KUDS01FLSS1 KitchenAid Dishwasher - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Replaced Hinge Link

Pulled dishwasher from under counter, attached link to spring, hooked spring back into frame/chassis, threaded link through pulleys, attached other end of link onto door, reinstalled dishwasher under counter. All's well. Note-I purchased an extra link anticipating that the other one will fail. They're cheap enough.

Parts Used:

-

Scott from Fort Lauderdale, FL

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

622 of 661 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dishes on top rack of dishwasher were not being cleaned.

1) Remove top and bottom dish baskets from the dishwasher, this will give you room to work. To remove top basket there are clips at the end of the slide rails.

2) Remove lower spray arm by unscrewing plastic screw, it should only be hand tight.

3) In order to remove the strainer cover, you will need to remove the plastic tube that takes water to the middle and top spray arms. Unclip this tube from the top and middle clips and then work it out of the strainer assembly tube. Now you should be able to remove the tube at the bottom of the dishwasher by unscrewing it 1/4 turn.

4) Remove the strainer cover by unscrewing the 4 Torqs screws.

5) You will now see two smaller torqs screws that hold the hold the Chopper Assembly cover down. Take these two screws out and remove the two piece cover.

6) Pull out the broken Chopper Assembly, make sure you get all the pieces!

7) Install the new Chopper Assembly. Make sure that you install the Assembly with the small part of the screen towards the bottom of the housing. Also make sure you compress the spring as you install the part. I used a small pair of neddle nose pliers to compress the spring behind the screen in order to install the chopper assembly.

8) Put everything back together and make sure it works!

2) Remove lower spray arm by unscrewing plastic screw, it should only be hand tight.

3) In order to remove the strainer cover, you will need to remove the plastic tube that takes water to the middle and top spray arms. Unclip this tube from the top and middle clips and then work it out of the strainer assembly tube. Now you should be able to remove the tube at the bottom of the dishwasher by unscrewing it 1/4 turn.

4) Remove the strainer cover by unscrewing the 4 Torqs screws.

5) You will now see two smaller torqs screws that hold the hold the Chopper Assembly cover down. Take these two screws out and remove the two piece cover.

6) Pull out the broken Chopper Assembly, make sure you get all the pieces!

7) Install the new Chopper Assembly. Make sure that you install the Assembly with the small part of the screen towards the bottom of the housing. Also make sure you compress the spring as you install the part. I used a small pair of neddle nose pliers to compress the spring behind the screen in order to install the chopper assembly.

8) Put everything back together and make sure it works!

Parts Used:

-

Bill from North Richland Hills, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers

332 of 367 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud grinding noise from water pump

Rather than remove the pump assembly - as an earlier post had done - I pulled the entire dishwasher out and laid it down on the floor. This allowed easy, direct access to the motor (that was the hard, messy part). From this point it was easy. Unplug the wiring, remove the retaining bolt, rotate the motor off the mounting brackets and pull it out. Then put the new one in. That was the easy part (about 15 minutes). The entire job took 2-and-a-half hours, most of which was taken in disconnecting, cleaning up and reconnecting the dishwasher. It's much quieter now.

Parts Used:

-

Steve from Inver Grove Heights, MN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

219 of 245 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The old upper wash arm fell off.

I dropped the upper rack to its lowest position.

I pulled the upper water channel down from the spring clip [on the top of the washer] to get access to the hole on the top of the front end of the channel. The front end of the channel only drops an inch or two.

I put the new upper wash arm pivot [larger of the two small pieces] through the new upper washer arm from the bottom, placed the assembly up into the hole on the under side of the upper water channel, and snapped in the new keeper [smaller piece] through the hole in the top of the upper washer arm.

Finally, I snapped the upper water channel back into its spring clip. It was not even necessary to remove the racks.

There were no instructions or diagrams with the new parts, so it took me a few minutes to be sure which of the two small parts goes in from the bottom and which goes in from the top. Otherwise, I could have installed the new washer arm in one or two minutes.

I pulled the upper water channel down from the spring clip [on the top of the washer] to get access to the hole on the top of the front end of the channel. The front end of the channel only drops an inch or two.

