11025292501 Kenmore Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Pump but not spin-oil leaking-agitation noise

Replaced AGITATOR DIRECTIONAL COGS (4) looking instruction video . Replaced CLUTCH LINING KIT following video of this site "WASHER REPAIR-REPLACING THE CLUTCH ASSEMBLY". Replaced SEAL, GEARCASE COVER and NEUTRAL DRIVE ASSEMBLY as follow: 1)CLUTCH Assembly and motor removed, took the GEARCASE on a bench vise to hold in place and the long shaft up side. You can get help from other person to hold secured in place instead a vise.2)Following a youtube video I tested gearcase with a reversible drill using DIRECT DRIVE MOTOR COUPLING PART next To transmission side instead of electrical motor. Drill turning counter clockwise drive the long shaft oscillating (it agitate via agitator cogs). Drill turning clockwise run the exterior sleeved part around shaft (upper side of metal gear inside gearcase and fixed on top to clutch to get washer spin). My experience was didn't rotate so we had to take apart gearcase cover.3)Unscrewed and removed gearcase cover. Cover was sticked by old seal gasket so a screwdriver helped me to remove it.4)Cleaned joint removing old gasket.5)Repeating drill test I realized big nylon gear did'nt rotated and removed uppercut clip with pin pliers with care for not lose the pin. Removed the next washer, the plastic gear and found a plastic part with a tooth broken. This part is with NEUTRAL DRAIN ASSEMBLY so replaced assembly following part instructions. I recommend take pictures in order to reassemling and use ALLEN WRENCH 5/32'' inches.6)Fill up to half of gearcase with 16 ounces (about 1/2 of case) of gear oil supplied by PARTSELECT or automotive gear oil SAE 85w90 or SAE 90.7)Replaced SEAL, GEARCASE COVER. HARD TO REMOVED AND REPLACE! Take care not break!. I had to use a piece of metal tube and a vise.8)Applied automotrice black seal gasket silicone around the cover joint and case.9) Replaced the cover and reversal instruction video.THANKS to this site I get excellent service and Enjoyed with my toy.

Parts Used:

-

Alvaro from CLEMENTON, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

11 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The wash cycle did not start.

First I removed the plastic panels on each side the control panel. Each side was secured by a phillips screw. Once the screws were removed the side panels were easily removed. I tilted the panel back to the rear of the washing machine to expose the lid switch. I first took a picture with my camera phone to ensure installing the switch correctly. I removed a small screw that secured a green ground wire. The lid switch was removed by lifting the plastic catch with a flathead (or slot) screwdriver and uplugging the switch. Reverse the steps and install the new switch. Secure and tighten the green ground wire. The lid must be lifted to properly seat the lid's guide arm into the lid switch. Replace the side panels and tighten the phillip screws. Test the wash cycle using a low water level. It took me 5 minutes to install this part. I am a attorney not a mechanic.

Parts Used:

-

Dwane from Cincinnati, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

10 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Crossed threaded plastic on old valve was leaking

Removed screws on top of machine to remove the control unit out of the way. Then used large regular screw driver to pry out the two clips that hold the back of the washer tight to the top frame. This allows the back to come away from the machine enough to get the water inlet valve free. Didn't have to remove the bolts at the bottom of the back of the machine (they were pretty rusty) Just removed the single screw holding the water inlet valve in place, slid it down and away from the back cover and could fish it out to the side and disconnect the hose (with plyers) and slide off electrical clips (make a note of which clip goes to which valve.) I removed the part first so I could make sure I was ordering the right one. When the part came (very promptly by the way) it went back together easy. Only question was regarding reinstalling the wires since I didn't mark which way they went. I knew which one went on the Hot and Cold but didn't know if it mattered which clips went on each terminal. Figuring it was AC guessed it didn't matter so put it together the way the connectors seemed to want to lie naturally. Put it together making sure no hoses or wires where pinched or rubbing against sharp edges. Replaced the rubber washers in the hoses and made sure the hose connectors turned freely (they had been rusted a bit and didn't turn on the hose freely and I think this was the start of the cross threading problem) This time the hoses went back on very easily, screwed them hand tight not forcing anything at any time (DIDN"T USE PLIERS!). Tried water and no more leaks. Washer filled faster also, think this was because the screens on the water valve were plugged. I'll have to remember to take the hoses off and make sure the screens are clear every couple years or so. If you are having slow fills, suggest you check this first before tearing in to the machine.

