SWSG1031HQ0 Westinghouse Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

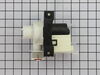

water pump broke

My Husband did the repair it took less than 15 minutes. He popped the front off the washer. He then unscrewed two screws and removed the pump assembly. He popped the new pump in, and put in the tow screws. Then he put the washer front back on replacing two screws. It took all of five minutes. I am so pleased it was so easy. I told him next time I'd do the repair and he could watch!

Lil

Lil

Parts Used:

-

Lili from Jamestwn, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

22 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My old lint filter had a few holes in it.

I got online and found that everyone was charging a king's ransom for a piece of plastic. Your ransom was slightly less. Then I paid $7 shipping and handling for the part which came packed in a box six times its size...I guess all that cardboard costs a mint. I opened the box, removed the lint filter, and put it into my dryer....voila! No more holes!

Parts Used:

-

Marc from Malden, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

23 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the burner wouldn't ignite

UNPLUG the appliance. After removing the top of the dryer the front is easily removed. To make life simple I disconnected the wire harrness at the quick disconnect and placed the door/front away from the workspace. I removed the bracket holding the coils in place and replaced the old with the new coils. replaced the front and top panels and pugged it in! Good as new!! I originally ordered the wrong part and PART'S SELCET.COM refunded my money no problem! I will bookmark this site and use it again.

Parts Used:

-

Michael from Newbury Park, CA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

21 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water not draining

It turned out that the pump was fine. There is a filter within the rubber bellows between the washer drum and the motor. You need to remove the entire bellows to get to it. Just remove the motor and you can un-clip the hose tensioners. They are exactly like the ones you would fine on most foreign cars - just compress with pliers and move back on the hose. Clean out the plastic filter. A small nail had worked its way through the plastic filter and lodged in the motor impeller. Removing this nail and reassembling, it all worked as new! I kept the pump and motor as a future spare rather than return it.

Parts Used:

-

Harold from Denver, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

22 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer machine wouldn't move

first removed the 2 screws disconected the terminals, installed new switch connected wires back and test washer and it worked like new, i put a Jumper to get the washer to work while i got the parts. Also i received the parts in 24 hrs. Thank You.

Parts Used:

-

Luis from Riverside, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

23 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Gas flame turns off after a while. No more heat.

Fixed it eventually with part PS470049 ('M' Series Ignition Coil Kit). See separate story.

The flame sensor did not fix it but read on for info on how to replace this part. Before replacing this part, I should have read another posting in a different web site about the ignition coils: if you see a red glow inside the burner unit but the flame does not come on, then the problem is likely to be with the coils, not the flame sensor. However since some users here had solved the problem by replacing the flame sensors, I figured I'd try it. The setting for "More dry, less dry" never worked either so maybe this would fix two problems at once.

This dryer is a stacked front loader sitting on top of our washing machine. Opening the little front door (lower left side) is easy once you figure out that a little screw below needs to be removed. I almost broke the door trying to pull it open. The sensor is attached to the side of the flame area cylinder. It was hard to remove both the screw and the part itself from the slots as it's very springy. In fact when I finally removed it, it dropped to the base of the unit and sparks went flying as one of the electrical clips touched the metal (ground). Tip: first disconnect the electrical lead coming from the back of the unit to the ingnition block and later I used rubber gloves just in case. (I could not access the plug/outlet in the back). I installed the new part easily, though I was confused by the electrical leads: the white wire connects to the lead that has a red plastic dot on the side, but I think that must be a mechanical part and not a (wrong) marking, while the red connects to the other lead. Anyway, I connected it the same way I found it and put it back. Reconnected the other electrical wires and closed the door.

This did not fix the problem which turned out to be with the gas valve coils: as they get old, they turn off the flame when they get hot, even though the dryer keeps on turning. To read how to replace that part, search for comments under part number PS470049 ('M' Series Ignition Coil Kit). I don't know whether replacing the flame sensor is going to fix the "more dry-less dry" function, will have to see. Still, this website is great. Our dryer is a Westinghouse bought in 1991 (almost 20 years old!) and with this fixes it's just like new.

