S160 Jenn-Air Range - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Replacing the bulb in the freezer side

Removed the ice brucket,

Removed the light shield by releasing one screw using a nutdriver.

Replacing the bulb and reinstalled the light shield.

Your web site is one of the best and most helpfull service sites I ever used. Just wish that in the future you will ship parts overseas.

Removed the light shield by releasing one screw using a nutdriver.

Replacing the bulb and reinstalled the light shield.

Your web site is one of the best and most helpfull service sites I ever used. Just wish that in the future you will ship parts overseas.

Parts Used:

-

Yafa (and David) from Bothell, WA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

5 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

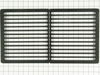

Replace Grease Filter

Just a couple of minutes to left off the cover grid, left out the old filter and drop in the new one.

Parts Used:

-

Gene from Washington C.H., OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

524 of 537 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Blower motor died and I needed to replace it

Most of the repair was obvious as I took the blower apart before ordering the parts. Unfortunately the new motor was significantly larger than the original motor so I had to um. Adjust the position of some of the other parts to fit it in. There was a sheet metal flange that was installed on the other side of the blower from the motor which was designed to focus the air flow into the blower. I used a hammer to ajust the angle of flange so it no longer extended as far into the blower housing.

It works just fine although its a bit louder than the old motor was.

It works just fine although its a bit louder than the old motor was.

Parts Used:

-

John from Berkley, MI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

377 of 384 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner had one temperature--hot, regardless of setting

1. Killed power and removed the regulator's knob, noted the position of the old control.

2. Took off the cover for the center vent and loosened the two screw holding the housing in place--the screws didn't have to come out completely as it is a U-shaped friction hold.

3. Unscrewed the two screws holding the old control switch in place--lifted the housing enough to get at the old switch and carefully pulled it loose--it was a front burner so the control switch was about as far back as it could be but still wasn't that hard to get at.

4. Turned the new switch to orient the wire connectors, then, using a needle-nose pliers, removed each friction connector, one at a time, and fitted them on the new switch (note: one of the wires fitted best if it went under as opposed to around the base of the new switch).

5. Replaced the control back through the housing and screwed it in place, making sure the orientation of the control matched the way it looked originally.

6. Slide the housing back over the two screws and tightened, replace vent.

7. Replaced the knob and turned on the power.

(The above took me about twice as long to write as it did to make the repair and I write professionally but am not a professional electrician.)

Also, I bought a second control switch because, given the age of the unit, I'm sure another one will go. The second one will assure that it won't happen :-).

2. Took off the cover for the center vent and loosened the two screw holding the housing in place--the screws didn't have to come out completely as it is a U-shaped friction hold.

3. Unscrewed the two screws holding the old control switch in place--lifted the housing enough to get at the old switch and carefully pulled it loose--it was a front burner so the control switch was about as far back as it could be but still wasn't that hard to get at.

4. Turned the new switch to orient the wire connectors, then, using a needle-nose pliers, removed each friction connector, one at a time, and fitted them on the new switch (note: one of the wires fitted best if it went under as opposed to around the base of the new switch).

5. Replaced the control back through the housing and screwed it in place, making sure the orientation of the control matched the way it looked originally.

6. Slide the housing back over the two screws and tightened, replace vent.

7. Replaced the knob and turned on the power.

(The above took me about twice as long to write as it did to make the repair and I write professionally but am not a professional electrician.)

Also, I bought a second control switch because, given the age of the unit, I'm sure another one will go. The second one will assure that it won't happen :-).

Parts Used:

-

James H from Oxford, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

105 of 119 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The oven door seal was ripped and was leaking.

The oven seal replacement was very straight forward. Two screws held the door to the arms coming from the oven. I slid the door up off the arm and moved it to a workbench. This whole process should take about 15 minutes, a little longer if your unit is older and you want to clean as you go. Mine was fairly dirty and I gave it a cleaning as I removed parts. Unscrew all screws on the outer frame of the door, including two small ones on the side. Remove the outer frame and then the glass front and set them aside. A few more screws to remove the glass from the inner door, and even more on the remaining part of the door. You should also remove the screws holding the tiny brackets as well to release the portion that holds the oven seal in place. This is very straightforward, just keep pulling screws out until you can remove the old seal.