I put the new upper wash arm pivot [larger of the two small pieces] through the new upper washer arm from the bottom, placed the assembly up into the hole on the under side of the upper water channel, and snapped in the new keeper [smaller piece] through the hole in the top of the upper washer arm.

Finally, I snapped the upper water channel back into its spring clip. It was not even necessary to remove the racks.

There were no instructions or diagrams with the new parts, so it took me a few minutes to be sure which of the two small parts goes in from the bottom and which goes in from the top. Otherwise, I could have installed the new washer arm in one or two minutes.

Parts Used:

-

Donald from Sunnyvale, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

173 of 181 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

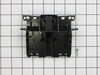

dispenser door was not closing

1. Remove torx screws around outer edge of inside of door.

2. Separate outer door panel from inner door panel.

3. Locate dispenser, and remove 6 hex nuts and 2 wires for solenoid.

4. Insert new dispenser and re-insert hex nuts.

5. Reinsert torx screws.

2. Separate outer door panel from inner door panel.

3. Locate dispenser, and remove 6 hex nuts and 2 wires for solenoid.

4. Insert new dispenser and re-insert hex nuts.

5. Reinsert torx screws.

Parts Used:

-

Ed from Fanwood, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

166 of 182 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dishwasher motor - making a very loud grinding noise

I went on the internet and found a pdf file with the Kitchenaid dishwasher repair manual for my model. One of the hardest parts of the job was convincing myself that I could do the job. When you're young, you just go out and buy a new dishwasher and tell yourself, "it's only money, we'll make more." When you're over 50, you tell yourself, "I can fix this. It will mean I get to retire a week sooner if I don't spend another $700 for a new dishwasher."

In hindsight, I could have done this job (replace the motor) in about 30 minutes. 1) Turn off electrical breaker in basement. 2) slide out dishwasher. 3) disconnect water supply. 4) use old towels to soak up any water still in the tub. 5) turn dishwasher on it's side. 6) unhook the wire harness plug from the motor, squeeze with fingers to unhook. 7) unbolt motor, 1 bolt. 8) turn motor counterclockwise, 1/4 turn. 9) pull motor out from sump, requires some force. 10) install new motor, but use some rinse aid to lubricate the rubber seal on it. Instead I did things the hard way and took the whole darn machine apart!!! See my story below.

I was surprised at how simple the design was and how few parts there really were inside the dishwasher. I found the pdf repair manual very useful, and I also found some repair videos on line. One thing they may or may not tell you - clean the parts well and lubricate the gaskets with some 'rinse aid' liquid when you put the machine back together. Also, it might help you to take a few pictures with a digital camera before you take things apart - that might help you remember how things go back together. Take close up pictures and use a treble light to illuminate the area when you're taking a picture.

The new motor was the ticket to fixing the loud noise. I was worried because the part cost $150. Before I ordered a new motor, I hooked up the old motor to electricity on my work bench and was able to recreate the really loud noise - so I was pretty sure that the new motor would eliminate the problem. It was very easy to install the new motor, only one bolt holds it in place. I did need to disassemble several parts to get to it though. Have no fear. One thing I did was mark the electric leads that went to the small pump with red and black sharpie markers so I could easily see which terminals to plug them back onto.

After reassembling the whole dishwasher with a new motor and testing the dishwasher for leaks by pouring a couple pitchers of water into it - I put the beast back under the counter (hooking it back up to the water supply line, the drain pipe to the garbage disposal and finally the electric supply). Then I ran it and water gushed out the bottom.

This whole job should have been easy, but things never go easy for me. Maybe if I would have lubricated the old sump gasket with rinse aid it would have sealed properly when I reinstalled it. Maybe if I would have cleaned the old sump gasket and the bottom of the tub really thoroughly things would have sealed right. But I didn't - so it leaked. I went ahead and bought a new sump gasket ($30 and had a few more days of waiting and self-doubt and having the dishwasher broken down). One the gasket came, I went through the entire uninstall, disassembly, reassembly and reinstall process AGAIN!!! This time with the new clean sump gasket and thoroughly cleaned surfaces. I also lubricated the gasket with rinse aid before installation. NO LEAKS! Job finished. Lessons learned. Doing it the first time was pretty tough though. Good luck! Get a helper for moral support and picture taking!

