International Parts

- Search your model number to find:

- Genuine OEM parts guaranteed to fit

- Free manuals and guides

- Repair instructions and videos

Popular International Parts

- Drum Not Spinning

- Marks left on clothes

- Noisy

- See more...

Thank you. Read more...

- Marks left on clothes

- Noisy

- See more...

2. Removed 4 screws from inside the dryer, to take off the blower housing.

3. Removed 4 screws and took out the large metal piece which supports the drum at the front. Removed the drum.

4. Replaced the two rollers that support the drum in the rear. Cleaned the pins they run on, and oiled very lightly. Also replaced the idler roller. I was surpirsed to see that these rollers use plain bearings, not ball bearings.

5. On the front support piece, drilled out the rivets for the glides, and replaced the worn out glides with new parts. Applied a little glue (3M weatherstrip adhesive) to the cork pieces, to glue them to the metal. Attached the plastic pieces over the cork pieces, and riveted in place using rivets that came with the glide kits.

6. Replaced front and rear felt seals. This was not as tricky as I expected it to be. They were held in by metal tabs. Glued the ends where they came together.

7. Replaced the felt blower seal. Glued to the blower housing.

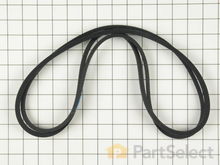

8. Reinstalled the drum, installed new belt, which came with good instructions (luckily).

9. Reassembled front support piece and the front of the cabinet.

I also cleaned the lint from the cabinet and from the vent hose.

In general, the job went without a hitch, and the machine probably has quite a few years left, despite the fact that it's 18 years old. This gives me a good feeling.

I'd say this would be challenging, though, for someone who is not pretty experienced with machinery repair. Also, the cost of the parts was significant enough that it would not have been unreasonable to have opted for a new machine. Read more...

- Light not working

- See more...

- Drum Not Spinning

- Marks left on clothes

- Noisy

- See more...

- Noisy

- Too hot

- See more...

- Noisy

- See more...

Through basic troubleshooting, discovered the motor had seized up. Since the unit was about 10 years old and it had to be disassembled for replacement, the decision was made to replace "likely to fail mechanical components including motor, belt, both rear drum rollers/shafts, idler arm pulley/assembly/wheel, associated washers, snap rings and both front glides. Reviewed the PartSelect website and drawings, ordered the parts and they delivered on time. Buy the correct sized snap rings at a local hardware, they're much less expensive. Also once inside your dryer, you'll likely find alot of lint to vacuum out...have fun.

I went online and Googled several resources that showed how to remove the front dryer panels, as well as PartSelect repair stories. From that point on, I took photos as I was disassembling so I would know how to put it back together. Utilize pictures or whatever system you prefer to keep track of taking something apart and putting it back together.

Remove the dryer door, then the front panel Disconnect wires to the light, dryness sensor and door switch. Note belt and pulley configuration that is near the motor-this will help you later when reinstalling the belt. Also note if the ribbed side or the flat side of the belt is against the outer drum wall. Remove the door shroud.

Slip the belt off the idler pulley wheel. Remove front drum support, then dryer drum Note which end of the dryer drum is the front and the orientation of the glides on the drum support. Discard old belt. Drill out and remove the old front glide supports, then install/rivet the new glides.

Remove both old rear drum rollers/shafts, washers, etc. The rear drum roller shafts are secured to a back bracket by a hex nut....feel around you'll figure it out. Replace new roller shafts. Lightly grease using a high quality silicon grease, then replace new washers, roller, snap ring, etc

Carefully unplug wiring harness on motor, there are fragile clips on each end. Don't forget a separate ground wire from the harness is attached to the motor mount bracket. Carefully release tension on the idler arm spring. Using the correct size nut driver, remove three screws (on this model) then take out the motor/idler arm assembly. Remove the old idler arm/pulley assembly. Remove the motor mount clips on each end of the mount (I used a wide blade screwdriver). Remove and replace the motor. Motor configurations changed after Whirlpool bought Maytag, so orient it correctly insuring mounting gasket "nubs" on each end of the motor correspond to the cutouts on the motor mount. Reinstall the motor mount clips. Replace the new idler arm assembly/pulley wheel; grease moving parts with high quality wheel bearing grease. Replace motor/mount bracket assembly back into the dryer. Replace ground wire to motor mount bracket and plug wiring harness back in. Reinstall idler arm spring.

Place belt back on the dryer drum and move into place on rear rollers. Reinstall front drum support. Dryer drum should turn relatively easy. Insure belt is oriented on the drum correctly before connecting belt to motor shaft end and idler arm wheel pulley (the picture you took comes in handy here).

Reinstall the rest of the parts in reverse. Read more...

- Drum Not Spinning

- Noisy

- See more...

