RTW4740YQ0 Roper Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Agitator loose spinning

Three of the four agitator cogs had broken. The agitator was able to spin freely both clockwise encounter clockwise which it should not be doing. I replaced the cogs as well as a couple additional parts just to be sure but the cogs were the important one. Very easy.

Parts Used:

-

Matthew from AUSTIN, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top agitator did not work

I removed the cover for the softener dispenser on the top of the agitator. Then reached in and removed the cover of the nut and washer which was very sticky and sealed with an o-ring. This took a bit of pressure. Then used a socket wrench with an extension to loosen the bolt and took the whole agitator out of the machine. Then I set the agitator on the floor and with a fine 12 inch long screw driver released the catches while turning and pulling the agitatior with my other hand and holding the lower agitatior on the floor with my feet. I then turned the upper part over and removed the cogs and holding mechanism.

Then I reversed the process after replacing the cogs with the new part. 25 minutes total.

Then I reversed the process after replacing the cogs with the new part. 25 minutes total.

Parts Used:

-

George from Danbury, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

agitator did not turn

I removed the cap over the ratchet mechanism, removed the ut holding the agitator in place, removed the agitator and cleaned all the parts. The assembly for the ratchet dogs was a 3 piece assembly that was included in the kit I bought from Part Select. I also bought a new cap and gasket since my old gasket had broken too. A new gasket was already included in the kit, so I didn't need ot buy the cap. I liked that th ekit included everything I needed and good instructions. parts got to me in about 3 days. Very happy with my Parts Select experience and the fact I saved at least $100.

Parts Used:

-

Mark from Whitehall, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

upper agitator inoperable

Took ten minutes to pop upper assembly off and replace dogs. Note long ratchet or nut diver advisable 5/8.

Parts Used:

-

david from Rohnert park, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top section of agitator slipping on ratcheting dogs

I popped of the fabric softner dispenser at the top auger by appling pressure with both thumbs rather than use the notch provided. This gives access to the agitator mounting bolt which was removed with a deep socket and extension on a ratchet handle. The agitator slipped right off the splined shaft by pulling upward at two points at the bottom. I ordered the complete agitator repair kit which included a part that improved the operation of the top auger, it may have been a factory upgrade at some point on this machine. I did use silicone grease where required and I feel that this is a must for longevity of the thrust washer. If you are ordering the complete kit, the o-ring seal for the inner cap is included. The machine washes like it was new.

Parts Used:

-

John from Brooklyn, NY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer shaking

the repair went well but I still haven't received a refund for the order was was sent incorrectly. Order #22085769 order date 2/3/23

Parts Used:

-

Oralia from DALLAS, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

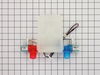

water inlet valve stopped working

used the Parts.com video. I am not mechanical at all, but removed the old part and installed the new part without a hitch. Very happy.

Parts Used:

-

Zoran from ROCKVILLE, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The washer was vibrating very bad on large loads

Using the parts I ordered and following the instructions provided in the video from partselect.com made the repair very easy and solved the problem

Parts Used:

-

Mark from SAINT CLOUD, FL

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer -Maytag Centennial- would NOT agitate. It would run through all cycles as indicated by the lights and even spin at the end, but never agitated. It also did not appeared to go into "sensing" mode at the start. Took a long time to move from "sensing" light to "wash" light. Did not hear or see a

There are a number of videos showing how to do this repair:

>Disconnect power and water - cold, hot and drain.

>Put washer on its side on a stand (low platform) to get to the bottom.

Better than than just laying front of washer on floor.

>Used a drop light to help see bottom.

>Removed Pulley Cover using nut driver - has 2 screws with nut

heads.

>Removed and replaced the Shift Actuator (part provided) using a

Phillips screw driver - 2 green screws. Unplugged electrical

connector which should be reconnected before new unit is screwed

back down.

Replacement part is not the same as the original. From what I read.

this part has been a problem with these washers.

>Put Pulley Cover back on.

>Reset washer upright.

>Reconnected water and power.

>Ran "CALIBRATION". In Diagnostic Test Mode, turned to "rinse"

light on and pushed "start" button.

>Ran "AUTOMATIC TEST". In Diagnostic Test Mode, turned to "spin"

light on and pushed "staet" button. Washer agitated in first cycle

- "sensing" and in "wash".

.

Washer has been working as it should and I a very happy with the results.

I must say that PartSelect Identified the bad part as the Shift Actuator right off from the symptoms I provided.

>Disconnect power and water - cold, hot and drain.

>Put washer on its side on a stand (low platform) to get to the bottom.

Better than than just laying front of washer on floor.

>Used a drop light to help see bottom.

>Removed Pulley Cover using nut driver - has 2 screws with nut

heads.

>Removed and replaced the Shift Actuator (part provided) using a

Phillips screw driver - 2 green screws. Unplugged electrical

connector which should be reconnected before new unit is screwed

back down.