The flame sensor did not fix it but read on for info on how to replace this part. Before replacing this part, I should have read another posting in a different web site about the ignition coils: if you see a red glow inside the burner unit but the flame does not come on, then the problem is likely to be with the coils, not the flame sensor. However since some users here had solved the problem by replacing the flame sensors, I figured I'd try it. The setting for "More dry, less dry" never worked either so maybe this would fix two problems at once.

This dryer is a stacked front loader sitting on top of our washing machine. Opening the little front door (lower left side) is easy once you figure out that a little screw below needs to be removed. I almost broke the door trying to pull it open. The sensor is attached to the side of the flame area cylinder. It was hard to remove both the screw and the part itself from the slots as it's very springy. In fact when I finally removed it, it dropped to the base of the unit and sparks went flying as one of the electrical clips touched the metal (ground). Tip: first disconnect the electrical lead coming from the back of the unit to the ingnition block and later I used rubber gloves just in case. (I could not access the plug/outlet in the back). I installed the new part easily, though I was confused by the electrical leads: the white wire connects to the lead that has a red plastic dot on the side, but I think that must be a mechanical part and not a (wrong) marking, while the red connects to the other lead. Anyway, I connected it the same way I found it and put it back. Reconnected the other electrical wires and closed the door.

This did not fix the problem which turned out to be with the gas valve coils: as they get old, they turn off the flame when they get hot, even though the dryer keeps on turning. To read how to replace that part, search for comments under part number PS470049 ('M' Series Ignition Coil Kit). I don't know whether replacing the flame sensor is going to fix the "more dry-less dry" function, will have to see. Still, this website is great. Our dryer is a Westinghouse bought in 1991 (almost 20 years old!) and with this fixes it's just like new.

Parts Used:

-

Giuseppe from San Francisco, CA

-

Difficulty Level:Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

22 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the belt was all worn out , it make a lot of noise

i took out the two back screws lift the top.

took the two bottom front screws , lifted andtook off the front panel.took off the old belt an intall the new one in a circular motion put the panel and top back on and done.

took the two bottom front screws , lifted andtook off the front panel.took off the old belt an intall the new one in a circular motion put the panel and top back on and done.

Parts Used:

-

CARLOS from BEALETON, VA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

26 of 38 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

black streaks on clothes from failed drum glide and felt

first i used a flathead to lift up the top of the dryer. there were two prongs that you press in to detach the top.

then there were two screws on the inside along each side that i needed a phillips to remove. one screw on each side.

i also needed to detach a cable and cut the tie.

from there, it was easy to pull off the front of the dryer.

the first noticeable thing was HOW much lint there was inside! so out came the vacuum and away went all the dust and lint.. a TON of it.

then i used a sharp knife to remove all the existing upper and lower felt. that took awhile, and i got as much as i could.

then i applied the TOP felt, nice and center, and from there, the FELT was applied, which fit perfectly. I let it dry/set for about 2 hours.

for the Front drum glide, AN IMPORTANT NOTE! i ordered only ONE drum glide, but you need TWO! I had to order a second one, and i dont know why they dont come in pairs.. so the front drum glides snap on pretty easily to the front of the drum. press hard and they SNAP into place. once they are snapped on, you just put back on the front, replace the screws, re-connect and re-tie the cable, and close the lid!

then there were two screws on the inside along each side that i needed a phillips to remove. one screw on each side.

i also needed to detach a cable and cut the tie.

from there, it was easy to pull off the front of the dryer.

the first noticeable thing was HOW much lint there was inside! so out came the vacuum and away went all the dust and lint.. a TON of it.

then i used a sharp knife to remove all the existing upper and lower felt. that took awhile, and i got as much as i could.

then i applied the TOP felt, nice and center, and from there, the FELT was applied, which fit perfectly. I let it dry/set for about 2 hours.

for the Front drum glide, AN IMPORTANT NOTE! i ordered only ONE drum glide, but you need TWO! I had to order a second one, and i dont know why they dont come in pairs.. so the front drum glides snap on pretty easily to the front of the drum. press hard and they SNAP into place. once they are snapped on, you just put back on the front, replace the screws, re-connect and re-tie the cable, and close the lid!

