SWS833HQ0 Westinghouse Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

drive belt old and stretched

unplugged machine. pried up with large regular screwdiver on top washer lid. removed two phillips screws bottom of front panel, had to use rubber mallet to drive front panel down to remove as was rusty and old. removed old belt using screwdriver. put new belt under tub pulley and put belt on small pulleys. kept moving tub and springs by pushing on tub. Took several tries to get new belt to go on the large tub pulley but finally did it. I used the instructions you gave for replacing broken drive belt and it worked. replaced front panel and two phillips screws, put top back on and away it went.

Parts Used:

-

George from Sault Ste. Marie, MI

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drive Belt Was Noisy-Slipping

I just popped up the top front using a large straight (slotted) screw driver, then removed the 2 screws at the bottom front, then the whole front panel popped down about a half inch to be lifted out of the way. I found the old drive belt way down under the motor (still attached as normal), very near the floor and removed the worn out belt by hand, and replaced it with the new belt by hand also. The spring loaded belt tightener- idler wheel makes this a very simple process to accomplish. Then, I replaced the front panel-- all done. Works like new.

Parts Used:

-

Steve from Carrollton, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking through the main tub seal

-Remove front panel - 2 screws

-Remove the top panel - 2 screws

-Disconnect the lid switch from the top panel - 2 screws

-Remove the agitator cap - unscrew

-Remove the agitator - This was a bit difficult and required a lot of jiggling but it eventually came off

-Remove the inner drum - 5 bolts at the bottom

-Remove the drum mount - 2 bolts and then it got really difficult. A lot of penetrating blaster, wire brushing, jiggling, and some strategically placed hammer taps (don't damage the threads.

-Remove the seal

-Clean up the inner and outer seal seating surfaces

-Rinse and repeat in reverse (pun intended)

-Remove the top panel - 2 screws

-Disconnect the lid switch from the top panel - 2 screws

-Remove the agitator cap - unscrew

-Remove the agitator - This was a bit difficult and required a lot of jiggling but it eventually came off

-Remove the inner drum - 5 bolts at the bottom

-Remove the drum mount - 2 bolts and then it got really difficult. A lot of penetrating blaster, wire brushing, jiggling, and some strategically placed hammer taps (don't damage the threads.

-Remove the seal

-Clean up the inner and outer seal seating surfaces

-Rinse and repeat in reverse (pun intended)

Parts Used:

-

Rob from DACULA, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

transmission wore out

After struggeling the most with lifting out the inner drum and then the wash drum. I realized when the job was complete a better way. 1. Take the top off the washer. 2. take the front off the washer. Then disconnect all wires and hoses from assembly One small hose on the tub and the pump hose at the bottom. 3. at the bottom of the overall assembly there are 3 braces holding the tub assembly with 2 springs on each brace. Go under and remove the springs and then lift the whole assembly out into the middle of the floor. 4. remove the top cap off of the agitator. 5. remove the agitator. 6. if you are lucky and the bolts are not seized in the block that holds the shaft remove the small steel block from the bell and remove the bell. 6. Slide the inner tub up and off the shaft and again if all goes well the outer wash tub should slip up off the shaft as well. 7. remove the drive belt from the motor and transmission.

Parts Used:

-

Tim from Flemington, WV

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leveling leg sheared off

Put machine on dolly. Tilted it on its back. Put screw driver into sheared leg and unscrewed broken leveling leg. Then screwed new leg in and tilted machine back up.

Parts Used:

-

Joseph W from WEST PALM BCH, FL

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

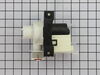

The water did not drain at all . You could hear the pump spinning , but it was not .

After making sure there was no blockages and the pump was not jammed I knew it was time for a new one . Unplug the machine and turn off the hot and cold water . Remove the two screws on the bottom of the front of the machine and push down on the panel it should come right off . Make sure all the water is drained out of the tub use a wet/dry vacuum to suck out all the water if needed . Then with the vacuum empty squeeze the clamps that hold the hoses on the pump and push them out of the way . Use the vacuum to suck up any leftover water, as you remove both hoses . Unplug the one set of wires going to the pump . Remove both screws and the pump should now be loose . Do the same thing in reverse to install the new pump . Other than dealing with the water it should take under 15 minutes . Good Luck

Parts Used:

-

Lawrence from STATEN ISLAND, NY

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken belt

Pry up top from front remove 2 phillip screws at lower front panel slip belt under tub pulley then around motor pulley push belt tensioner towards back of machine slide belt onto tensioner pulley. (Done)

Parts Used:

-

Sharon from TEMPLE, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Smell of rubber under dryer. Inspection proved belt cracked and shinny worn spot.

Installation was easy, however watch repair instructions video for your model number to easily remove front access panel.

Parts Used:

-

Fred from WOLVERINE, MI

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Bottom "Screw", which is the front leg of the washer was broken.

Tilted the clothes washer back to provide easy access. Then after scrubbing the floor - which took most of the time of the repair, screwed out the broken leg and screwed in the new leg or SCREW. Easy peasey.

Parts Used:

-

Linda Lahann from Freehold, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

3 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would only let cold water in,then not fully cycle

Disconnect power,take water hoses off using pliers,they are really tight,remove 2 philips head screws,pull 2 wire connectors off and water fill hose squeezing wire clamp and sliding clamp back on hose.reverse to install.Works like a champ.

Parts Used:

-

George from Ketchikan, AK

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

over fill caused door to come open

removed top cover to access valve dissconnected hoses and wires then unscrewed valve and replaced

Parts Used:

-

Bill from Unionville, PA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer was not spinning

We have a washer/dryer stack type. For a week or so, my wife mentioned that washer is louder than normally is, shortly, the washer stopped spinning and the clothes were finishing soaking wet.

I opened the front panel sheet and saw the broken belt, ordered the belt online. The belt arrived in 2 days, and the actual belt-replacement took 10 minutes. The washer functional like new.

I opened the front panel sheet and saw the broken belt, ordered the belt online. The belt arrived in 2 days, and the actual belt-replacement took 10 minutes. The washer functional like new.

Parts Used:

-

Mohamad from Chicago, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

burning rubber smell

Poped up top, removed front pannel (2 phillip head screws) observed failed belt. Replaced belt. Tensioner can be held back by hand so it was easy. Works great. Part Select Rocks! I put in the model number and bam, there was my needed part, 3 days later it was in my hands. This was after me wasting time driving around town trying to find it at home depot type stores to no avail. I'll never do that again. This website makes repairing appliances a snap. Gotta love on-line shopping! woo hoo

Parts Used:

-

Lewis from Thornton, CO

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Impellar was broken on the washer drain pump.

Removed front panel and unplugged wire connector to drain pump. Loosened two hose clamps and removed hoses the unbolted drain pump from washer frame. Simple removal and even simplier installation of new drain pump.

Parts Used:

-

Michael from IOWA PARK, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

water filling in machine without turning on

I looked up the repair on You Tube and it looked easy! Take off the top of the machine (unplug and disconnect water first), 2 wire connections and 2 screws to mount. The only problem I had was screwing the mounting plate on the machine. It needed some help enlarging the hole a tad, I used an awl. Reconnect the water and plug in.This Granny rocks!

Parts Used:

-

Christine from DALLAS, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!