LGA30AW (PLGA30AW) Amana Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Dryer shut down before clothes were dry

... I figured it was some over temp switch but then read about the gas solenoid problems others were having... bought $100.00 worth of parts... saved the old just in case down the road I might need them... figured a service call would cost me that much... now lots of new parts... and a working dryer. Done!

Parts Used:

-

Donald from Madison, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Socket set

21 of 30 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Screeching sound coming from back of the dryer.

First removed the bottom access panel, then the then pried the top lid open. Then, I could get to the four screws holding the front of the drum in place. Once that was removed, reached underneath drum and disconnected belt from tensioner pulley and motor. Removed the drum and discovered the problem. One of the two drum rollers had completely disintergrated from the shaft, actually "melting" off of its roller shaft. Removed both of the rollers and shafts by putting a flathead screwdriver on the slot of the shaft, and at the same time holding the locknut behind the bracket with a box wrench. I replaced both shafts and rollers and reused the same washers and snaprings. I used a screwdriver and a vice to remove the snap rings off of the old shafts. The best bet is to use a pair of snap ring pliers, which I didn't have. I used some white silicone grease to lube the new rollers up, reinstalled them and replaced the belt. You MUST route the belt around the drum before you install, then connect the belt to the motor underneath and wrap it around the tensioner. While I had everything opened up, I shop-vac"d the inside of my dryer(filthy). I did this before putting anything back together. Also, when re-installing the front dryer panel, make sure the motor inlet and the lint outlet tube form an airtight seal. All in all, this was a fairly strightforward job. The dryer now works great and is as quiet as a mouse.

Parts Used:

-

Brian from Yucaipa, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

16 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer making loud squeeking noises

The pully wheel was completely worn down as the belt had cut into it over time. I'm not sure if the lever and shaft needed replacing but since the part was inexpensive I decided to replace it as well as the wheel. The easiest way to access the parts was to turn the dryer on its side and remove the bottom panel of the dryer. This eliminated the need to remove the drum. It was then easy to reach in with a wrench and remove nut and bolt that held on the pulley lever. I also had to remove the spring which was attached to the lever. Next I put the new pully wheel on the shaft of the new pulley lever. The most difficult part of the job was installing retainer clip which holds the wheel on the shaft. This took a little persistance. After this was done it was simple to put the assembly back in place, reattach the spring and tighten the nut and bolt. I then replaced the bottom panel of he dryer, turned it upright and plugged it in. The whole job took just over an hour. One tip: Before removing the old assembly, I took a picture of it with my cell phone camera so I would remember how it went back together.

Parts Used:

-

James from North Kingstown, RI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Socket set, Wrench set

15 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer drum stopped spinning

Dryer drum stopped but all other elements seemed functional; couldn't afford new dryer. Unplugged appliance & moved it to my garage (more room to move about). Undid base plate w/tools and found belt slack - identified broken idler pully wheel as part to fix. Went online & found part-select, located part & was way happy: $7.00 part + $7.00 shipping; got part 3 days later. Removed broken pully wheel (take off lock-washer, put wheel on, reinstall lock washer). Cleaned out venting elements (huge lint-ball & some sand in blower intake area). Re-attahced base. Back on-line to see "replace dryer belt" instruction sequence; opened lid of machine (while verticle) and positioned belt properly. Located access port (sealed) at base, knocked out the circular metal plate so I could reach in & thread the dryer belt back around motor & idler pulley wheel. Did test spin (manually) to make sure belt properly threaded, in place. Move appliance back to proper location, plugged in & hooked up venting to outside; ran test & SUCCESS!!!! It even seemed to dry better because of the now cleaned venting area. Labor cost = $0, Part cost < $15.00, Time (actual work) bit over 3 hours total.

