ATF6500GG1 Frigidaire Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

belt was still on washer, had developed a loose tear

Very easy to replace belt on this model, belt had spilt and the loose rubber was flopping around and dislodged plug from water pump. Washer would not start cycle, display showed (no spin). Removed back access panel with screwdriver. Spin the pulley and slip belt off pulleys. New belt is very tight but it will go on, no tension adjustment on this model. Thanks part select quick service will order again from this company.

Parts Used:

-

jeffrey from mount juliet, TN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

7 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The front level screw legs are made of plastic and each time I move they break

-

Bobby from Asheboro, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Wrench (Adjustable)

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

One of the wash tub shock absorbers broke.

I heard that the repair job was simple and the part was not expensive (whew!) The repair video on your website was MOST helpful and gave me confidence. At first I tried it exactly as the guy demonstrated and all went well removing the broken support. Installing the new one (on the right side) was impossible for me. I could not get good enough leverage to fully re-insert the lock pins and I was slicing up my arm on the sharp metal edges. I removed the 900+ screws (just kidding- but there were quite a few) from the back panel and could access the lock pins MUCH easier. All four for both shock absorbers snapped right in. Re-attaching the rubber vent hose involved a few cuss words but I got it back on correctly after taking a break. All is great with the little washing machine once again! Thank you for the installation video and amazingly fast shipping, wow.

Parts Used:

-

Joshuah from Indianapolis, IN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

6 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud humming noise from the door closure area.

First,turned the power and water off. I disassembled the door lock and switch assembly by removing two screws from the rear of the top lid to gain access to the switch. Removed two screws from the switch assembly located in the front door latch area. With screws removed, I seperated the three terminal blocks and inspected the assembly for failure potential. Discovered a small crack in the switch housing which created error in relay function. Ordered the part and installed in reverse order of above. Realigned the door for proper closing, turned water and power on and did laundry all night to catch up!!!

Parts Used:

-

Alyre from Van Buren, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

6 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer Door Wouldn't Lock

I watched the u-tube video and followed what he did and it was fixed. Reason it took over 15 min I had to find the correct bit for the screw. I think your web site is great thanks

Parts Used:

-

Shawn from Springdale, AR

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

6 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer wouldn't enter the spin cycle. Clothes wet at end of wash cycle.

Open the door. Pull the clamp off of the boot (locate spring at bottom). Peel back the boot on the right side so that you can get to the door lock and switch assy. Remove the 2 screws in the front that hold in the door lock and switch assy. Remove the wires from the old assy. Transfer the wires to the new assy. Screw in the new assy. Refit the boot and clamp. give it a try.

Parts Used:

-

Leslie from Tolland, CT

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Both shock absorbers for the tumbler had broken off

The repair itself was simple; it was the original design of the washer itself that made it time-consuming, because of the tight spaces involved. Basically, all you have to do is remove 2 plastic pins, take out the broken part, make sure you have the new part facing the right way, and put the 2 plastic pins back in. Should take 2 minutes if there are not other machine parts in the way!

Parts Used:

-

Elizabeth from Bellevue, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

crack in plastic housing

first removed top of machine. removed 3 valve core wires set. Then removed left top screw on valve. Then removed vent tube to get to lower right screw. disconnected hose connect rack so valve housing could be removed & new installed. Rapped insulation around valve & installed. Put everything back together in reverse order.

Parts Used:

-

Jim from Tucson, AZ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

It would not start

I unplugged it from the outlet, undid the two screws from the top, then slid it off, opened the door and undid the two screws from the door switch lifted it out relaced it with the new one, screwed it back into place, replaced the top, plugged it back in and away it went.

Garry

Garry

Parts Used:

-

Garry from Burlington, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

7 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door hinge bottom bushing broke - Door latch no longer lined up with catch

First, I recommend you have a second pair of hands. The chrome door is quite heavy. Using Phillips screwdriver I removed the screws that attached the door to the frame. I had a helper hold the door while I removed the screws.

Once hinge screws were removed I put a towel down on a counter to keep the front of the door from getting marked up and proceeded to remove all of the screws around the back of the door so that I could lift the frame up enough to remove the broken hinge and insert the new hinge. It was a bit tricky to get the new hinge with bushings in place. I gently lifted the frame up with a flat head screw driver to widen the opening so I could get the bushings on the new hinge into position on the frame. Make sure they are properly inserted before you start tightening up screws.

Next, replaced all the screws on the frame, returned to the washing machine with helper who held the door up while I aligned the holes in the new hinge to the holes in the frame around the opening to the washer.

After everything was secured and tightened, to my surprise, the door latch did NOT line up with catch without lifting up about a 1/4" or a little more, on the bottom of the door. If someone slams the door without doing that you could break off part of the plastic latch or damage the catch inside the door frame.

