the two coils. Next I removed the bracket screws that fasten the coils to the valve assembly. This was a little difficult with the screw closest, because of the small clearance and #1 sized phillips(stubby would work well.) The rear screw I managed to remove by using both a small flathead screwdriver(hex shaped shaft) and an adjustable cresent wrench. At this point, it was a simple matter of installing the new coils and the bracket, and then reconnecting the two plugs. It almost made me want to do laundry.

Parts Used:

-

Lee from Madisonville, KY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!

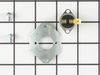

Dryer would not heat

Hardest part was getting to the area where the parts were. Only needed to take off the lower front panel. Thought it was a thermostat but was only the fuse. Replaced fuse and thermostat and worked fine

Parts Used:

-

Leon from Fort Valley, GA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Loud squealing sound on startup goes away when warmed up

Pretty much followed the instructions on the video on the website, very helpful! My model takes 2 rollers, and 2the glides, it wasn't obvious when I ordered the parts that I needed 2 of them. However I installed 1 new roller and 1 new Glide as well as the new belt and the tensioner pulley. Definitely take time to clean out the inside of the dryer it will be very dirty if you have never cleaned it before. Also remember to grease any new rollers. dryer was quiet and ran perfectly after this install.

Parts Used:

-

Kevin from Parker, CO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!