SVD48600WC Jenn-Air Range - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

lcould not see the lights on the clock or temperature on the control panel

The parts came with no instructions, we started to take off , the front panel , finally took off the 4 screws under the panel, then the two small ends caps on either side. the only problem we had after being carefull to study the part as we took it off , was the ribbon strip, that stayed connected to the stove. after we tried to put all back together, the exhaust fan kept coming on. There are two small

holes that need to be aligned in the replacement part. also to get the strip out and back in you need to press and pull up on the small black notches on either of the strip.

holes that need to be aligned in the replacement part. also to get the strip out and back in you need to press and pull up on the small black notches on either of the strip.

Parts Used:

-

charlette from FREDERICKSBURG, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Self cleaning would not work on the oven

Removed old part with a pair of pliers and plugged the new part into place.

Very simple and the self cleaning feature works again.

Very simple and the self cleaning feature works again.

Parts Used:

-

Crucita from Albuquerque, NM

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broiler blement failed

Sunday, four days before Thanksgiving, our oven would not bake properly. A quick check indicated the top element was not working. What to do? Where to get a part in time to fix for Thanksgiving dinner? The answer was easy - PartSelect. I had the part in my hands on Tuesday AM. Oven was fixed in 15 minutes and my wife was baking pies within an hour. All worked well and yes, we had a wonderful trukey dinner. Great service !

Parts Used:

-

Donald from Hudson, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

8 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

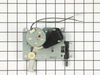

Downdraft Blower Failure

Blower motor stopped working and the breaker tripped. Horrible smell! from the somewhere in the oven. Looking at the wiring diagram told me that there was a relay board feeding he motor, but I had no idea where it was, which took a little Internet searching to find it. Finally seeing that it was in the rear I was happy to see that there was enough flexible gas line to pull out the stove enough to check the board, which was fried. I replaced the board and then looked for the reason it smoked and found that the blower motor was shorted (and stank horribly).

It was straighforward to replace, but when I put everything back, NOTHING worked at all - no lights on the control panel, nothing. I then checked the voltage across the terminals and saw 240V and was puzzled until saw that there was no 120V to neutral where the plug connected to the back of the stove. The outlet, however, had 120V to neutral. Since it was a molded plug I thought that was not likey to be a cmmon failure, so after killing th breaker I took off the outlet cover that the stove plugged into and found out that the neutral terminal was intermittent.

The neutral contacts were not grabbing the netral terminal on the plug tightly enough and were a little discolored in one spot. All that moving around of the plug while moving the stove probably moved it just enough not to work at all - that thing was a fire hazard that I'm surprised hadn't been the cause of more damage in a house only 12 years old. Rather than try and clean the termnals and trust bending them to be tighter (and worry about metal fatigue) I spent the $10 so that I could sleep better for a tight new 240V 30A outlet.

Everthing works like a charm now.

It was straighforward to replace, but when I put everything back, NOTHING worked at all - no lights on the control panel, nothing. I then checked the voltage across the terminals and saw 240V and was puzzled until saw that there was no 120V to neutral where the plug connected to the back of the stove. The outlet, however, had 120V to neutral. Since it was a molded plug I thought that was not likey to be a cmmon failure, so after killing th breaker I took off the outlet cover that the stove plugged into and found out that the neutral terminal was intermittent.

The neutral contacts were not grabbing the netral terminal on the plug tightly enough and were a little discolored in one spot. All that moving around of the plug while moving the stove probably moved it just enough not to work at all - that thing was a fire hazard that I'm surprised hadn't been the cause of more damage in a house only 12 years old. Rather than try and clean the termnals and trust bending them to be tighter (and worry about metal fatigue) I spent the $10 so that I could sleep better for a tight new 240V 30A outlet.

Everthing works like a charm now.

Parts Used:

-

Steven from Marshfield, MA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

10 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

lighted display very dim to non existant

Thanks to JP in customer service.

TURN THE POWER OFF TO THE STOVE at the breaker box!

I had to pull all the burner knobs off (4ea) and remove the screw under each one. Then open the oven door and remove the screws holding a trim piece on and the hex head screws holding the "touch pad panel" on (was also held on by the screws I had already removed from behind the knobs) 1 smaller screw at each end (total of 2) under there hold the plastic trim on that needs to be moved slightly to let the panel come out. (DON'T OVER TIGHTEN WHEN YOU REASSEMBLE) You hang the panel in the 2 slots provided and remove the old display unit. Gently unplug the 2 wire harnesses and ribbon that actually connect the touch panel to the display PC board. Look for the 2 small holes in the ribbon that will line up with the female part on the board. A piece on the board where the ribbon plugs in will slide up a little and allow you to plug the ribbon in and then push it gently back down. Finish putting it back together and turn power back on at the breaker box. Works perfectly.

TURN THE POWER OFF TO THE STOVE at the breaker box!

I had to pull all the burner knobs off (4ea) and remove the screw under each one. Then open the oven door and remove the screws holding a trim piece on and the hex head screws holding the "touch pad panel" on (was also held on by the screws I had already removed from behind the knobs) 1 smaller screw at each end (total of 2) under there hold the plastic trim on that needs to be moved slightly to let the panel come out. (DON'T OVER TIGHTEN WHEN YOU REASSEMBLE) You hang the panel in the 2 slots provided and remove the old display unit. Gently unplug the 2 wire harnesses and ribbon that actually connect the touch panel to the display PC board. Look for the 2 small holes in the ribbon that will line up with the female part on the board. A piece on the board where the ribbon plugs in will slide up a little and allow you to plug the ribbon in and then push it gently back down. Finish putting it back together and turn power back on at the breaker box. Works perfectly.