Replacement part is not the same as the original. From what I read.

this part has been a problem with these washers.

>Put Pulley Cover back on.

>Reset washer upright.

>Reconnected water and power.

>Ran "CALIBRATION". In Diagnostic Test Mode, turned to "rinse"

light on and pushed "start" button.

>Ran "AUTOMATIC TEST". In Diagnostic Test Mode, turned to "spin"

light on and pushed "staet" button. Washer agitated in first cycle

- "sensing" and in "wash".

.

Washer has been working as it should and I a very happy with the results.

I must say that PartSelect Identified the bad part as the Shift Actuator right off from the symptoms I provided.

Parts Used:

-

Maxwell from RINGWOOD, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer would not spin on wash cycle

My daughter is the handy one in the family. She followed Steve's video installation steps and in an hour i was washing clothes.

Parts Used:

-

Kim from MOUNT UNION, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

When the washer goes into a spin cycle, I would hear an intermittent loud clattering noise. I think the clutch teeth above (the cup part that is spring loaded) and the belted pulley's teeth below are not fully seating on each other during the spin cycle.

W10721967 Splutch Cam Kit

Assuming the pulley nut was properly tightened at the factory. I think this problem occurs because of ever-so-slight rounding of the splutch cam teeth from the actuator engaging and disengaging over whatever time frame there is before a clattering noise develops.

When I took off the 13mm nut using the adjustable strap tool, it felt tight to me...Was it put on as tight as it should have been at the factory? Who knows. I don't have the torque specification of this nut on that plastic pulley.

Watch the videos to remove and replace the belt cover and belt, actuator and splutch cam kit.

Pay particular attention to tightening up the nut. I put the pulley on and hand-tightened the nut. I used the adjustable strap tool and before I tightened everything, I pushed up on the pulley to press against the spring pressure in order to mesh the teeth together. After the nut was tight, I repositioned the strap tool and gave it another go, further tightening it. You see earlier that day, I only tightened it up once because I thought it was good and tight. I put everything back and within a half-hour it was clattering again and I could loosen the nut I thought was tight by hand! I fooled myself. That's why I did it twice, and don't be afraid to give it a good second tightening effort. Two weeks now and the wife is currently very happy.

Assuming the pulley nut was properly tightened at the factory. I think this problem occurs because of ever-so-slight rounding of the splutch cam teeth from the actuator engaging and disengaging over whatever time frame there is before a clattering noise develops.

When I took off the 13mm nut using the adjustable strap tool, it felt tight to me...Was it put on as tight as it should have been at the factory? Who knows. I don't have the torque specification of this nut on that plastic pulley.

Watch the videos to remove and replace the belt cover and belt, actuator and splutch cam kit.

Pay particular attention to tightening up the nut. I put the pulley on and hand-tightened the nut. I used the adjustable strap tool and before I tightened everything, I pushed up on the pulley to press against the spring pressure in order to mesh the teeth together. After the nut was tight, I repositioned the strap tool and gave it another go, further tightening it. You see earlier that day, I only tightened it up once because I thought it was good and tight. I put everything back and within a half-hour it was clattering again and I could loosen the nut I thought was tight by hand! I fooled myself. That's why I did it twice, and don't be afraid to give it a good second tightening effort. Two weeks now and the wife is currently very happy.

Parts Used:

-

TERRY from WAUKEE, IA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Socket set

5 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer was draining but no spinning

Disconnect electrical plug from the wall, disconnect drain hoses and tip washer forward remove belt hosing basket and then remove the electrical plug that contains seven wires connected to actuator then remove the two small screws.

Then reverse the operation to stall the new part. Very easy.

Then reverse the operation to stall the new part. Very easy.

Parts Used:

-

JOSE from MILLBURY, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water would not stop running over filled the washer

Unplugged the washer turned off the water disconnected the water lines then took the cover off and disconnected the wires and took 2 screws out and took the old part out and put the new 1 in

Parts Used:

-

Mary from GROVER HILL, OH

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Had to replace the agitator

I already had the old agitator out, so when I got the new one I put it in the tub. You have to spin it a little so it seats properly. I then tightened the bolt with a 7/16” socket and my wife was washing a load within 15 minutes

Parts Used:

-

Thomas from MENTOR, OH

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The Agitator in my washing machine wasn't spinning, and was loose.

After researching and learning from the university of YouTube, I ordered new agitator 'dogs' from PartSelect - the rubbery dogs which look like gummy bears, were worn out in my machine and needed to be replaced. These dogs secure the inner part of the agitator. After watching several videos on YouTube, I knew precisely what to do and what I needed. I researched and found PartSelect on-line and they were very helpful and sending me the dogs. It was a very simple fix, and my washing machine now is working like brand new. Thanks PartSelect for all your help and will reach out again for any future self-fix projects!!

Parts Used:

-

Anton from BRONX, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!