Parts Used:

-

Leif from Brighton, CO

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Socket set

15 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer not heat up

Pulled the front panel off and cleaned out all the lint out that had gotten past the lint screen. Pulled off the back panel for same. Removed lint roughly the size of an adult badger. Did not solve problem. Could see that the heating element was glowing red but gas was not igniting, very tempted to put out my cigarette. Between the assembly gas valves impotent clicking and the free trouble shooting info off the net... I guessed it was the gas valve assembly. Got the part from Part Select and replaced it. (part arrived much quicker than I thought it would too) Dryer now works and while I didn't need the thermostat, it was cheap enough that I will just keep it as it is the next likely part to take a hike.

Parts Used:

-

bill from Austin, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

17 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door Catch was broken

I just inserted the door catch, which by the way fit in perfectly. Thanks. Took 5 seconds to repair.

Parts Used:

-

Inocencio from Edinburg, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

14 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

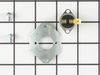

Time clock not moving .Not enough heat

Opened front panel .Tested both coils on gas valve.

Found no continuity on one of the coils. Replaced coil,

dryer works like new.

Found no continuity on one of the coils. Replaced coil,

dryer works like new.

Parts Used:

-

PHILIP from LONG ISLAND CITY, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

16 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner would not go on on my Stack Set Dryer

Took out two front Panel screws and removed the panel. Removed Gas solenoid coil holding bracket by removing two phillips head screws. Disconnected the coil leads. and removed the coils. Connected the new coils to the leads and set in place. Replaced the holding bracket and the two screws. Replaced the front cover and the two front cover screws. Piece of Cake!

Parts Used:

-

Robert from North East, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

16 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor would shut off in two or three minutes after starting.

I removed the dryer front and the drum, then disconnected the wires from the dryer motor and removed it from the motor mount, after installing the new motor in the motor mount the rest was just putting the dryer back together the same way I took it apart, the best way to do this is to print out the diagram from partsselect.com and follow it step by step, this was so easy everybody can do this and save alot of money for the labor and the parts mark-up, try it you all can do it (SO EASY)

Parts Used:

-

James I from Henderson, NV

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

13 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The Dryer would not get hot.

I removed the two screws holding the access panel, and removed the access panel. Then removed the lower air duct. I then checked the burner, The solenoid was not opeing the valve for the gas. I order the coils, in two day I had the coils and installed them. The dryer is working great.

Parts Used:

-

Jerry from Bradenton, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

14 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The dryer was not fully drying

After replaceing several parts including the thermostats the last part I replaced the coils were the defective part. I originally metered out the themostats and they appeared to be okay but since this was my first time I thought I might have been mistaken. It turns out the last part I thought it could be was the part that was defective. I will say that it is very simple to replace any of the parts involved. The hardest part was trying to open the dryer itself. But after having to do it 3 times, I'm now a pro. I also replaced the drum belt and since I had it open I also replaced the belf idler with a newer modified idler rolller.

Putting the belt back on is easy, but it helps to view the video or a picture to understand how the belt goes around it.

Putting the belt back on is easy, but it helps to view the video or a picture to understand how the belt goes around it.

Parts Used:

-

Michael from Chicago, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Socket set

12 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Switch did not turn off dryer when door opened

Switch can be removed from outside of dryer and your video described the repair as having to work from inside dryer. But since wires were still attached to old switch, it could be popped out and wires switched. Since there were three wires on new switch to allow it to turn on and off a circuit, it was useful to check the resistance of the switch compressed or released to be certain I was attaching the two wires to the right two poles of the new switch. But that all required only a couple of minutes. Thank you.

Parts Used:

-

paul from madison, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

13 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer not heating up

Unscrewed 4 screws,pulled off front of machine.Unscrewed 2 screws holding coils on,unplugged coils,installed new coils,plugged in coils,reinstalled 2 screws for hold down brace.Reinstalled front cover,plugged dryer into outlet(remember to unplugged dryer before working on it).started up,instant heat,works great.thanks Partselect for helping me out!!!

Parts Used:

-

Richard from New Windsor, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

12 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Gas Dryer would heat for one heating cycle but no gas afterward. Ignitor would glow.