I believe the original holes on the door frame were not drilled precisely during the manufacturing process and that is why the bottom bushing broke. We have always had to lift up a bit on the door to line up the latch with the catch. Eventually the strain on the bottom bushing caused it to break and then the door tilted down so you had to lift it up about 3/4 inch to latch it. I bought new hinge because if the top bushing broke the door could have come off.

Next time I buy a washing machine, I will pay more attention to the line up of the door latch with the door catch.

Flashlight helped me line up the holes.

Once hinge screws were removed I put a towel down on a counter to keep the front of the door from getting marked up and proceeded to remove all of the screws around the back of the door so that I could lift the frame up enough to remove the broken hinge and insert the new hinge. It was a bit tricky to get the new hinge with bushings in place. I gently lifted the frame up with a flat head screw driver to widen the opening so I could get the bushings on the new hinge into position on the frame. Make sure they are properly inserted before you start tightening up screws.

Next, replaced all the screws on the frame, returned to the washing machine with helper who held the door up while I aligned the holes in the new hinge to the holes in the frame around the opening to the washer.

After everything was secured and tightened, to my surprise, the door latch did NOT line up with catch without lifting up about a 1/4" or a little more, on the bottom of the door. If someone slams the door without doing that you could break off part of the plastic latch or damage the catch inside the door frame.

I believe the original holes on the door frame were not drilled precisely during the manufacturing process and that is why the bottom bushing broke. We have always had to lift up a bit on the door to line up the latch with the catch. Eventually the strain on the bottom bushing caused it to break and then the door tilted down so you had to lift it up about 3/4 inch to latch it. I bought new hinge because if the top bushing broke the door could have come off.

Next time I buy a washing machine, I will pay more attention to the line up of the door latch with the door catch.

Flashlight helped me line up the holes.

Parts Used:

-

John from Dover, NH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would drain, but not spin

I had called a repair man; and fortunately he never returned my call. After reading many of the reviews involved with the same problem, and wanting to use my washer, I decided it was easy enough to give it a try. And so it was. 2 screws in back removed the cover; and 2 screws in the front of the washer permitted the removal of the affected part. Removed three "plugs" from old; put them on the new part; replaced it back in the washer, and replaced the two front screws, which held it in place. Replaced top, securing with the two screws. And surprise - surprise -- the washing machine was working again! Your reviews were so helpful and encouraging --- that this really old lady decided to try it --- and like they all said "It was really easy to fix."

Parts Used:

-

Eleanor from Jekyll Island, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Basket loose and banging around - both shocks broken

-Unplug machine and remove all water connections

-Remove back panel with power phillips screwdriver

-Removed some rectangular circuit box in the way of getting to one shock absorber (3 screws)

-Remove old shock absorbers with 1/2 inch socket (suggested in accompanying directions)- this took 2 minutes

-inserted new shocks as directed...this was the most difficult part, but used a hammer to bang into place.

-reinsert and screw down circuit box (or whatever it was)

-reattach back panel

-reestablish water hose connections

-plugged in and was in business

-had ordered a washer/dryer set for $1700 (at my parent's urging) and now can tell Sears to go pound sand!

-Remove back panel with power phillips screwdriver

-Removed some rectangular circuit box in the way of getting to one shock absorber (3 screws)

-Remove old shock absorbers with 1/2 inch socket (suggested in accompanying directions)- this took 2 minutes

-inserted new shocks as directed...this was the most difficult part, but used a hammer to bang into place.

-reinsert and screw down circuit box (or whatever it was)

-reattach back panel

-reestablish water hose connections

-plugged in and was in business

-had ordered a washer/dryer set for $1700 (at my parent's urging) and now can tell Sears to go pound sand!

Parts Used:

-

Christopher from Woodbury, CT

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken / Loose Vane

Removed broken Vane and reinstalled replacemnet real time repair 2 minutes. It took longer to open box than to fix.

Parts Used:

-

Gary from Grand Junction, CO

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Glass broken

By unscrew the washer Machine door off' then place the door flat surface and start to unscrewed each screw carefully keep all the screws together then remove the broken glass that you don't cut yourself in a safe place, then place the New glass back on & replaced all the screws back on tightly once all the screws back in then replaced it back on to the washer Machine, make sure you pre-test your washer Machine for no leaks.

Parts Used:

-

Lillian from PHILADELPHIA, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

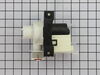

Pump motor made humming noise and wouldn't drain water from tub.

Disconnect power. Disconnect water hoses. Remove back panel. Remove top panel. Disconnect bladder ring. Disconnect control panel wire harness and control panel. Remove front panel. Disconnect hose clamps to drain hose and tub drain hose. Disconnect pump motor power supply wire. Disconnect pump screws. Now do everything in reverse replacing old pump with new.. One special note: replace factory hose clamps with new hose clamps.

Parts Used:

-

Matthew from Oakford, IL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!