JJTF8500XLP3 Whirlpool Trash Compactor - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Compactor would not return to starting position

Like others who experienced this problem, I removed compactor from under the counter and laid it on its side. I removed the screws holding the cover plates to the motor and gear/chain box. The larger (4" +/-) plastic drive gear which moves the chain that lowers or raises the compactor ram was broke. Using a socket and ratchet, I turned the shaft the gear was attached to in a counterclockwise direction and moved the compacting ram from the bottom position to the top so I could finally open the door, It takes a lot of turns to move the compacting ram to the top so be patient. I then loosened the bolts, in the base, that holds the motor secure and slid the base toward the broken gear putting slack in the chain. I removed the split ring from the shaft and removed the sprocket which originally is part of the gear but was left on the shaft when the gear broke in three places. I elected to not remove the original washer and spacer and put the new gear with sprocket on the shaft, put the chain on the socket and installed the split ring. Slid the motor base back to original position putting slight tension on chain and a proper clearance between the gear and drive shaft (sheet of paper seperation). Reinstalled the covers, tested and was finished.

Parts Used:

-

Alan from Gillette, WY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Trash plunger would go down but not back up

Compactor ram would go to bottom but not return back up after compaction. Keep running until unplugged. After unplugging flipped unit on its side and remover bottom plate (5) nut screws, exposing gears. Found that the main large gear had fine crack which caused it to spin loosely. Ordered gear assembly and lossened four mount screw on motor to move it forward and give slack on chain. Hint: Loosen motor mount bolts, DO NOT REMOVE bolts COMPLETELY! Removed broken plastic gear and reassembled with new. Held/ pushed motor back to retention chain and secured four (4) mount bolts Then reassembled bottom plate with screw nuts and it worked perfectly!!

Parts Used:

-

Mark from Westport, MA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

compactor wouldn't shut off

-

Ray from Dallas, GA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Masher would no longer break glass bottles, and would keep running making a bumping sound

I removed the unit from under the counter. After removing all of the bits of old trash and making sure the chain and gears were not slipping or striped, I knew it was the power nuts on top of the ram. After all of these years they were worn out, almost smooth inside where the threads are. They were easy to locate on your website. I received them in 2 days (faster than expected) and in 10 minutes the unit was back together and working well. Today was the first bag to be taken out after the repair, it is much heavier than the previous ones, a sign that we are now packing much more trash in a single bag!

Parts Used:

-

Michael from Cullman, AL

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The compactor rubber guard was torn.

Removed 4 screws and the foot release to attach the new guard. Replaced the foot pedal and 4 screws and was done.

Parts Used:

-

Judith V from Studio City, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Compactor ram would not return to the top. The threaded bushings had broken off the wings that held them in place, causing them to spin.

I held up on the compactor ram as i loosened the two screws on each of the two retaining cups. I then unscrewed the threaded bushings and lifted the ram out of the unit. I then cleaned the surface of the tracks on which the ram guides up and down and applied a thin layer of silicone grease to those surfaces as well as the threaded rods. . I placed the ram back into the unit and held it in place as i replaced the threaded bushings and their respective caps. Unfortunately i neglected to move the limiting switch that stops the ram when it reaches the top of the cycle and I broke the lever that contacts the ram and subsequently activates the stop switch. so i removed the ram and removed and inspected the switch. It was broken beyond repair so i ordered a new switch from the same place I purchased the threaded bushings and am waiting for them to arrive. Lesson learned, pay attention to the sequence by which the original parts are removed and understand how the system functions so that you can remember to put it back in the right order.

Parts Used:

-

John from Templeton, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

ram wouldn't go up or down.

pulled it out, turned it upside down, and removed the gear, then replaced it, turned it back up and pushed it back it worked.

Parts Used:

-

Mona from San Diego, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench set

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Compactor piston stuck in down position and couldn't open!!!

First thing I did was put the unit on its side and removed the bottom to access the broken plastic gear that moves the chain that drives the compactor up and down...There I was able to manually move the chain by turning the nut with pliers and moving the piston up (painfully slow) until I could at least use the bin for trash while I waited for the replacement part to arrive. Once I had the part I loosened the four bolts that allowed the drive gear to move a little and slacken the chain - I then put in the new gear - make sure you have the proper spacing and washers - my replacement kit didn't have any washers so I resused the old washers and all seems to be working well!

Parts Used:

-

George from Houston, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Bad gears and a bad switch

-

John from ALICE, TX

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Wrench (Adjustable)

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

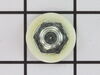

Roller was flat

Bought wrong roller. The drawer roller is different than the stationary rollers. Note the difference.

Parts Used:

-

John from Lancaster, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Wrench set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Compactor draw was not opening fully as the wheel bearings had seized

I followed the you tube video instructions provided by customer care. This involved pulling the unit free from the cabinet, removing several screws that held the housing in place, this gave access to the wheel assembly, then I removed the nuts that held the wheel assembly in place. Fitting the new wheel assemblies was easy as was replacing the housing screws. After reinserting the draw and pushing the unit back into the cabinet it worked like new

Parts Used:

-

Andrew from ASHEVILLE, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Trash Compactor ram will not move while motor running, stripped power nuts

Move the unit out of the cabinet, and take off the top cover.The two drive screws are easy to see. unscrew the two screws of one of the power nut covers and remove that cover. With pliers, unscrew the plastic power nut from that screw. Screw on the replacement power nut with the help of pliers and some heavy grease. install the bearing cap. Use the same procedure for replacing the plastic power nut on the other screw. To make sure the piston is level, place the cover on the power screw but do not attach it. Measure from the end of the screw to the top of the cover of the first screw, then adjust the second power nut up or down so the two power screw nut covers are the same distance down from the top of the it's power screw Lift up the piton assembly to close the gap, if any (I used a short piece of rope) , and install the screws on the second power bearing cap. After installation. recheck the distance from the top of the power screws to the power bearing caps is close to the same distance so the piston will be level.. This same procedure could be followed for other brands. Power of the appliance and verify functionality, if OK replace the top cover and push unit back into the cabinet..

Parts Used:

-

Raymond from TACOMA, WA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My very old trash compactor's carrier bag wore out

This new one from part select I think fit better than the original so all I had to do was install the handles as the depiction on the packaging showed and install it. Less than 1 minute.

Parts Used:

-

Jerry from CLARKSTON, WA

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rotary switch had finally worn out and was brittle and broken on our 30 plus year old trash compactor.

Removed the switch knob, the outer nut, and the front plate.

Unplugged the old switch from the 3 wires and plugged them into the new switch and put it back together with the new knob. Probably less than 5 minutes.

Unplugged the old switch from the 3 wires and plugged them into the new switch and put it back together with the new knob. Probably less than 5 minutes.

Parts Used:

-

Ray from MUNCIE, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Trash carier wore out

Upon the receipt of my part it just had to be slipped into place. I had the part I needed within 3 days of ordering.

My had ordered parts for various items in the past and we have always been very satisfied with the care and experteis of this company.

My had ordered parts for various items in the past and we have always been very satisfied with the care and experteis of this company.

Parts Used:

-

Carmen M from Port Orchard, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!