LGA30AW (PLGA30AW) Amana Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Very noisy, stopped during cycle, would restart after a while but was getting worse.

I removed the front panels, lint screen, ductwork to fan, motor assembly, drum, drum rollers, and vent pipe to outside. I then cleaned years of accumulated lint and dust from the cabinet. Replaced the drum rollers, drum glide, idle pulley and motor assembly. The hardest part was getting my arm in to place the idle pulley onto the drive belt.

Parts Used:

-

Michael from Hill City, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

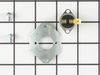

Coil replacement

Pulled out AC cord from wall socket first! Removed the dryer door and front panel (2 screws each) Then pulled both wire connectors off 2 coils. Removed hold -down bracket over coils. Replaced both coils and reconnect . No need to replace electronic igniter for gas. The right parts were shipped faster than I expected. Easy job. The Maytag repairman remained unemployed once again!

Parts Used:

-

Gregory from Morristown, NJ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

not heating

two screws on lint screen push up top two screws on front cover. two screws on coils lift coils off put back together. less than 10 minutes. all done

Parts Used:

-

James from Kingman, AZ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

dryer would heat on and off clothes not drying completely

Undo 2 screws take units out, clean a little, install new parts and screw down, done, great site !!!!!

Parts Used:

-

Donald B from Milwaukee, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Lost heat after a few minutes

Pried the top up, disconnected the door switch, removed two top screws holding the front panel, disconnected the spring and removed the front panel. Removed the screws and retainer holding the coils, replaced both coils and reversed the process. This was the third component I replaced to solve the problem....a cheap multi-meter and some testing would have solved the problem sooner. We now have the whole heat cycle.

Parts Used:

-

TONY from NEW EGYPT, NJ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Replaced belt, fronrt felt, glides

Not quite as show on your repair intructions. But, all in all not that difficult. Things went very well. However, in the midst of the repair I found I had to replace other worn out parts.

Parts Used:

-

Angel from Georgetown, DE

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

Was this instruction helpful to you?

Thank you for voting!

No heat after about 5 minutes.

Replaced all the sensors, the fuse and the set of coils.Now it is working like New.Parts arrived within 2 to 3 working days- excellent service.Will use Partsselect again when necessary.

Parts Used:

-

Asrat from Signal hill, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Socket set, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!

The dryer was not getting hot enough to advance timer

The repair went very smooth. I was able to follow the directions on partselect and had the repair done in 15 minutes. I took extra time to test the continuity on the ignitor and fuses. I also used the shop vac to clean out the inside of the dryer. The best part I liked about this web-site is the fact that once I described the problem I was told that the "M" series style coil was the fix 90% of the time! $27.70 including shipping was all it cost to make my clothes dryer work like it did the first day we got it!!

Parts Used:

-

Thomas from Buffalo, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Gas dryer wouldn't heat

Wouldn't have had a clue how to gain access to the coils without online instructions. It actually took longer to open the front of the unit than it did to replace the parts. Following the online instructions I removed two screws under the lint trap door. I then used a stiff putty knife under the left and right front corners of the lid to release the top, which I tilted back. Per the instructions I easily located the two screws releasing the front of the dryer. You have to lift the drum a bit to release the front panel. Once removed I was able to remove and replace the failing coils and then reversing the steps to put it all back together. An easy job and the dryer is back in shape.

Parts Used:

-

Bob from Manhattan Beach, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

No heat

-

charles from detroit, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

timer dot working/ heat not staying on

unscrewed the 2 screws holding the coil's in place took wires off one coil at a time tested coils with ohm meter found the two wire coil was bad replaced and scered the bracket that holds the coils back in place.PartSelect gave me a list of what was causing the problem and what the % of what was the cause,this helped alot Thankyou PartSelect

Parts Used:

-

Timothy from Burlington, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

The dryer failed to heat up

I'm a 65-year-old woman with no prior appliance repair experience. I learned on the web that 30% of the time, the failure-to-heat problem is caused by the valve coil, and 30% of the time, it's the cycling thermostat. So I ordered both parts. I watched installation videos on the web. The valve coil was accessable through a front port on the dryer so I started there. I had to go buy a stubby screwdriver because access to the screws was limited. From there, it was easy to take out the old valve coil and install the new one. Just 5 minutes. I plugged in the dryer again, turned it on, and it worked.

Parts Used:

-

Jane from Cohasset, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

would not tumble

I first unplugged the dreyer from the wall, I then used the putty knife to push clips in on top of the dreyer and opened the top. I used a nut driver to remove the front panel and unplugged the light and door switch wires. I then reached under the drum and removed the belt, and then lifted the drum out of the cabinet. I used snap ring pliers to remove the rollers and replaced.them with the new ones. After installing the new rollers I placed the new belt around the the.drum and lifted the drum by the belt placing it back into the cabinet. With the drum back in place I reattached the front panel and turned the drum to make sure it was not hanging up on the felt rings. With the drum moving freely and the belt hanging down I layed back in front of the dreyer and put the belt on the motor and reached up to.the tension pulley and placed the belt under the pulley. Once the belt had tension on it I again manually rotated the drum to make sure it wasn't binding anywhere. All was good so I replugged the light and door wires, shut the lid and plugged the dreyer back into the wall socket, turned it on and it worked great. From start to finish it took about.40 minutes and half that time was spent cleaning out the cabinet which had quite a bit of lint. I have used the.dreyer several times since the repair, and this completely took care of the problem. I highly recommend ordering the rollers along with the belt as mine were well worn and it saved me from having to take it apart twice. All in all a very eazy do it yourself project.

Parts Used:

-

DAVID from HIGHLANDS RANCH, CO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

Was this instruction helpful to you?

Thank you for voting!

Replaced pressure door switch

-

Robert from Dacula, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Idler pulley seized up, causing half of it to disintegrate and throw the belt

I would have been sick to have spent 100 bucks or more on a repair guy, or worse, several hundred on a new one. Six bucks and I'm back in action. I am only average handy, so anybody with a little talent can do this. I took the bottom front cover off first. Then opened the door and took the cover on the inside off. When you do this, you will have to disconnect wires from the door switch and inside light. Don't worry about it, they are pretty easy to remember what goes where, but if your scared, get little pieces of masking tape, write on it which connector it lands on, then tape it on the wire. The inside door cover will also take the vent and the connecting duct to the blower with it. You may have to wiggle the duct a little to get it off the blower. After that, I unfastened the top and lifted it back and out of the way. You should now be able to fully see the drum. No bolts, just slide it right out. If your belt is still around it, you may have to play with it a bit to get the tension off the belt. Once you got the drum out, you'll see the idler arm and pulley. I took the whole arm off (one nut and bolt) to make it easier to put the new pulley on. Once off, the hardest part of the job was to get the retaining ring off. If you got the right tool, it would be no sweat, but I didn't want to go to town, so I used two pairs of needle nose pliers to get it apart. New pulley slides right on, however, I would advise cleaning off any hardened grease on the idler arm connection and putting new grease on it. Put everything back together in reverse order. The belt can be a little tricky, but they have an awesome video on here, and once I watched it, had the belt on in 5 minutes. Buttoned everything back up just in time for kickoff. About an hour and a half work, less if I had the right tool to get the retaining ring off.

Parts Used:

-

Jeremy from Soddy Daisy, TN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Socket set, Wrench set

Was this instruction helpful to you?

Thank you for voting!