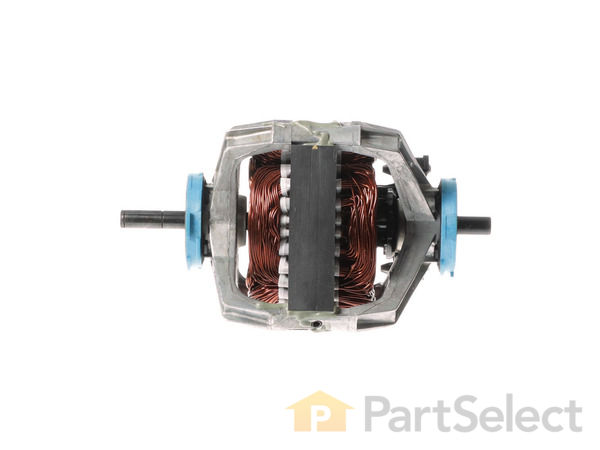

Drive Motor - 60Hz 115V W10410999

Rated by 16 customers

Easy

1- 2 hours

Ratings submitted by customers like you who bought this part.

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

Drive Motor - 60Hz 115V Specifications

How Buying OEM Parts Can Save You Time and Money

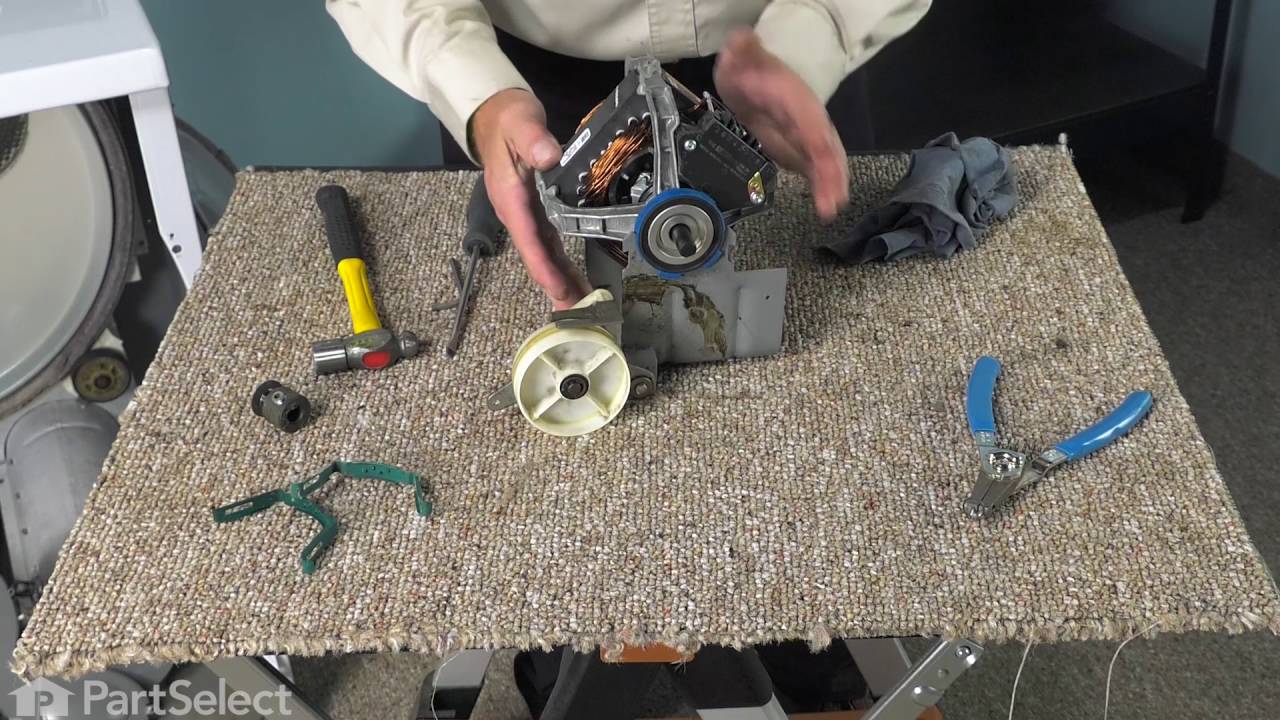

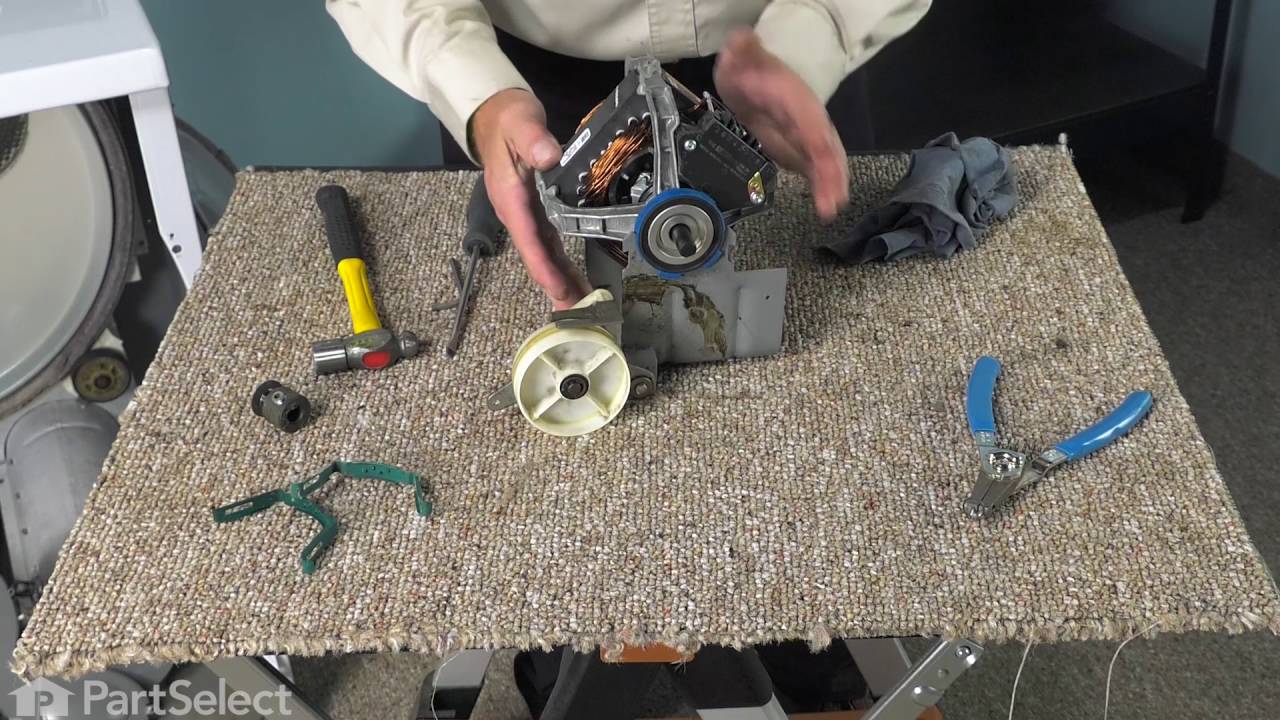

Replacing your Maytag Dryer Drive Motor - 60Hz 115V

-

5 Stars 10

-

4 Stars 2

-

3 Stars 1

-

2 Stars 0

-

1 Star 1

- < Prev

- 1

- 2

- Next >

- < Prev

- 1

- 2

- Next >

- < Prev

- 1

- 2

- Next >

Like the video stated:

Remove two screws at the bottom of the front panel to remove the panel while disconnecting the door switch wires. Since I had an old switch, I took the three wires and plugged them into that so I would remember where each one went .

I believe after that was the fan housing with a few bolts, then the drum. I reached through the small back panel to loosen the belt by moving the tensioner back, then removing the drum. The fan was secured by a snap ring and a spring loaded hose clamp that required a small set of pliers.