In hindsight, I could have done this job (replace the motor) in about 30 minutes. 1) Turn off electrical breaker in basement. 2) slide out dishwasher. 3) disconnect water supply. 4) use old towels to soak up any water still in the tub. 5) turn dishwasher on it's side. 6) unhook the wire harness plug from the motor, squeeze with fingers to unhook. 7) unbolt motor, 1 bolt. 8) turn motor counterclockwise, 1/4 turn. 9) pull motor out from sump, requires some force. 10) install new motor, but use some rinse aid to lubricate the rubber seal on it. Instead I did things the hard way and took the whole darn machine apart!!! See my story below.

I was surprised at how simple the design was and how few parts there really were inside the dishwasher. I found the pdf repair manual very useful, and I also found some repair videos on line. One thing they may or may not tell you - clean the parts well and lubricate the gaskets with some 'rinse aid' liquid when you put the machine back together. Also, it might help you to take a few pictures with a digital camera before you take things apart - that might help you remember how things go back together. Take close up pictures and use a treble light to illuminate the area when you're taking a picture.

The new motor was the ticket to fixing the loud noise. I was worried because the part cost $150. Before I ordered a new motor, I hooked up the old motor to electricity on my work bench and was able to recreate the really loud noise - so I was pretty sure that the new motor would eliminate the problem. It was very easy to install the new motor, only one bolt holds it in place. I did need to disassemble several parts to get to it though. Have no fear. One thing I did was mark the electric leads that went to the small pump with red and black sharpie markers so I could easily see which terminals to plug them back onto.

After reassembling the whole dishwasher with a new motor and testing the dishwasher for leaks by pouring a couple pitchers of water into it - I put the beast back under the counter (hooking it back up to the water supply line, the drain pipe to the garbage disposal and finally the electric supply). Then I ran it and water gushed out the bottom.

This whole job should have been easy, but things never go easy for me. Maybe if I would have lubricated the old sump gasket with rinse aid it would have sealed properly when I reinstalled it. Maybe if I would have cleaned the old sump gasket and the bottom of the tub really thoroughly things would have sealed right. But I didn't - so it leaked. I went ahead and bought a new sump gasket ($30 and had a few more days of waiting and self-doubt and having the dishwasher broken down). One the gasket came, I went through the entire uninstall, disassembly, reassembly and reinstall process AGAIN!!! This time with the new clean sump gasket and thoroughly cleaned surfaces. I also lubricated the gasket with rinse aid before installation. NO LEAKS! Job finished. Lessons learned. Doing it the first time was pretty tough though. Good luck! Get a helper for moral support and picture taking!

Parts Used:

-

Michael from St. Louis, MO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

148 of 152 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door spring link broken

1. Open the dishwasher and remove the two plastic grommets about halfway down on either side of the opening. Then remove the two screws under the grommets.

2. Remove the kick plate under the door. May have to lower unit by turning the feet using the adjustable wrench.

3. Make sure you have enough slack in the water input line and electrical wiring that you can pull the dishwasher out about 12 inches or more.

4. There is a spring and nylon rope link on both sides of the unit. Probably just one link is broken, but the replacement comes with two, so you can replace both or save one as a spare. Look at the good side and it should be pretty self explanatory how it attaches. I found it easiest to first thread the link around the lower pulley, then attach the link to the spring, then spring to the rear support, then the link to the door.

5. Reverse (2 to 1) to reinstall the dishwasher.

2. Remove the kick plate under the door. May have to lower unit by turning the feet using the adjustable wrench.

3. Make sure you have enough slack in the water input line and electrical wiring that you can pull the dishwasher out about 12 inches or more.

4. There is a spring and nylon rope link on both sides of the unit. Probably just one link is broken, but the replacement comes with two, so you can replace both or save one as a spare. Look at the good side and it should be pretty self explanatory how it attaches. I found it easiest to first thread the link around the lower pulley, then attach the link to the spring, then spring to the rear support, then the link to the door.