Parts Used:

-

David from Amity, AR

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

11 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

tub oscillation

placed washer on side and installed new pads

and returned washer upright

and returned washer upright

Parts Used:

-

leonard from phil campbell, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers

12 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washing machine not draining

Tilt machine on its side,snap off the two retaining straps and remove the pump and sanded the shaft on the electric drive motor to remove rust ,Install new pump and retaining straps and unit now running great.

Parts Used:

-

michael from princeton, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers

10 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replaced ring that broke and washer that was bent on the edge.

Took the agitator out and gearbox off unhook wires from motor and take off water pump, replaced the parts and put back together. Pretty easy to fix. However, I still haven't got my problem fixed. Originally the washer wouldn't spin after the rinse. I put on a new coupler and it worked for a few loads, then something smelled hot and started stinkin the house up so I opened the washer lid and smoke rolled out. Turned it off. Took the moter off and checked it and it would barely turn at all. Replaced the motor with a new one. Still wouldn't spin. Put on a new clutch assembly. Still wouldn't spin. Bought a new capacitor thinking that would do it. Still don't SPIN!!! (The ring and washer I replaced was just a casualty, not any of the problem).

Parts Used:

-

Kim from West Liberty, OH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench (Adjustable)

22 of 47 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would not spin a full load.

!. Removed agitator from inside

2.Removed outside cabinet

3 Removed pump, motor, and transmission.

4. Slid the entire drive unit out of the tub from the bottom

5. Removed the clutch assy. and installed new.

6. Reverseed the procedure to re-assemble.

2.Removed outside cabinet

3 Removed pump, motor, and transmission.

4. Slid the entire drive unit out of the tub from the bottom

5. Removed the clutch assy. and installed new.

6. Reverseed the procedure to re-assemble.

Parts Used:

-

Ralph from Newbury Park, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

11 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

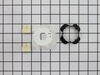

Darn thing hadn't "Agitated" for about 10 years!

After removing the bolt (7/16" head), and using a pair of pliers to remove the 3-4 in deep "cup", it was immediately obvious how to assemble the new cup and pawls (ratchets).

Orienting the black "bearing" was not so obvious, but on closer inspection of the illustration, it became clear. The four "ears" of the bearing go closest to the pawls. The little tabs that are co-planar to the ears fit into the four grooves of the new cup.

And here's the trick (besides making REALLY, REALLY SURE how the pawls orient)--Soak the black bearing piece in hot water to soften it up, and let it slide over the cup better. If you don't, you risk breaking it. If you do, it slides over and "clicjs" into place, with the ears resting right against the bottom lip of the cup, capturing the pawls.

Installation back into the washer is obvious.

The thing works like a charm! It hasn't worked this well for a decade!

Orienting the black "bearing" was not so obvious, but on closer inspection of the illustration, it became clear. The four "ears" of the bearing go closest to the pawls. The little tabs that are co-planar to the ears fit into the four grooves of the new cup.

And here's the trick (besides making REALLY, REALLY SURE how the pawls orient)--Soak the black bearing piece in hot water to soften it up, and let it slide over the cup better. If you don't, you risk breaking it. If you do, it slides over and "clicjs" into place, with the ears resting right against the bottom lip of the cup, capturing the pawls.

Installation back into the washer is obvious.

The thing works like a charm! It hasn't worked this well for a decade!

Parts Used:

-

Stephen from Cornwall, NY

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would not Agitate or spin out. Also noticed an oil leak.

I followed instructions provided from Parts Select for removing and replacing the coupler assembly, and also instructions for changing the clutch assembly. I also took it's transmission apart (socket set and flat screwdriver required), drained the old oil, cleaned it, added new 90W gear oil. The instructions covered the swapping of parts very well. Cleaning up the oil spill took as long as changing the parts.

Parts Used:

-

Jonathan from BRANDON, VT

-

Difficulty Level:Really Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

9 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer tub off balance and noisy

The repair was fairly simple and while it made the spin operation quieter and and a bit more stable, it still gets out of balance. Disconnected power, shutoff supply lines and disconnected them from the unit.

Laid washer on its front and replaced the two more visible springs fairly easily from underneath using a little leverage with a 2 x 4 to take any residual tension off the springs.

Then I turned the washer over on its back (gently and with a little support (board or old thick towel) so the weight of the unit didn't rest entirely on the water intake connectors

Again, lifted the tub with 2 x 4 and disconnected the power and control connector to the motor to make a little more room to get to the spring.

If you do this, be sure to re-connect that connector before you put the washer back and test, otherwise it will fill and then sit.... I had to siphon the tank out, disconnect everything, flip it over and re-connect that power connector!! After that the unit ran better than before, especially on the spin cycle. Over all this washer is 15 years old and worn a bit so we are still careful not to overload it and balance the loading as much as possible. Large bedspreads and king size sheets or mattress covers will always spin out of balance but for 90% of regular washing it was an improvement.