There were two bolts that held the motor in; once removed, the motor slid out with the bracket. The tough part was using the screwdriver to get the clamps off that hold the motor to the bracket, but the video helped with that.

The new motor did not come with instructions on how to wire it, so I had to go to this site and find somebody who had asked the question. The video did not do all that great a job in showing me where the wires go and since the motor was different than my REAL MAYTAG motor, I had no idea where the wires went, but I found someone who asked the question and he got the answer, so I was able to figure it out.

It had been over a month since I had taken the dryer apart so I went back to that video which, except for the wiring and that tiny little deflector plate, provided excellent detail of how to install everything. I had trouble deciding where I wanted the wires to make sure the drum didn't rub on them, so after it was all back together, I watched the drum rotate with the dryer running from that little panel in the back.

One thing that saved me was every time I took something off, I kept the bolts with that item. It only became a problem when my friend came over and saw the dryer in pieces. He just had to give me his own lecture about fixing dryers and when he talks he has touch everything, so all my bolts are going flying! I was like, "What are you doing? Are you gonna put this back together for me after you lose all my bolts?"

-

David from SILVERDALE, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

The biggest hurdle for me was that the motor came with a new switch that required a different wiring configuration. No wiring diagram was included. Several others had posted questions about wiring in the ... Read more Q&A and unfortunately PartSelect kept copy/pasting the same confusing and incomplete answer over and over:

"The Yellow goes to T6, Red to T5 Black to T2, blue to T1 and the white you will remove the blue jumper lead between the switch terminal 4 and 1/4" protector tab, connect the grey harness lead to the 1/4" protector tab."

Reading that doesn't tell me what to do with the white wire, doesn't address that my blue and white wires were crimped into the same connector from the factory, doesn't address that I had 2 black wires crimped into the same connector from the factory, and doesn't address a factory ground wire that connected the frame of the OEM motor to the bracket that the motor sits in.

With all the other excellent info supplied by PartSelect, this was surprising and frustrating. The sales dept ignored an emailed question from me, and the Q&A section didn't allow me to post a question.

Searching the internet, I found a wiring diagram on aceappliancesd dot com that addressed my dryer's OEM wiring configuration. Here's what I ended up with:

TI - Blue and white, crimped together into a single connector

T2 - Black & black, crimped together into a single connector (the wiring diagram I found said this should be black & brown, but they both look black to me)

T5 - Red

T6 - Yellow

1/4" Thermal protector tab - Grey (from the harness)

The new motor switch had a grounding tab with nothing connected to it. I removed the screw holding that tab into the switch and connected the (also grey) OEM short ground wire from the motor frame to the mounting bracket.

I had to cut 2 of the pieces of tape holding the OEM wiring harness together in order to get enough slack for all the connections to reach. If you do this too, make sure all the wires are still clear of the moving parts and the hot bits. You may need to retape the wires together at a different location to keep things tidy.

I also laid the belt over the drum and put 2 pieces of tape over it to hold it in place while I got the drum positioned, then I reached through the back access panel to loop the belt around the motor pulley and idler. Once that's done, just reach over the top of the drum and peel the tape off. I found that much easier than trying to loop the belt by reaching through and past the drum.

-

Peter from REDONDO BEACH, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

-

Raymond from CYPRESS, CA

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

-

Cody from BENTON, TN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

-

Jerrt from MC KEES ROCKS, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

Details:

1.) I turned off power to the dryer.

2.) I removed the front panel by removing the two screws on the bottom edge with a stubby #2 Phillips s ... Read more crewdriver, then rotated the panel out until the clips released on the top edge.

3.) I noted the wire connections to the door switch, and then removed the three wires from the terminals on the door switch. I removed the door switch wire harness from the clips and moved it out of the way.

4.) I removed the blue wire from the dryness sensor and set it aside but left the other wire attached since it would come off with the bulkhead.