Checked four thermocouples all showed continuity with my multimeter so they were all good. I'd read that the coils commonly went out and that these were the symptoms. Hey, it's very simple in there. Not much else could be wrong. I had a Maytag repairman come out. At first he said the problem was a blocked vent. I knew he was wrong. Then he said one of the thermocouples went out. It was $80 for him to come out. It turned out that his second diagnosis was wrong too. To repair the dryer by Maytag would have cost me $240. I gave him $80 and bought the coils for $37. They are EXTREMELY easy to replace: two screws held a bracket that held two coils. With the bracket off, I took off the old coils and slid on the new ones.

Parts Used:

-

Jim from Foothill Ranch, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Close would not get dry. Dryer started normal. Timer would not time out.

Getting to any of the parts in the Maytag dryer is easy. Tip the dryer back and slide a 4 x 4 block under the front edge. You remove the whole front panel after you remove two screws at the bottom corners of the front panel. You need to tip the dryer back to get a screwdriver on the screws. Swing the front panel up to release the top of the door panel from the top. Watch the short wires to the door switch. Unhook the door switch wires and move the front panel out of the way. The timer on the top is accessed by re-moving two screws along the top edge. There are four screws. Remove them all and tip the top of the front panel forward. You then see that two screws hold the panel and the other two screws just hold the trim.

The dryer started normal. The drum motor run when the start button was operated. The fluff cycle operated normal to indicate the timer motor was OK. On the dry cycles, the igniter heated up. The gas came on. The dryer run for some period of time and then the flame went off. The thought was that the low temp cycle thermostat sensed the dryer was hot and thus switched over to time the cycle to its end. However, the low temp cycle thermostat tested good with a meter when the sensor was removed from the dryer and heated with a light bulb. Burnt contacts in the sensor were a possible problem. I also though the radiant sensor may be bad and not recycling after it got hot. After time, the igniter would cycle on but the gas flame would not come on. I thought the radiant heater might not be tripping the secondary coil on the gas valve. The gas valve coils tested good. I was checking them cold after the dryer had cooled down. I ordered a number of parts.

I got lucky and did a test on the coils while the dryer was still hot. One of the coils in the dual booster holding coil was going open when hot. When cold it had enough continuity to let the gas valve cycle on once. After the coil got warm it went open and shut the gas valve off. When the coil did cool off, it again had continuity. I was about ready to trash the dryer when I finely found the problem. I am happy I persisted and worked the problem through to a solution. I purchased several extra sensors but saved money in the long-run. I rate this problem at the high end of complexity for the do-it your self home owner to solve. The problem was an easy fix once the real problem was found. Only 4 screws and 3 push on wire connectors (two were on the front panel for the door switch).

The dryer started normal. The drum motor run when the start button was operated. The fluff cycle operated normal to indicate the timer motor was OK. On the dry cycles, the igniter heated up. The gas came on. The dryer run for some period of time and then the flame went off. The thought was that the low temp cycle thermostat sensed the dryer was hot and thus switched over to time the cycle to its end. However, the low temp cycle thermostat tested good with a meter when the sensor was removed from the dryer and heated with a light bulb. Burnt contacts in the sensor were a possible problem. I also though the radiant sensor may be bad and not recycling after it got hot. After time, the igniter would cycle on but the gas flame would not come on. I thought the radiant heater might not be tripping the secondary coil on the gas valve. The gas valve coils tested good. I was checking them cold after the dryer had cooled down. I ordered a number of parts.

I got lucky and did a test on the coils while the dryer was still hot. One of the coils in the dual booster holding coil was going open when hot. When cold it had enough continuity to let the gas valve cycle on once. After the coil got warm it went open and shut the gas valve off. When the coil did cool off, it again had continuity. I was about ready to trash the dryer when I finely found the problem. I am happy I persisted and worked the problem through to a solution. I purchased several extra sensors but saved money in the long-run. I rate this problem at the high end of complexity for the do-it your self home owner to solve. The problem was an easy fix once the real problem was found. Only 4 screws and 3 push on wire connectors (two were on the front panel for the door switch).

Parts Used:

-

Roger from Westminster, SC

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

12 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!