5. Reverse (2 to 1) to reinstall the dishwasher.

Parts Used:

-

Sean from Ramona, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench (Adjustable)

153 of 178 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The door would drop open when it was released

This was the second time I had this problem so I knew the symptoms and remedy. The tools needed were two nut drivers a ¼” and 5/16” along with a flat pry bar and Phillips screw driver. I started by removing the lower front panel by removing the two ¼” screws on either side. The lower panel will lift up and then can be removed by pulling on the bottom. There is a flat sheet metal piece behind the front panel with insulation that can be removed very easily along with the front panel. When the front panel is removed it exposes the front legs that may need to be dropped to let you lift the dishwasher over the tile (if you have ceramic tiles). The next step would be to remove any ties to the counter top if it is attached. Mine were attached by the two straps on either side with Phillips screws. After the top is free, lower the front legs by lifting the dishwasher with the flat pry bar and threading the legs up into their holders. With the legs lifted the dishwasher can be pulled out to expose the tension springs located along the sides at the very bottom. Chances are the ropes are broken off the plastic holders that fit over the door hooks.

Remove the plastic guides by removing the 5/16” nut from the middle of the lower roller. Remember to note which hole the screw is coming from this also sets the tension for how fast or slowly the door drops. Placing the nut closer to the front will drop the door slowly and toward the back will drop the door more quickly. I placed mine in the middle hole. When the plastic guides are removed attach the nylon pope to the spring and attach to the back of the dishwasher. There is a hole located on a flat piece of sheet metal the spring will attach to at the back of the dishwasher (if it is broken). Check the other side if it is still in tact. With the spring in place weave the rope around the plastic guides then pull the springs to help get the plastic end over the door hook located at the bottom of the door. Repeat this operation for the other side (kit has a both sides covered) and reinstall dishwasher in cabinet.

Steps

1) Remove front panel (1/4” nut)

2) Release Dishwasher from Cabinet

3) Lower front legs

4) Pull Dishwasher out from under Cabinet

5) Remove Rope Guide (5/16” nut)

6) Install new Rope Guide (Supplied in Kit)

7) Attach new rope to Spring and attach spring to dishwasher

8) Weave rope through rope guide

9) With door closed pull spring to relieve tension so rope can be attached to door

10) Repeat for other side (Kit has both sides)

Remove the plastic guides by removing the 5/16” nut from the middle of the lower roller. Remember to note which hole the screw is coming from this also sets the tension for how fast or slowly the door drops. Placing the nut closer to the front will drop the door slowly and toward the back will drop the door more quickly. I placed mine in the middle hole. When the plastic guides are removed attach the nylon pope to the spring and attach to the back of the dishwasher. There is a hole located on a flat piece of sheet metal the spring will attach to at the back of the dishwasher (if it is broken). Check the other side if it is still in tact. With the spring in place weave the rope around the plastic guides then pull the springs to help get the plastic end over the door hook located at the bottom of the door. Repeat this operation for the other side (kit has a both sides covered) and reinstall dishwasher in cabinet.

Steps

1) Remove front panel (1/4” nut)

2) Release Dishwasher from Cabinet

3) Lower front legs

4) Pull Dishwasher out from under Cabinet

5) Remove Rope Guide (5/16” nut)

6) Install new Rope Guide (Supplied in Kit)

7) Attach new rope to Spring and attach spring to dishwasher

8) Weave rope through rope guide

9) With door closed pull spring to relieve tension so rope can be attached to door

10) Repeat for other side (Kit has both sides)

Parts Used:

-

David from La Quinta, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

123 of 135 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

After removing our dishwasher from storage and installing it, the inlet valve was leaking.

After removing the kickplate covers from the bottom front of the dishwasher by removing the 2 screws that attached the covers I determined the inlet valve was leaking, I turned of the water and disconnected the electricity from the dishwasher.