5.) I removed the front tumbler bulkhead by removing the four hex-head screws that secured it with a 5/16" nutdriver. I set the bulkhead aside.

6.) I reached back under the tumbler drum and slipped the drive belt off the idler pulley beside the motor, then pulled the tumbler drum straight out the front of the dryer. I also removed the belt as it was going to be replaced.

7.) I removed the two hex-head screws holding the guard plate over the temperature and thermal overload sensors with a 5/16" nutdriver and then removed the plate.

8.) I removed the single hex-head screw holding the blower housing to the base of the dryer with a 5/16" nutdriver, then removed the six hex-head screws on the front blower cover with a 3/16" nutdriver. I removed the front blower cover and set it aside.

9.) I removed the retaining ring holding the blower wheel from the blower shaft with a retaining ring pliers, then removed the spring clamp from the blower wheel hub with a pair of needlenose pliers. I used a flat-blade screwdriver to gently open up the slots on the blower wheel hub and was able to pull the blower wheel straight off the shaft.

10.) I removed the four hex-head screws attaching the rear blower housing to the motor mount with a 5/16" nutdriver, then removed the rear blower housing, making sure to gently remove it from the exhaust pipe as well.

11.) I detached the idler pulley spring from the idler pulley arm.

12.) I removed the two hex-head screws holding the motor mount to the base of the dryer with a 5/16" nutdriver, then slid the motor mount to the right do detach the tabs on the base from the mounting slots. I disconnected the wires from the motor (red, blue, grey, black and yellow) and moved the wiring harness out of the way..

13.) I pulled the motor and motor mount out of the dryer and placed them on the workbench. Then I removed the retaining ring from the blower end of the motor shaft with retaining ring pliers.

14.) I removed the drive pulley from the shaft with a 3/16" hex key to loosen the set screw. This required a few taps on the key with a hammer.

15.) I removed the motor clips from each end of the motor with a flat-bladed screwdriver, pushing the locking tab on the clip down until it disengaged from the hook on the motor mount.

16.) I removed the motor from the motor mount and discarded it.

17.) I placed the new motor into the motor mount and aligned it so that the frame of the motor would not come in contact with the tumbler drum. I put the new motor clips back on with a flat-bladed screwdriver.

18.) I slid the drive pulley onto the drive shaft and lined it up with the belt mark on the idler pulley. Then I tightened the set screw with a 3/16" hex key and several light taps with the hammer.

19.) I placed the rear blower retaining clip onto the blower end of the shaft with the retaining ring pliers.

20.) The motor came with no wiring diagram, and the manufacturer also changed the starting switch with a different model. Some research on the PartSelect.com site yielded instructions on the correct terminal connections. The motor came with several 1/8" crimp connectors to replace the original 1/4" connectors on 2 of the wires. I used the wire strippers to cut the ends off the red and yellow wires, stripped 1/4" of insulation, and the used the crimping tool to crimp new 1/8" connectors on the red and yellow wires.

21.) I replaced the motor mount and motor back in the dryer and connected the wires to the correct terminals. There was a blue jumper wire on the motor that I removed per instructions so that the grey wire could connect to the motor thermal overload terminal.

22.) Reassembly was then the reverse of disassembly. The only tricky part was putting the new belt on and getting it threaded through the drive pulley and idler pulley in the correct orientation. While I had the drum out, I took the opportunity to lubricate the drum roller wheel bearings and the idler pulley bearing and to clean out the accumulated lint from some 20 years of operation.

The job took about 2 hours total, a good portion of which was spent figuring out the correct wiring for the new motor.

The dryer now works quietly and starts without issue.

-

Peter from HARMONY, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

-

John from COHUTTA, GA

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

-

Lee from Maidens, VA

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

-

Daniel from Rochester, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

1. Remove the back access plate to release the belt from the pulley.

2. Remove the two screws at the bottom front of the dryer, rotate the front to release it at the top. R ... Read more emove the wires from the door status switch.

