C228W Jenn-Air Cooktop - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

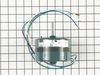

Downdraft Motor Bearings Shot

I first had to purchase the replacement motor which was quoted from a high of $236 to a low at graingers of$100. 00. The counterman at graingers removed the blower fan from the motor for me with a special long handled allen key. I then degreased and cleaned the blower fan. I had to cut off the screws on the motor and replace the 3 motor isolators and the urethane foam around the motor. I had to thread the 3 wires from the new motor through the bx cable from the old motor and reattach the fan to the motor. Anyone wanting more detailed informatioin may contact me at:mablume@optonline. Net

Parts Used:

-

MICHAEL from LAKE GROVE, NY

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

burner would only get super hot. could not control temp.

removed 4 screws holding burner controls. removed wires off old and placed on new burner control. very pleased with quick shippig of part. two days and range was as good as new. excellent company to buy from

Parts Used:

-

Thomas from Exeter, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Reusable Grease filter was old and worn out.

The Model number could no longer be read clearly on the stove electric grill with a down draft vent system, so all I had was the size and looks of the old grease/air filter. I was very happy to come across Parts Select by way of an amazon.com search. Their web site's design and the parts pictures with detailed descriptions made it easy to find exactly what I needed. The grease filter fit perfectly in no time. I have successfully used my cooking grill again.

Parts Used:

-

Gloria from Galveston, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

drain jar lids rusted and broken of their mounts

The lids are fastened to the underside of the unit by rivets....3 to each lid.

I used a cordless drill and small drill bit to drill through the rivets to remove the old lids and remains of the rivets.

The new lids are easily fastened back using a rivet gun ( about $20 in Lowes) using small 1/8th aluminum rivets.

No real problems.

1 thing to note is that the drill bit will pass through the old rivet by about 1/4 inch before it comes up against the upper level of the BBQ floor so do not drill any deeper.The aluminum rivets are easy to drill through and you will easily feel when the rivet is drilled through.

I used a cordless drill and small drill bit to drill through the rivets to remove the old lids and remains of the rivets.

The new lids are easily fastened back using a rivet gun ( about $20 in Lowes) using small 1/8th aluminum rivets.

No real problems.

1 thing to note is that the drill bit will pass through the old rivet by about 1/4 inch before it comes up against the upper level of the BBQ floor so do not drill any deeper.The aluminum rivets are easy to drill through and you will easily feel when the rivet is drilled through.

Parts Used:

-

ronald from ESTERO, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor bearing failure after 34 years.

Important: Down load the helpful assembly diagram for the fan motor and study it for a few minutes. It's very straight forward. Also a good idea is to remove the bottom panel which comes off easy before starting.

My only problem was removing the existing blower/fan wheel without damaging it once I had the assembly on the work bench. It was rusted on tight and managed to remove after a few tries using penetrating oil. The wheel is in stock and I'd suggest buying a new one along with the new motor if I had to do the job again.

Bottom line; the fan motor fit perfect but did have to re-use part of the old existing electric pig tail because the motor does not come with the factory type motor terminal connectors. By using three twist on wire connectors was back in business. The down draft vent works like new.

Wife is happy...

Wade

My only problem was removing the existing blower/fan wheel without damaging it once I had the assembly on the work bench. It was rusted on tight and managed to remove after a few tries using penetrating oil. The wheel is in stock and I'd suggest buying a new one along with the new motor if I had to do the job again.

Bottom line; the fan motor fit perfect but did have to re-use part of the old existing electric pig tail because the motor does not come with the factory type motor terminal connectors. By using three twist on wire connectors was back in business. The down draft vent works like new.

Wife is happy...

Wade

Parts Used:

-

Wade from CARMINE, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken switch

Took the (6) screws holding the top of the stove out, then removed the switch screws(2). Then lifted the top, so as I could reach and get at the switch. And then I repeated the above. It was alot easier the second time. Duh I erred the first time and replaced the wrong one and before I relized it, I opened the switch to check out. All in all. I still got satisfaction from doing it myself. Thanks Parts Select

Parts Used:

-

Al from Monroe Twp, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

high blower vibration

blower wheel was caked with dried grease clumps; replaced blower wheel, urethan foam and 3 motor isolators; blower/fan no longer vibrating cooktop.

Parts Used:

-

Lawrence from Chandler, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

9 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner switch on stove top burned out

First I turned off the circuit breaker at the control panel to my Jenn-Air stove-top. At 220-volts, don't take any chances with electricity!