Laid washer on its front and replaced the two more visible springs fairly easily from underneath using a little leverage with a 2 x 4 to take any residual tension off the springs.

Then I turned the washer over on its back (gently and with a little support (board or old thick towel) so the weight of the unit didn't rest entirely on the water intake connectors

Again, lifted the tub with 2 x 4 and disconnected the power and control connector to the motor to make a little more room to get to the spring.

If you do this, be sure to re-connect that connector before you put the washer back and test, otherwise it will fill and then sit.... I had to siphon the tank out, disconnect everything, flip it over and re-connect that power connector!! After that the unit ran better than before, especially on the spin cycle. Over all this washer is 15 years old and worn a bit so we are still careful not to overload it and balance the loading as much as possible. Large bedspreads and king size sheets or mattress covers will always spin out of balance but for 90% of regular washing it was an improvement.

Parts Used:

-

Gregory from Kent, OH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top half of agitator wasn't moving

First, I wrestled off the top cap of the agitator. Then, I unscrewed the bolt and took out the cam. I noticed that the agitator dogs were worn smooth. I replaced them, put it all back together and VOILA! I bought the whole agitator kit, not knowing what I was going to find, because I wasn't a Magtag repair woman. It ended up that the cam that came in the kit was too big for my washer anyway. Luckily, all I needed was 4 plastic dogs. The price of the whole kit was so inexpensive anyway, it was no big deal. Especially because, I was looking to buy a new washer or a big repair bill. This website is great! Thank you.

Parts Used:

-

Debra from Orange, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Tub off center. Upper agitator not driven.

Pop off the softener dispenser. Pull the cover/ seal out of the upper agitator. With 7/16" socket and extesion bar, remove bolt and pull upper agitator straight up and off. dump out old assembly and replace with new assembly. Set back in place and replace bolt. Repair kit comes with good instructions and new rubber O ring for bolt cover/ seal. (thanks).

The suspension spring takes more effort but not hard. with washer laying on face I used a piece of 2x4 to pick up the tub in the direction of the broken spring. Put the new spring through the wire hook loop and snake it through the slot in the frame and you can see how it locks in place. With the 2x4, push the tub toward the new spring until you can hook it through the slot on the tub frame. Done. Parts cost less than an estimate from a service call and I finished the job in 30 minutes, which includes unplugging the power cord, turning off the water and taking off the hoses so I could lay the washer down. Saved the website in my favorites for the same great prices and fast shipping next time.

The suspension spring takes more effort but not hard. with washer laying on face I used a piece of 2x4 to pick up the tub in the direction of the broken spring. Put the new spring through the wire hook loop and snake it through the slot in the frame and you can see how it locks in place. With the 2x4, push the tub toward the new spring until you can hook it through the slot on the tub frame. Done. Parts cost less than an estimate from a service call and I finished the job in 30 minutes, which includes unplugging the power cord, turning off the water and taking off the hoses so I could lay the washer down. Saved the website in my favorites for the same great prices and fast shipping next time.

Parts Used:

-

Thomas from Addison, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Socket set

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Machine agitated during cycle but would not spin clothes dry.

Followed the excellent video instructions. They say you can perform the repair without removing the enclosure, but when I saw how easy it was to remove it, it definitely improves the access and speeds the repair. Have a piece of wire handy to to hold the pump assembly out of the way. Installed new clutch kit and it runs like a champ.

Parts Used:

-

Kurt from Bremerton, WA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

spin cycle was not working / poor

Unplugged the appliance. turned off inlet water and removed hoses. popped the cap off hiding the bolt that keeps the agitator in place and pulled the agitator off. tipped the washer on its front . disconnected the Wire harness. removed the 3 bolts that hold the pump, motor,clutch, (drive assembly in other words). pulled the Drive assembly out of its resting spot removed the bad clutch and replaced it with the new one. then reassembled in reverse order.

Parts Used:

-

Craig from Plano, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Socket set

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would not wash,spin or drain.

I thought that the lid switch was the problem why the washer would not perform the drain or spin cycle. I broke the lid switch by moving the wires around. I rigged it so my daughter could use it by screwing a screw in the switch til the new one came in. After a few days, the machine stopped working again as stated above with the motor. I purchased a new Whir-pool washer for her and later found a white wire that connects to the electric motor was burnt around the connector in that only one tiny wire was still attached. I reconnected the wire in the connector and the washer started working again.

Parts Used:

-

Michael from Covington, LA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!