Once the old seal is out, insert the new one using the wire embedded in the seal as your guide...the gap in the seal goes to the bottom. Put everything back together and re-install the door. My door hinges were spring loaded and took a little effort to move them down so the door can be slipped on. This is a two person job since the hinges do not lock in place, they spring right back up flush with the oven and you cannot install the door. Re-install the two set screws holding the door to the hinges and you are done!

With the new seal in place, it felt a little puffy and the door did not seem to close as flush as it used to. This makes sense since the seal is new. I kept the door locked (like you would to use the oven cleaning cycle). I even kept it partially locked during cooking.

Frankly, the hardest part was the cleanup of nasty grease and dirt that built up over the past decade or so.

Best of luck!

Once the old seal is out, insert the new one using the wire embedded in the seal as your guide...the gap in the seal goes to the bottom. Put everything back together and re-install the door. My door hinges were spring loaded and took a little effort to move them down so the door can be slipped on. This is a two person job since the hinges do not lock in place, they spring right back up flush with the oven and you cannot install the door. Re-install the two set screws holding the door to the hinges and you are done!

With the new seal in place, it felt a little puffy and the door did not seem to close as flush as it used to. This makes sense since the seal is new. I kept the door locked (like you would to use the oven cleaning cycle). I even kept it partially locked during cooking.

Frankly, the hardest part was the cleanup of nasty grease and dirt that built up over the past decade or so.

Best of luck!

Parts Used:

-

Paul from Mickleton, NJ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

90 of 95 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Needed to replace filter

Just placed it at the filter location. Liked the ring feature on the filter for ease of removal for cleaning. My previous ones didn't have such feature. Thank you for filling my order. I bought an extra filter for the future. I'm a big user of my Jenn-Air range. I may soon be needing to replace my griddle. Will be contacting your company then.

Parts Used:

-

Marie from New Smyrna Bch, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

98 of 162 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven door wouldn't close completely

Parts arrived in three days and it was an easy swap of the hinges but the same problem still existed: the oven door wouldn't close completely, so the oven light stayed on and the convection wouldn't work either unless the door closed all the way. The replacement hinge's springs apparently aren't strong enough to close it and the springs aren't adjustable - which is a design flaw. I did correct the problem though, by using three dollars worth of 1" round magnets, which I placed inside the door: they stay put and are strong enough to pull the door tight.

Parts Used:

-

William from Statesville, NC

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

60 of 67 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old grease filter was bent and needed replacing

I simply lifted off the grille in the center of the stove, pulled out the old filter and dropped the new one in. It sits at an angle (right side down, left side up) rather than slotting in to a particular spot.

Parts Used:

-

Linda from Palo Alto, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

70 of 131 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Toggle switch to operate exhaust fan and oven light inop.

First I turned off electrical power to the range by turning off the circuit breaker for the range.

Then I removed the two screws that hold the switch plate to top of front of range. Then I pushed the sw plate back toward to rear of range to disengage it from the guide pin, and lifted the switch plate and switch. Turned the switch plate over and labelled the four wires to the switch. Removed the wire which were push-on. Which allowed me to remove the switch plate completely from the range. At my bench I used my Dremell with a cutting wheel to cut off the two push nuts/washers holding the switch to the switch plate. Removed the old switch and replaced it with the new one. Pushed to the new push nuts/washers provided in the kit, and re-assempled.

Then I removed the two screws that hold the switch plate to top of front of range. Then I pushed the sw plate back toward to rear of range to disengage it from the guide pin, and lifted the switch plate and switch. Turned the switch plate over and labelled the four wires to the switch. Removed the wire which were push-on. Which allowed me to remove the switch plate completely from the range. At my bench I used my Dremell with a cutting wheel to cut off the two push nuts/washers holding the switch to the switch plate. Removed the old switch and replaced it with the new one. Pushed to the new push nuts/washers provided in the kit, and re-assempled.

Parts Used:

-

T from Southfield, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

26 of 31 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner Control not Functioning

Simple Repair!

Turn off Power

Remove four screws under panel.

Remove old burner knob.

Drop Burner Panel from range

Remove 5 wire connectors from old burner control

with pliers

Remove 2 screws that held burner control to range

panel

Install new burner control

Rplace two screws to burner control

Replace 5 wire connectors to new burner control

Replace 4 screw under panel

Replace knob to new burner control

Turn on electricity

Made wife happy!