Then I removed two screws that hold the burner switch panel in place and lifted up the panel to expose the wires that are connected to all 4 of the burner switches, the exhaust fan and pilot lights that indicate if a burner is turned on.

I used a circuit tester to determine that the power was indeed off to the switches. Again, it is extremely important to respect 220-volts of electricity.

I ensured that all of the wires were already labeled the same as the terminal connections on the switch (i.e. H-1, H-2, P, etc.). If they are not, label them yourself with masking tape around each wire. Then I removed each of the wires connected to the burned out switch with a pair of needle-nose pliers.

Next I removed the two screws attaching the burner switch to the panel.

To install the new switch, repeat all of these directions in reverse, making sure to attach each labeled wire to the correct terminal on the burner switch.

Turn the circuit back on at the circuit breaker. Then test the burner switch and see if the burner heats up. Hopefully, you'll be cooking in no time...............

Then I removed two screws that hold the burner switch panel in place and lifted up the panel to expose the wires that are connected to all 4 of the burner switches, the exhaust fan and pilot lights that indicate if a burner is turned on.

I used a circuit tester to determine that the power was indeed off to the switches. Again, it is extremely important to respect 220-volts of electricity.

I ensured that all of the wires were already labeled the same as the terminal connections on the switch (i.e. H-1, H-2, P, etc.). If they are not, label them yourself with masking tape around each wire. Then I removed each of the wires connected to the burned out switch with a pair of needle-nose pliers.

Next I removed the two screws attaching the burner switch to the panel.

To install the new switch, repeat all of these directions in reverse, making sure to attach each labeled wire to the correct terminal on the burner switch.

Turn the circuit back on at the circuit breaker. Then test the burner switch and see if the burner heats up. Hopefully, you'll be cooking in no time...............

Parts Used:

-

Tom from Lenexa, KS

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

burner would not get hot, switch did not feel right

It would have been nice if basic instructions were supplied ( eg. how to remove switch panel ) but it went rather smoothly.

First killed power the electric stove.

I then removed the screws from the bottom of the panel and then pried the top of the control panel down and then out. I copied the positioning and wire colors.Removed wires from prongs, removed the two screws, replaced old switch with new one .

First killed power the electric stove.

I then removed the screws from the bottom of the panel and then pried the top of the control panel down and then out. I copied the positioning and wire colors.Removed wires from prongs, removed the two screws, replaced old switch with new one .

Parts Used:

-

Richard from Howell, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Front element would not turn on

I removed the 4 screws that held on the front panel as well as the knob of the defective switch. With the panel free, I pulled the wire connections from the rear of the switch with needle-nose pliers. I then removed the 2 screws which secured the switch and removed it. I then reversed the process with the new switch. It could not have been easier.

Parts Used:

-

Arthur from Cardinal, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner got excessively hotand couldn't be regulated

The hardest part was breaking the caulk seal between the range and the cabinet. An extra set of hands made the job easier, by holding the panel while I connected the switch. The switch was delivered promptly and I am very happy with Parts Select. I found the other repair stories very helpful.

Parts Used:

-

Vernon from Wells, ME

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Nearly 29 year old grill element was broken and not heating properly.

Unplugged and removed the old grill element by hand and installed the replacement element by plugging it into the socket. Tools were not required for this and it took less than five minutes. The new element is great and heats much better than the original did before it broke.

Parts Used:

-

Robert from Venice, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Element failed

-

Andrew from Salem, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

smell of a dead animal

The 15-year-old Jen-Air stove started smelling really bad. I thought it was a dead animal stuck in the exhaust tube which runs under the floor to the outside. I flushed it out with clorine bleach, but it was still bad. It turned out to the be the grease filter. I washed it every week in the diswasher, but it just was not enough to get it clean enough. Finally, the grease went rancid and smelled really bad. This "repair" took about 30 seconds.

Parts Used:

-

Duane from Niceville, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

remove burned switch and replace

Truned off power at circuit breaker box. Removed two screws to access the control panel wiring. Removed several connections to allow to pull wiring harness out for access. Removed lock nuts with combination of needle nose pliers and box wrenches. (it was difficult to find a size fit since nuts were distorted. Pulled old switch out. Inserted new one and new lock nuts. Reconnected loose wires and replaced housing. Turned on power and tested. All was well.

Parts Used:

-

paul from Morgantown, WV

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Wrench set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!