Parts Used:

-

Rodney from Mountain View, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

20 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Machine would not spin.

Once I figured out that it would not spin because it did not drain. Unplug machine and remove the back pannel. Locate the drain pump on the bottom of machine. Remove the power wires and the screws holding it to the bottom. Then use a pliers to remove the hose clamps ( was easer for me to tip the machine forward ). Be prepaired to catch or soak up extra water from lines. The hardest part to the install is the limited room you have to work with. Install screws to hold the pump in place then install water lines, power wires and back pannel. Only thing left is to plug it in and watch for leaks.

Parts Used:

-

Jeff from Weyauwega, WI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

20 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The upper part of the agitator wasn't working.

I removed the bolt holding the agitator in the tub and lifted the agitator out. There seemed to be a part near the top that was not engaging. I decided to order a replacement to see if that was the problem (my local repairman had guessed the problem was in the transmission and said I should just replace the machine.) I ordered the part online and it arrived in only two days. I was very happily surprised by the speed with which I received the part. I put the new agitator in, tightened the bolt and ran a load of clothes. All worked perfectly

Parts Used:

-

Bob from Estes Park, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

21 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer drum would squeak and squeal until warmed up, but progressively got worse as the days drug on.

First pry up on the front edge of the top panel of the dryer which is held in place by snap in clips. Pivot the top open and support against wall or other taking care not to pull on wiring harness. Next remove the 2 screws that hold the front panel in place. These are located on the inside of the front panel. The front then snaps loose also. Remove the plastic drum stop located at the top edge of the front of the dryer. Next I removed the 3 drum screws located inside at the back center of the dryer. Next you can you need to remove the belt the motor located at the rear vent panel on the back. Slide the now loose drum out exposing the rear bearing. With a 5/16 end wrench, loosen the 2 screws on either side of the bearing retainer. Assemble the new bearing bracket to match the old one. Apply a liberal amount of supplied lubricant to the pivot ball and plastic retainer. At this point it was helpful to have someone at the rear of the dryer hold the new retainer bracket against the back of the dryer while I tightened the new bearing assembly in. Assemble dryer in reverse.

Parts Used:

-

Chad from Glyndon, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Wrench set

19 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer wouldn't spin

Received lid lock within 24 hours, fixed washer within 10 minutes...up and running. Thanks.

Parts Used:

-

KELLEY from KANSAS CITY, MO

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

22 of 33 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Tub wouldn't drain

First I removed the front panel,then set the timer to run. It began the drain,spin cycle, pump ran, but no water went out. Shop-vac the water out,removed hoses from pump,took out mounting screws from base, unplug pump plug. check hoses for debris since they're open, the impeller was broken. ordered the part . Mount the pump to the base, put the hoses on, plug in motor and replace front panel. plug into wall

Parts Used:

-

Brian from Murfreesboro, TN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

19 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Final Spin Burning Smell

Removed 2 screws at bottom of the front panel - removed front panel by sliding the panel down about 1/2 inch and then away from the appliance- v belt is removed by pushing the tensioner pulley to remove tension from the belt and turning the pulley untill the belt is removed instalation is a simple reverse of the process. I did't have a repair manual so every step was trial and error untill I was able to complete the repair.

Parts Used:

-

NELSON from MAYWOOD, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench (Adjustable)

17 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water Flooded Floor

First I took sides off the washer. I then took screws out of the Drain pump holder. Unclamped the two pipes from it. Undid the wires to then drain pump. Screw in the new pump hardware. Plugged in the wires on side of the pump. Reclamped the pipes. Put sides back on washer and it worked. That easy and took less then 30 minutes. I am no handy man so thats how easty it was.

Parts Used:

-

Matthew from Weyers Cave, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

18 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!