I rolled the dishwasher from under the counter and removed the water supply line from the elbow at the bottom of the dishwasher inlet valve with an adjustable wrench. We then set the dishwasher on its back to gain easy access to the inlet valve.

To remove the inlet valve, Using a philips head screwdriver I removed the one screw holding the bracket and the valve was loose from the dishwasher. Then, two wires were removed from the valve by sliding the clips from the tabs on the valve. The hose that carries the water to the dishwasher was removed by squeezing the clamp with pliers and sliding it onto the hose and pulling the hose from the nipple.

With the valve removed from the dishwasher, the elbow for the supply line can be removed from the bottom of the old valve and installed on the new valve using teflon tape to seal the connection.

The new inlet valve was then installed by reversing the procedure.

Checked to make sure there are no leaks and the dishwasher was good as new.

I rolled the dishwasher from under the counter and removed the water supply line from the elbow at the bottom of the dishwasher inlet valve with an adjustable wrench. We then set the dishwasher on its back to gain easy access to the inlet valve.

To remove the inlet valve, Using a philips head screwdriver I removed the one screw holding the bracket and the valve was loose from the dishwasher. Then, two wires were removed from the valve by sliding the clips from the tabs on the valve. The hose that carries the water to the dishwasher was removed by squeezing the clamp with pliers and sliding it onto the hose and pulling the hose from the nipple.

With the valve removed from the dishwasher, the elbow for the supply line can be removed from the bottom of the old valve and installed on the new valve using teflon tape to seal the connection.

The new inlet valve was then installed by reversing the procedure.

Checked to make sure there are no leaks and the dishwasher was good as new.

Parts Used:

-

Claudia from Avella, PA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

91 of 100 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

latch pops open on door during cycle...

Replaced strike plate...but may not have needed it ...He used a screw under the front of the strike plate as a wedge to increase tension...He said this has happened to this model before and an old tech told him about this fix...

It must be a defect in the model that after a while the strike plate needs more tension..sent unopened ,unused parts back

It must be a defect in the model that after a while the strike plate needs more tension..sent unopened ,unused parts back

Parts Used:

-

Linda from Laguna Niguel, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

94 of 112 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Glasses in the top shelf had food bits - not rinsing well

The most difficult part of this was figuring out the problem was with the middle spray arm - that it was not spinning (and thus not rinsing the top dishes). I could spin it by hand fine - but if I watched its position while the machine was running (open/close the door) I saw it wasn't moving. I took out the top shelf (with spray arm attached) and connected it to the garden hose. I could see then that the arm was sagging and hitting the rear connection, preventing it from spinning. To replace I removed the plugs from the top shelf side-rails (bend the rail open with your thumb and tip the plugs out of the rail to the right for the left rail, to the left for the right rail. this is easier than pulling them out the end of the rail). Slide out the top shelf. Turn over, remove the phillips screw and pull off the manifold, and middle spray arm. Replace with the new parts. I also replaced the top spray arm (which was very loose, and probably not spraying well because it was so loose). For this I unclipped the top feed tube and pulled off the old sprayer. Put a towel in the bottom rack of the washer so you don't drop the little pieces into the pump below. The top spray arm simply snaps in with the two connectors (the pointy one attaches through the feed tube).

Parts Used:

-

Clifford from Centennial, CO

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

79 of 89 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dishwasher leaking

remove old seal, clean and dry the gap where the new seal will be installed. Apply adhessive, place new seal, then let dry for 24 hrs.

The hardest part was getting the seal, we first ordered from a sears parts store locally. They also told me that everything was included to install it, but they did not include the adhesive, they lost the order via ups and never notified me. I finally called them and they made me go back to the parts store for a refund. I then ordered on parts select and they had it in my hands in 3 days.

The hardest part was getting the seal, we first ordered from a sears parts store locally. They also told me that everything was included to install it, but they did not include the adhesive, they lost the order via ups and never notified me. I finally called them and they made me go back to the parts store for a refund. I then ordered on parts select and they had it in my hands in 3 days.

Parts Used:

-

Noelle from Tucker, GA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

84 of 108 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top rack not cleaning the dishes properly.