3. Remove the 4 nuts holding the drum support frame and pull straight out.

4. Putting one hand inside the drum and supporting it, gently pull the drum toward you until it clears the rollers. Reach in along both sides of the outside top of the drum and slide the belt off the back of the drum. With a hand inside supporting the weight of the drum tip the drum slightly forward and out the front. Set it out of the way.

5. Remove the two bolts holding the thermostat cover (silver odd shaped metal plate at the front of the dryer).

6. Remove the dryer blower cover plate by removing the 6 bolts holding it to the blower housing with a short ¼” nut driver. Remember to remove the bolt holding the plate to the bottom of the dryer.

7. Release the door status wire from the clips on the left side of the dryer and set the blower housing plate to the right, out of your way without removing the wires.

8. Remove the blower wheel by removing the snap-ring at the front of the shaft and then removing the collar- compression clip.

9. Pull out the blower wheel (this was a bear as it was very tight on the shaft – the shaft-collar of the blower wheel has grooves in it. We used very small screw drivers to carefully pry the segment of the collar between the grooves away from the shaft and used a penetrating oil and with a very slight rocking force muscled the blower wheel off then removed the rear snap-ring from the motor shaft.

10. Release the 5 wires attached to the motor.

11. Remove the ground wire on the back of the motor by backing the screw out.

12. Release the front and back motor clips (Use a large straight-blade screw-driver to press down and out on the end of the clips.

13. Lift out the motor.

14. Remove the rear pulley from the motor using an Allen wrench and transfer it to the new motor (We used heavy duty thread locked on the Allen set screw. – When we removed the pulley it was necessary to heat the Allen set-screw area with a propane torch to soften the thread-locker cement. IF YOU NEED TO DO THIS MAKE SURE YOU LEAVE PLENTY OF TIME FOR THE PULLEY TO COOL BEFORE YOU HANDLE IT!

15. Set the new motor in the support frame, ensuring the lips of the vibration isolation rings are pointed down to slip over the frame and are not facing up towards the clips ( makes clip installation much easier).

16. Hook up the wires, following the color coding on the motor controller you are attaching to.

17. Hook up the ground wire on the back of the motor.

18. Reinstall the rear snap-ring, blower wheel (went on a lot easier than it came off), front snap-ring, collar-compression clip, blower housing front cover (Including the bolt to the dryer bottom) ,

19. Re-route the door switch wire up the left side and secure with clips.

20. Reinstall the thermostat cover,

21. Reinstall the drum and belt (use scotch tape to temporarily secure belt) , the drum front support frame (ensure the felt seals for the drum and the blower cover are properly aligned and seated correctly),

22. Reinstall the belt through the back access panel over the pulley and idler wheel (make sure the belt smooth side is against the drum, the grooved side against the pulley and the belt is inside the belt guide on the idler wheel and remove the scotch tape from the belt). Make sure no tools are in the dryer cabinet.

23. Rotate the drum clockwise a few revolutions to align the belt and reinstall the rear panel.

24. Hook up the door status wire before you set the front cover and install the 2 screws,

We previously replaced the front drum felt seal and the tumbler glides, the belt and both drum rollers.

-

MARCELLE from DUNDEE, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Wrench set

- < Prev

- 1

- 2

- Next >

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- 3

- Next >

23 people found this helpful.

11 people found this helpful.

4 people found this helpful.

3 people found this helpful.

3 people found this helpful.

3 people found this helpful.

3 people found this helpful.

3 people found this helpful.

2 people found this helpful.

1 person found this helpful.

- < Prev

- 1

- 2

- 3

- Next >

Manufacturer Part Number: W10410999

Item is in stock and will ship today if your order is placed before 4:00 PM Eastern Standard Time.

If your order is placed after 4:00 PM EST, the in stock items will ship on the next business day.

Item is not in stock and usually ships 3-5 business days from the time you place your order.

Item is not in stock and usually ships 10-15 business days from the time you place your order.

This item is no longer being made by the manufacturer, and cannot be added to your shopping cart.