RTW4740YQ0 Roper Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Lid safety switch defective . Lid would not lock allowing washer operation.

Remove small screws on back of top on both sides, slide top forward. No need to remove water hoses. Lift top up to expose switch safety mechanism (black plastic) on front underside of top. Undo screws holding switch mechanism. remove plate cover from back of top and unplug wiring harness. Thread new wireing harness and plug through hole in top and plug in to plug receptor.

Parts Used:

-

Garry from CANON CITY, CO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

17 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The top part of the Agitator was no longer working.

The repair was very easy. The only hard part was due to the age of the machine the cap covering the agitator assembly was stuck on the top.I had to use a very large pipe wrench to loosen it. Other than that the whole repair went very smooth. You will need an extension with the socket wrench in order to reach the screw holding down the agitator.I was very impressed with the service from Parts Select. I received my part very fast and it included everything I needed to complete the job.

Parts Used:

-

Ron from Germantown, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

15 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer lid would not release

Unplug washer. Remove 4 screws from the small plates that hold top to body of washer. Remove cover plate from back of top. Lift top from base and support it on its back. Remove lid lock mechanism. Unplug connector from its socket at the back of the lid. In reverse order install the new lid latch,

Parts Used:

-

Michael from BURLINGTON, NJ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

18 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Smelled a burning odor occasionally

First, I checked the belt before ordering and then decided to order the belt, capacitor, and clutch assembly (if I needed to replace). I replaced the belt noticing the older belt came right off and new one was tighter going on. I replaced the capacitor since I had it handy and it can be known to cause this smell also. After setting washer back up and started a cycle I noticed the spin cycle would not start properly so I thought maybe the capacitor (new one) was faulty or just not the exact match even though it was said to be. I replaced my older capacitor back on and again ran cycle and it ran great. Thus I decided to send the parts which were not used. I would recommend this site as I have used them in the past before on other items. They ship fast and have a great return policy if parts not used.

Parts Used:

-

Paul from E NORTHPORT, NY

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Socket set, Wrench (Adjustable)

16 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

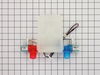

My washer lid lock light kept blinking and the washer would not start

I followed the online video, removed the old part and replaced it with the new part. My washer is working perfectly. It took about an hour to reset.

Parts Used:

-

Janice from GREENVILLE, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

13 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator moves freely in both directions

First I removed the softener bin by pulling it up and off, then I removed the plastic seal by pulling it up and out, then I removed the 1/2 inch bolt with a ratchet and extension, then I removed the upper and lower agitator assembly from the machine and seperated the two by putting my feet on the lower agitator to hold it to the floor and pulling the upper agitator fast and firmly.

Sitting on top of the lower agitator I found the dog ear assembly. I pulled the dog ear assembly off and removed the yellow cap and existing dog ears.

Assembly was reverse.

Sitting on top of the lower agitator I found the dog ear assembly. I pulled the dog ear assembly off and removed the yellow cap and existing dog ears.

Assembly was reverse.

Parts Used:

-

James from NAPERVILLE, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Wrench set

14 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Banging all the time during rinse as if its out of balance

Followed the video, no need to add. Worked perfectly!

Parts Used:

-

christine from SWANSEA, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

14 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer shook violently during spin cycle

Raise top cover, remove tub ring.

Remove suspension rods one at a time by pulling the

rods upward, remove keepers at top,pulled rods out the bottom by tilting washer. Replaced all four rods and installed load centering springs which hadn't been installed from factory. Took 1/2 hour and works like a new one??

Remove suspension rods one at a time by pulling the

rods upward, remove keepers at top,pulled rods out the bottom by tilting washer. Replaced all four rods and installed load centering springs which hadn't been installed from factory. Took 1/2 hour and works like a new one??

Parts Used:

-

Bobby from LAGRANGE, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

12 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer not agitating

This was a learning experience but it appears to have worked out in the end. Our 3 1/2 year old washer was not agitating much and I attributed that to a loose bolt. I would tighten the bolt and it would work ok for a load or two and then stop agitating. I would find that the bolt was loose again. I took a number of steps to try to get the bolt to stay on tight - threadlock, a new bolt, more threadlock, and applying progressively more force on the bolt, with no better results. Yet the repair guys on you tube were saying the bolt only needs to be snug, not super tight - something was amiss. I even went so far as to secure the basket with a rope so I could use two hands on the socket wrench (please don't do this). But when I tried the washer again there was no agitation at all! I observed the agitation output in manual test mode and the bolt was turning in lock step with the shaft but the agitator wasn't turning at all. That's when I suspected that the problem was actually a worn lower agitator. Trouble was that now I couldn't seem to get the bolt off. Turning the wrench caused the shaft itself to rotate so I couldn't loosen the bolt from the shaft. I thought I broke the washer. Then I considered that maybe the shaft was rotating because the washer was in an agitation mode when I turned it off. I went back into manual test mode, made the washer spin, then turned it off. Fortunately, this worked. The shaft was again stationary and, albeit with great difficulty, I got the bolt off.