I first thought I may have a defective water feed tube that runs from the bottom of the dishwasher tub aolng the back to the top. This is what the top rack sprayer plugs into to get water.

This was easily replaced by uncliping the feed tube by the two clips, one on the top of the tub and one in the back. You then give the feed tube a twist clockwise about 45 degree (relative to the bottom of the dishwasher). This will remove the feed tube and bottom sprayer.

However, this didn't fix the issue.

I then replaced the pump/motor. This is done by uninstalling the dishwasher and flipping it onto it's back so you can look at the bottom of the dishwasher. There is an electrial connector on the right side that needs to be disconnected. The motor is help on by one bolt in the back and a socket wrench with extender will be needed to get to it. Once the bolt is removed, and motor needs to be twisted about 45 degress so it feels "loose". Then you need to pull straight down and the motor will come off.

Just reverse all the steps to install the new motor.

But that didn't fix the issue either.

Come to find out, the problem I was having was the grinder screen was so gummed up with paper, the grinder broke and water was not getting through the screen. Here is how you replace the grider (which was the true fix to the problem).

- Remove the feed tube like I listed above. You DO NOT need to uninstall your dishwasher.

- Use a Torx driver to remove the three visible bolts on the bottom of the washer tub.

- Pull up on the plastic piece you just removed the screws to remove it.

- Use a smaller sized Torx driver to remove the one screw from the Grinder plate. Once you have the screw off, use a pair of pliers to pull straight up on post sticking straight up on the grinder housing.

-You can now see the grinder. Pull the screen and grinder assembly out. If it is still intact, just clean it and replace it back into its groove. If it is in pieces, it is destroyed and buy a new one.

- Reverse all the steps to put the dish washer back together.

This screen that fits into the groove was jammed up with paper and was causing my my issues. Once I placed this the macine worked great.

This was easily replaced by uncliping the feed tube by the two clips, one on the top of the tub and one in the back. You then give the feed tube a twist clockwise about 45 degree (relative to the bottom of the dishwasher). This will remove the feed tube and bottom sprayer.

However, this didn't fix the issue.

I then replaced the pump/motor. This is done by uninstalling the dishwasher and flipping it onto it's back so you can look at the bottom of the dishwasher. There is an electrial connector on the right side that needs to be disconnected. The motor is help on by one bolt in the back and a socket wrench with extender will be needed to get to it. Once the bolt is removed, and motor needs to be twisted about 45 degress so it feels "loose". Then you need to pull straight down and the motor will come off.

Just reverse all the steps to install the new motor.

But that didn't fix the issue either.

Come to find out, the problem I was having was the grinder screen was so gummed up with paper, the grinder broke and water was not getting through the screen. Here is how you replace the grider (which was the true fix to the problem).

- Remove the feed tube like I listed above. You DO NOT need to uninstall your dishwasher.

- Use a Torx driver to remove the three visible bolts on the bottom of the washer tub.

- Pull up on the plastic piece you just removed the screws to remove it.

- Use a smaller sized Torx driver to remove the one screw from the Grinder plate. Once you have the screw off, use a pair of pliers to pull straight up on post sticking straight up on the grinder housing.

-You can now see the grinder. Pull the screen and grinder assembly out. If it is still intact, just clean it and replace it back into its groove. If it is in pieces, it is destroyed and buy a new one.

- Reverse all the steps to put the dish washer back together.

This screen that fits into the groove was jammed up with paper and was causing my my issues. Once I placed this the macine worked great.

Parts Used:

-

Ben from Lake Zurich, IL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench (Adjustable)

75 of 82 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leakage along bottom of door panel during wash/rinse

The air inlet strip has a flap and two smaller side flaps that seal the bottom of the inner door to the bottom pan that hold the water. The flaps don't form a watertight seal as they only serve to prevent the water surging during wash and rinse cycles from splashing out of the bottom pan onto the floor under the door. What I learned after dismantling the door is that the problem I was having with water dripping from the bottom of the bottom of the outer door was being caused by a loose upper round louvered vent and not he lower vent strip. If the lower vent strip were the problem, water would leak from the front lip of the bottom pan, which is located well behind the face of the front door panel.