Parts Used:

-

Dan from Burlington, IA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Self Cleaning did not work.

Remove burner knobs, Removed 7 screws from bottom of face plate. Removed screws from 2 alluminum or steel spacers I guess you could call them. I let the Op Panel hang carefully not to stress wires. I marked all wires of the Latch asm. Removed the four screws holding it in and carefully removed the wires. Replaced in opposite manner and self cleaning works. The oven tried to start the cycle but I noticed the latch never triggered. When the function first stopped working I was able to apply slight force to the door and the latch fired. So after replacing the door switch it still failed to work. So latch asm was the official fix. So I have had to replace the latch asm and the Op Panel for being dim. I don't think this model is very good. But Partselect.com is great easy to find parts and good prices. Very pleased with my experience.

Parts Used:

-

Rick from Beaverton, OR

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Wrench set

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The range burners would not catch a spark and ignite. They would just keep clicking with no ignition.

I had an appliance repair rep do the replacement. He made it look relatively easy.

The repair man first turned off the breaker to the range and confirmed there was no power to the range.

After lifting off the range top cover exposing the burner igniters, he unhooked and removed the igniters. He opened the lower oven door exposing the screws which hold the front knob plate in position. He took those out. After loosening the knob plate he was able to unscrew and raise the inside cover which exposes the wires and the spark module.

My spark module was located in the front left corner area tucked a little under the knob plate. That is another reason why he had to loosen the plate. The replacement part was a universal part so he had to do a little work on the wire connectors but it only took a couple of minutes. Once he configured the wire ends, he was able to plug in the new spark module and put the top back together again.

The repair man knew exactly what to do and made it look relatively easy. I did not want to tackle this problem because I did not know exactly where the spark module was since some models have them in the back of the oven and the oven has to come out from the wall. Also, the wire connections had to be worked with a little and he knew exactly how to do that.

The repair man took about 45 minutes from beginning to end with most of that time spent getting to the part and putting it back together. The replacement itself took only about 10 minutes.

The repair man first turned off the breaker to the range and confirmed there was no power to the range.

After lifting off the range top cover exposing the burner igniters, he unhooked and removed the igniters. He opened the lower oven door exposing the screws which hold the front knob plate in position. He took those out. After loosening the knob plate he was able to unscrew and raise the inside cover which exposes the wires and the spark module.

My spark module was located in the front left corner area tucked a little under the knob plate. That is another reason why he had to loosen the plate. The replacement part was a universal part so he had to do a little work on the wire connectors but it only took a couple of minutes. Once he configured the wire ends, he was able to plug in the new spark module and put the top back together again.

The repair man knew exactly what to do and made it look relatively easy. I did not want to tackle this problem because I did not know exactly where the spark module was since some models have them in the back of the oven and the oven has to come out from the wall. Also, the wire connections had to be worked with a little and he knew exactly how to do that.

The repair man took about 45 minutes from beginning to end with most of that time spent getting to the part and putting it back together. The replacement itself took only about 10 minutes.

Parts Used:

-

Adrienne from Lake Havasu City, AZ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

6 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

light bulb in water ice freezer door went bad

I didn't. Don't know how to get to light bulb to change it for this specific model

Parts Used:

-

Carl from RIVERSIDE, CA

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers

7 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loose terminal caused block to overheat and break

Removed all terminals and block mounting screws. Repaired one burnt terminal and reassembled. Replacement part was an exact fit and reassembly whnet very well.

Parts Used:

-

Dana from Black Mountain, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

6 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

my oven would not heat to proper temp

I slide the range out and unplugged it from the outlet. I removed the back of the oven ( 8 screws ) using a cordless drill and phillips bit then with a phillips screwdriver I removed the oven sensor (2 screws) then I installed the new sensor , reinstalled the oven back , plugged the range in , slide it back into place and that was it. This repair took about 10 mins and the oven works perfectly. Thanks !

Parts Used:

-

mark from CHAMBERLAIN, SD

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lower panal would not stay in place because plastic fastners were gone.

I inserted the door strikes in the proper position and then snapped the panel in place.

Parts Used:

-

siri from remsenburg, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

high blower vibration

blower wheel was caked with dried grease clumps; replaced blower wheel, urethan foam and 3 motor isolators; blower/fan no longer vibrating cooktop.

Parts Used:

-

Lawrence from Chandler, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

9 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

oven wouldn't heat and showed a error message of function not available

pull oven, remove back pannel and unplug and remove high limit switch. Repair was the reverse of removal.

Parts Used:

-

Eugene from Pampa, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

5 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven was not correctly heating to set temperature

Removed the approximatly 10 screws that hold on both the upper and lower pieces of sheet metal that cover the back of the oven. Removed the screw holding in the temp sensor. Unplugged and removed the old sensor. Plugged in and installed the new sensor (using one of the included adapter wires supplied with the sensor). Put the 2 pieces of sheet metal back on and plugged in the oven.

Parts Used:

-

Trace from Ofallon, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Surface burners would not light

None of the surface burners (two Uni-burners) would light without using a match. I first ordered two replacement PS2089818 top burner spark electrodes. I replace one which was very easy - the electrode just clips into the burner - and I traced the wires down to the back bottom of the stove where I found they plugged into an ignition module. The new electrode didn't help, but since all four burners were out it made sense that the ignition module would be the problem and not the two separate electrodes. So I ordered a new ignition module. It plugged in easily with the terminals well marked like the original. I put the original electrode back in and all four burners now light properly with the desired "tic tic tic" sound with the knobs in the "high/light" position.

Parts Used:

-

James from Gorham, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!