After removing the screws to the front door and panel I removed the wires to the door switch. Carefully I removed the belt and removed the drum. I took the time to vacuum all of the lent from the inside and and remove from all the wiring, motor and heating elements, etc. I replaced the drum rollers, belt, front glides and a buzzer that was on the blink. I reassembled the dryer and unforetunately the dryer was still squeeking. I later repeated the process and found that the tensioner wheel for the belt was the culprit. I cleaned then greased the bearing portion and replaced it. I reassembled the dryer a second time and now it's quiet as a mouse. By the way, you will need a rivet gun to replace the front glides and I recommend you give the belt tensioner wheel a good inspection the first time.

If your dryer is squeeking, go ahead and order the tensioner wheel also, it's a little money spent toward making sure you get rid of the noise! It might save you a lot of time and trouble. Read more...

- Noisy

- Not Heating

- See more...

2. Removed two bolts at bottom front of machine and took off the bottom front panel.

3. Removed three bolts from black plastic exit vent and took it out to give more room to access everything.

4. removed two wires and screws on the limit thermostat. Did the reverse to place the new one.

5. Removed wires (remembering placement), then holder screw. rotated the Gas Dryer Sensor counter clockwise to release the bottom tab so the sensor can be taken off the flame tube. Did the reverse to place the new one on.

6. Removed the one screw on the gas/flame tube that holds the bracket and igniter inside the flame tube. Removed the wires fro the igniter (remember placement) Slid the whole assembly toward the back of the machine to get the tube off the gas valve then rotated the whole assembly counter-clocwise to release the tab on the left side of the bracket. This was a little tight and had to work with it a bit to get the tab out and slide the whole piece out of the flame tube.

7. Once the tube and igniter were out i removed the scree that holds the igniter and replaced with the new one. Made sure no dust, etc. was in the piece.

8. Did the reverse to place the tube/igniter back into the flame tube.

9. Carefully and forcefully removed the wire connectors to the two coils. These were tough to get off. Removed the two screws that hold the bracket that holds the two coils in place. Slid the coils off the spindles remembering which one has the two wire connection and which one has the three wire connection and the way they went on. Replaced the old with the new. Placed the bracket onto the new coils and made sure the little bumps on the top are in the holes in the bracket. Tightened the screws to hold the coil bracket. Reattached the wire connectors to the coils making sure they go ALL the way back on.

10. Vaccumed everything I could to get lint, dust, etc. out.

11.Replaced the black vent plastic.

12 Made sure the exit vent on the back was not crimped or clogged. Checked the little flap door where the vent goes outside to make sure it opens and closes super easy to no air flow is restricted.

13. For testing I left the bottom panel open. Make sure you closed the door, reconnect the plug and turn the gas valve back on. Hit the go button on autodry or timed dry. The door must be closed to create the closed circulation of the system so the fan sucks the flame into the tube otherwise the flame will not fire deep into the tube and will set off one fo the overheat sensors. After hitting the go button your drum will start to rotate, then a few seconds later you'll hear a click and your igniter will start to burn bright orange. Another click and the gas should flow and ignite.

14. This shows that you've fixed the ignition problem. I just replaced everything I thought that could be wrong in stead of hunting and trial and error. All the parts were about $137 so I thought it was worth making sure.

15. IMPORTANT: If during your test the flame turns off after a little while then turns back on only to turn off again, don't panic. This happened to me as well. I found that you need to run the dryer with wet clothes in the dryer. The wetness in the clothes will keep the autodry sensor from shutting off the dryer since there will be moisture in the exhaust. If it's on timed dry the wet clothes will cool the exhaust air and keep the overheat sensors from turning the heat off. So no heating of dry clothes to get out wrinkles. Just dry the wet clothes. This is all I did and it's been working great so far. Good Luck! Read more...

- Burning smell

- Leaking

- Noisy

- See more...

I pulled the washing machine away from the wall and tilted it bacwards and found the pump belt was off the pully and the drive belt was badly damaged. I replaced the 2 belts which took no tools and about 3 minutes to accomplish then resecured the front panel, pushed back in place and leveled. Complete repair from diagnosis to back in operation took less than 15 minutes. Read more...

International Appliance Types

- International Dryer Parts

- International Fridge Parts

- International Refrigerator Parts

- International Washer Parts

Popular International Models

Below are the most popular International models we have. Enter your model number in the search box to find your model.

- LDE9806ACE Electric

- LAT7304AAE Top Loading

- RSW2400EAE

- LDE8426ACE Electric

- LDE9806ACM Electric

- RSW2400EAB

- RSW2400CAE

- RSW2400EAM

- RSW2400CAB

- LAT7304AAL Top Loading

- LAT7304ABE Top Loading

- MUG15MNAWW Gas

- RSW2700DAE

- RSW2700EAE

- RSW2400CAW

- RSW2700DAM

- LAT7304AAM Top Loading

- RSW2400CAL

- LDE8426ACM Electric

- LDE8426ADE Electric