Here's my recommendation on the lower vent srtip repair. Turn off the power to the unit at you breaker panel. The air inlet strip is fastened to the backside of the inner stainleess steel door panel. To access the screws the outer door panel must be removed. Open the door and remove the six torx head screws that fasten the outer door panel to the stainless steel inner door. Don't remove the two torx screws top dead center as they hold the door latch. After removing the screws, raise the door up to the nearly closed position. Lift up the outer door panel handle and door bottom to disengage the outer panel from the inner stainless door. The next part is a little tricky since the vent strip hex head screws are at he bottom of the stainless door panel, facing out with the door closed. The lip of the bottom stainless pan is high enough to make it a tight fit to access the screws. There is also a steel bracket that is a door stiffener and holds electrical wiring. I found removing the bracket held by a 1/4" hex head screw on each side made access to the vent strip scews easier. Lay flat on the floor. With a 3/16" nutdriver or socket wrench each of the five vent strip screws can be removed. It's a tight fit between the bottom lip and door bottom, but it can be done. Remove the old vent strip and attach the new one. Make sure it fits snugly into the slot. Best to have an extra pair of hands at this point to hold the stip securely in place while screws are reinserted from the opposite side. Reassemble everything in reverse order.

It was when I had the outer door panel off that I noticed my problem was water getting past the upper round louver vent seal and thus running down the inside of the outer panel. Simple fix was to remove and clean the scale residue from the parts and door. Then reassemble the vent and twitst tighten the vent to compress the rubber seal on the inside face of the door.

Here's my recommendation on the lower vent srtip repair. Turn off the power to the unit at you breaker panel. The air inlet strip is fastened to the backside of the inner stainleess steel door panel. To access the screws the outer door panel must be removed. Open the door and remove the six torx head screws that fasten the outer door panel to the stainless steel inner door. Don't remove the two torx screws top dead center as they hold the door latch. After removing the screws, raise the door up to the nearly closed position. Lift up the outer door panel handle and door bottom to disengage the outer panel from the inner stainless door. The next part is a little tricky since the vent strip hex head screws are at he bottom of the stainless door panel, facing out with the door closed. The lip of the bottom stainless pan is high enough to make it a tight fit to access the screws. There is also a steel bracket that is a door stiffener and holds electrical wiring. I found removing the bracket held by a 1/4" hex head screw on each side made access to the vent strip scews easier. Lay flat on the floor. With a 3/16" nutdriver or socket wrench each of the five vent strip screws can be removed. It's a tight fit between the bottom lip and door bottom, but it can be done. Remove the old vent strip and attach the new one. Make sure it fits snugly into the slot. Best to have an extra pair of hands at this point to hold the stip securely in place while screws are reinserted from the opposite side. Reassemble everything in reverse order.

It was when I had the outer door panel off that I noticed my problem was water getting past the upper round louver vent seal and thus running down the inside of the outer panel. Simple fix was to remove and clean the scale residue from the parts and door. Then reassemble the vent and twitst tighten the vent to compress the rubber seal on the inside face of the door.

Parts Used:

-

Carl from North Haven, CT

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

66 of 68 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dishwasher was not cleaning dishes.

SAFTY: Turn water off. Flip the circuit breaker.

PREPARE FOR REMOVAL: Unscrew / Remove kickplate. Disconnected water connect just behind the kickplate. Be ready with a couple of dishtowels. Pull the door down and remove any screws that go into the under part of your counter top. Jack the front legs screw down.

REMOVE: Gently pull the Dishwasher from under counter. Push the insulation flat against the side of the dishwasher about every six inches that you pull the dishwasher out to prevent it from snaggin on the cabinet face edges. Remove the baskets and spray arms. Careful not to damage the heating element.

NOTE: Here I noticed that the guy who installed the dishwasher kinked the copper line limiting the water into to my dishwasher. So my circulation pump/motor was probably running dry. I replaced with a flex type "dishwasher" hose that will easily coil up behind / underneath without kinking when I push back in. DO THE REPAIR RIGHT - DO IT YOURSELF!