I removed the agitator, and as a pro would have figured out long before, the ridges inside the top of the lower agitator were almost completely worn down. I realized then that the contact between these ridges and the splines on the shaft is what is supposed to cause the lower agitator to move with the shaft. The purpose of the bolt is just to keep the agitator in the correct position and from coming off the shaft. I had been trying to compensate for the worn agitator ridges by over-tightening the bolt, creating some contact at the top of the shaft. This would work for a little while, then the agitator would start slipping, and the slipping agitator was acting just like a wrench loosening the bolt (until my stupid rope trick, that is.)

So I ordered a new agitator (only the lower agitator was bad, but the price of an entire agitator isn't a lot more than just the lower part and I was reading that the upper agitator parts will wear over time) and another new bolt (because my repeated attempts to over-tighten the first one I ordered had split the rubber gasket apart and worn the bolt head).

The new agitator fit snugly on the splines of the shaft so I sensed no need to use excessive force on the bolt. Just an easy one-handed snug tightening with the socket wrench, using the other hand to hold the lower agitator. The washer is now working again.

I removed the agitator, and as a pro would have figured out long before, the ridges inside the top of the lower agitator were almost completely worn down. I realized then that the contact between these ridges and the splines on the shaft is what is supposed to cause the lower agitator to move with the shaft. The purpose of the bolt is just to keep the agitator in the correct position and from coming off the shaft. I had been trying to compensate for the worn agitator ridges by over-tightening the bolt, creating some contact at the top of the shaft. This would work for a little while, then the agitator would start slipping, and the slipping agitator was acting just like a wrench loosening the bolt (until my stupid rope trick, that is.)

So I ordered a new agitator (only the lower agitator was bad, but the price of an entire agitator isn't a lot more than just the lower part and I was reading that the upper agitator parts will wear over time) and another new bolt (because my repeated attempts to over-tighten the first one I ordered had split the rubber gasket apart and worn the bolt head).

The new agitator fit snugly on the splines of the shaft so I sensed no need to use excessive force on the bolt. Just an easy one-handed snug tightening with the socket wrench, using the other hand to hold the lower agitator. The washer is now working again.

Parts Used:

-

David from EAST AMHERST, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

11 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer wouldn't start - Flashing Lid Light

I checked out the reviews and the recommendation of these "professionals", replaced the part easy enough when it came in. However, it didn't solve the problem. Got an actual professional to come in and see what the problem was, and they determined that gear oil was being leaked and it wasn't worth replacing.

Tried to get a refund and return the part. Was told absolutely not. The money back guarantee is a lie.

Tried to get a refund and return the part. Was told absolutely not. The money back guarantee is a lie.

Parts Used:

-

Marc from HOPE MILLS, NC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

12 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water inlet nozzle was stripped and leak

Remove the front panel and back panel unplug the part unscrewed the part and replace it with the new one

Parts Used:

-

Armand from WESTPORT, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

23 of 48 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Hot water valve would barely open - take 35 mins to fill washer

Pull the washer out from wall

Unplug the Washer

Close the supply line valves

Unscrew the supply lines, use bucket to catch line water

Remove 1 cover plate for elec lines (1 screw)

Remove 2 screws on edge of back plate for control panel

Slide long blade under front of control panel corners, pop the lock clips

Lay control panel forward - controls down

Compare new and old part - looks the same, wires, etc

Remove center screw on back plate cover to remove it

Unplug the elec wires connecting the valves and the control panel

Remove 2 screws holding the water valve outlet

swap out the old values for new valves

Reverse the process - step backwards and reassemble

Took me 36 minutes.

Tested the washer for Hot fill and later cold - both work

Unplug the Washer

Close the supply line valves

Unscrew the supply lines, use bucket to catch line water

Remove 1 cover plate for elec lines (1 screw)

Remove 2 screws on edge of back plate for control panel

Slide long blade under front of control panel corners, pop the lock clips

Lay control panel forward - controls down

Compare new and old part - looks the same, wires, etc

Remove center screw on back plate cover to remove it

Unplug the elec wires connecting the valves and the control panel

Remove 2 screws holding the water valve outlet

swap out the old values for new valves

Reverse the process - step backwards and reassemble

Took me 36 minutes.

Tested the washer for Hot fill and later cold - both work

Parts Used:

-

Kevin from ARLINGTON, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

wash machine walked

-

Elzoria from FROSTPROOF, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

replaced drain hose that was missing

slipped the new drain hose on and with locking plyers slipped the wire clap in place after three trys

Parts Used:

-

Delmar from EAST TROY, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers

11 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wouldn’t drain pump made loud noise

Removed old drain pump and found a sock in the inlet - must have burned out pump because after removing it pump was still defective. Installed new pump in about 30 minutes and off to the races no more issues

Parts Used:

-

REED from BUCHANAN, NY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Wrench (Adjustable)

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!