Turn off Power

Remove four screws under panel.

Remove old burner knob.

Drop Burner Panel from range

Remove 5 wire connectors from old burner control

with pliers

Remove 2 screws that held burner control to range

panel

Install new burner control

Rplace two screws to burner control

Replace 5 wire connectors to new burner control

Replace 4 screw under panel

Replace knob to new burner control

Turn on electricity

Made wife happy!

Parts Used:

-

Randall from Mohnton, PA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

26 of 33 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Just ugly this time`

It's wonderful to get accessories for this 20 year old Jenn-Air. I love it and now it looks like new.

Parts Used:

-

Susan from Chino, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

22 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven Door hinge is broken

One oven door hinge spring was broken. I ordered two hinges to complete the repair.

The repair could not have been easier. I removed the door from the oven an unscrewed the outer frame of the door from the inner door assembly. I unscrewed the old hinge assembly and replaced them with the two new hinges.

I set the door back on the oven and replaced the oven door retaining hardware.

After replacing the retaining hardware, I removed the temporary shipping pins that keep the spring assembly static. Very important: don’t remove these hinge pins until the door is on the oven an the oven retaining hardware is secured.

The repair could not have been easier. I removed the door from the oven an unscrewed the outer frame of the door from the inner door assembly. I unscrewed the old hinge assembly and replaced them with the two new hinges.

I set the door back on the oven and replaced the oven door retaining hardware.

After replacing the retaining hardware, I removed the temporary shipping pins that keep the spring assembly static. Very important: don’t remove these hinge pins until the door is on the oven an the oven retaining hardware is secured.

Parts Used:

-

Hugh from Hopewell, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

22 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven Door wouldn't fully close and light stayed on.

Remove oven door by removing chrome flat plate that holds the hinge in place (one screw at each hinge) and LIFT door off oven. There is a hole in the hinge that you can stick a small nail through to hold the hinge in the "partially open" position for easier removal and replacement of the door (I didn't know this until I received the new hinges, which have a removeable pin in the hole.) After door is off, remove three screws each, on the top and bottom of door, to remove the back half of door and expose the hinges. Remove one screw from bottom of door that holds bottom of hinge in place. Lift out hinge bottom and unhook top of hinge. Reverse process to reassemble. Remove small pins by opening oven door fully. The new hinges did solve the problem. You have to order two hinges for each door. They are NOT sold as pairs.

Parts Used:

-

Jeff from Fremont, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

18 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dual element burner only stays on high

The replacement switch was not exactly as my original and none of the other instructions matched exactly with my unit. So I had to figure it out, but they matched mostly what Micheal from Colliervile wrote. Safety is paramount. Turn off circuit breaker and ensure there is no power to unit with a test light. You don't have to remove the glass top. Open oven door and remove 4 screws at bottom of control panel, then remove two screws on each end while suppoting the panel with one hand. Rest control panel on top of door or hang by wires. Remove two screws to detach switch from panel. I took pictures of the wire placement on old switch and drew a diagram of what color wire went to each terminal. I used the instruction sheet diagram of new switch and marked where each wire color goes. Here is where I put them: DOUBLE BLACK to L1,2; New jumper from P1 to S1; RED to 2: DOUBLE RED to P2; new jumper with small connector from S2 to "element on" indicator lamp (it's longer than and replaces existing jumper); YELLOW to 4a; TAN to 4. The letters in parenthesis on the instruction sheet almost matched up to my old switch so I used them to help with the placement. I didn't have to seperate any compound red wires. Double check wire placement and put it all back together in reverse order.

Parts Used:

-

Sherman from Perry, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers

17 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Seal rap around oven door window was separating from its frame.

The frame and window were supplied as a completed assembly. About 4 other panels had to be removed prior to installing the new window assembly. This was easy to do with a screwdriver removing about 16 screws and then replacing all panels back in place after replacing the new window assembly. No instructions were supplied with the part, but anyone with a little mechanical abillity could do it. You may need a helper to hold panels in place while they were being screwed back in place. Total job took about one hour

Parts Used:

-

Lester from Torrance, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

16 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!