REPAIR: I gently laid the dishwasher on it's side (cardboard underneath). I disconnected the power - 2 wires. Then, I only disconnect one wire harness, the sump tubing and the I thought I'd better remove the impeller that the sump tubing was connected to (it was only attached with one screw). Remove the 3 plastic clips around the pump/motor. Carefully push the pump into the dishwasher. DO NOT LET THE PUMP FALL AS IT MAY DAMAGE THE HEATING ELEMENT IN THE DISHWASHER! Push the new pump/motor in place until the seal is at least flush with the bottom. I used the back of a wood spoon. Don't pull on any part of the motor from the bottom or you'll break the thin aluminum casting. Just inserting the plastic clips back in place will pull the seal flush with the bottom again.

I was lucky. I simply removed the motor/pump, replaced it with the new motor/pump, and put everything back together in reverse. I put a little bit of silicone grease on the o-ring of the temperature probe. I happened to have some silicone grease because I also have a pool.

Done. It cost me $220 Vs. $550 quoted by Sears. That doesn't count the extra Sears would have charged my for repairing the kinked copper line. And you know they would've kinked it again. That only cost me $20 more and the flexible line couldn't have been easier to install. I could have done the whole thing for less but I opted to replace the pump/ motor together.

Getting it all done right, no leaks, no kinked line, keeping the dishwasher that matches the other appliances (VS. replacing it at $550 repair price), all less than 1/2 the price of a quoted repair - PRICELESS. - THANK YOU PART SELECT. DISCLAIMER: I have no affiliation with Part Select.

PREPARE FOR REMOVAL: Unscrew / Remove kickplate. Disconnected water connect just behind the kickplate. Be ready with a couple of dishtowels. Pull the door down and remove any screws that go into the under part of your counter top. Jack the front legs screw down.

REMOVE: Gently pull the Dishwasher from under counter. Push the insulation flat against the side of the dishwasher about every six inches that you pull the dishwasher out to prevent it from snaggin on the cabinet face edges. Remove the baskets and spray arms. Careful not to damage the heating element.

NOTE: Here I noticed that the guy who installed the dishwasher kinked the copper line limiting the water into to my dishwasher. So my circulation pump/motor was probably running dry. I replaced with a flex type "dishwasher" hose that will easily coil up behind / underneath without kinking when I push back in. DO THE REPAIR RIGHT - DO IT YOURSELF!

REPAIR: I gently laid the dishwasher on it's side (cardboard underneath). I disconnected the power - 2 wires. Then, I only disconnect one wire harness, the sump tubing and the I thought I'd better remove the impeller that the sump tubing was connected to (it was only attached with one screw). Remove the 3 plastic clips around the pump/motor. Carefully push the pump into the dishwasher. DO NOT LET THE PUMP FALL AS IT MAY DAMAGE THE HEATING ELEMENT IN THE DISHWASHER! Push the new pump/motor in place until the seal is at least flush with the bottom. I used the back of a wood spoon. Don't pull on any part of the motor from the bottom or you'll break the thin aluminum casting. Just inserting the plastic clips back in place will pull the seal flush with the bottom again.

I was lucky. I simply removed the motor/pump, replaced it with the new motor/pump, and put everything back together in reverse. I put a little bit of silicone grease on the o-ring of the temperature probe. I happened to have some silicone grease because I also have a pool.

Done. It cost me $220 Vs. $550 quoted by Sears. That doesn't count the extra Sears would have charged my for repairing the kinked copper line. And you know they would've kinked it again. That only cost me $20 more and the flexible line couldn't have been easier to install. I could have done the whole thing for less but I opted to replace the pump/ motor together.

Getting it all done right, no leaks, no kinked line, keeping the dishwasher that matches the other appliances (VS. replacing it at $550 repair price), all less than 1/2 the price of a quoted repair - PRICELESS. - THANK YOU PART SELECT. DISCLAIMER: I have no affiliation with Part Select.

Parts Used:

-

Geoffrey from Indianapolis, IN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Wrench (Adjustable), Wrench set

66 of 69 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!