A101 - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

washer was leaking when water level got about 4 inches in tub

It was fairly easy, start out by using a screwdriver and push down and out on the front cover and remove it. Take out the 2 small bolts that hold the top cover down to the sides and lift the top cover up and lean it back out of your way. On the bottom side of the agitator there is a small bolt that holds it down, loosen that bolt and pull the agitator out. The hardest part of the entire jod was to use a small chisel and hammer to take off the nut that holds the assembly down.Remember it has reverse threads,you have to use a chisel to back it off and use some WD40 to help remove the calsium build up that is around it. Once you get that large nut off, there is a set screw on the side of the assembly that you have to loosen up before you can take it off, it's a "star driver" head and not a allen wrench set screw.Just take your time and look at your new part and compare it with the old one and take your time and remember how you take the old part off,and you will not have any problem putting the new one on. This was the first time I ever worked on a washing machine, and by checking out the parts first and comparing everything,even someone that might not have much mechanical skills can change this out. My washer works fine and not a drop of water leaks anymore.One thing I did learn, if you change this part out and put it back together and try it out and it makes a funny sound and you smell something like its burning, you might did what I did. I thought I had it to tight, but I put the large nut on before I put the tub back on!!! The agitator was holding the tub down, but it could not spin in spin cycle.... Good luck with you repairs, you can do it.

Parts Used:

-

Brian from Bush, LA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

7 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Worn belts

All I had to do is tilt the machine to expose the bottom and replace the belts. It was fast, easy and the machine works fine now.

Parts Used:

-

Ronald from Birmingham, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

8 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer Leaked Water From Bottom Seal

Removed washer tubs inner and outer nut (part # 10 ) on inner was hard to remove and is a reverse thread used hammer to loosen once off removed 1st tub - then removed set screw #17 and then unscrewed mounting s item #29 this again required some hammer tapping to loosen - once off used flat head screwdriver to pry & remove the rubber piece on bottom of outer or 2nd tub -but keep going as the leak will probably be from part #20 tub bearing ( this will save you the time to test and find out it still leaks and have to take apart again after only replacing #29 removed 3 bolts holding tub - disconnected hoses and removed 2nd tub - used rubber hammer to knock out and install #20 tub bearing - reasembled and wow no leaks to cost about $120 - time worked on 3 hrs - only because took apart 2 times - down time on washer 10 days as we didn't order all parts to start with no beer needed but did enjoy a nice red wine - good luck

Parts Used:

-

JACLYN from RICE LAKE, WI

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer making high pitched squeal at stopping of spin cycles

My washer is apparently 37 years old. I bought it used in the 90’s and have had to do little or nothing to it repair wise. It started to make a loud squeal/squeak when the spin cycle stopped. I watched a couple videos showing the brake assembly, bearings and belt replacement and was able to find parts. However, one bearing appears to no longer be made (just repacked with heavy duty grease) and the special tool is nonexistent. I read others using a chain clamp vise to remove the brake assembly and bought a 20 inch chain clamp vise and a 3 set variety of vise grip pliers for about $20. They make an 18 inch chain vise but glad I got the 20 inch. I used two vise grip pliers to clamp chain around notch two notches that the specialty tool would normally grab. It was a cumbersome getting in there to whack the pliers with a small sledge hammer so I got a approx 18 inch 2x4 and cut a notch at the end to keep chain vise from digging into bottom of washer and whacked the end of the 2x4. Seemed to work ok and did the same to tighten back after replacing break assembly. Got it out back together and no more squeal.

Parts Used:

-

Chad from BOERNE, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

After 29 yrs, tub top clamp broke from vibration

Removed front, loosened top & tilted up. Placed tub top assuring it would not rub inner basket. Placed clamp on Ridge & gasket & tightened. Reassembled & started washing.

Parts Used:

-

David from ROCK HILL, SC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken belt

It was as simple as leaning the machine back far enough so I could get to the belts - which were on the bottom. The diagrams that came with the ordered parts were right on. This is the first time I have attempted this myself - my repairman has retired - I'm sure I will do it again.

Parts Used:

-

Edith from Cornwall, NY

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

6 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer made screeching sound during spin cycle. Also, the clothes were still very wet at end of spin cycle.

I used two vise grip wrenches in place of specialized tool that is no longer available. I put the vice grip wrenches on the brake assembly and hit them alternately with a hammer. I also used penetrating oil.

Note, the parts package stated made in USA but the bearings had China stamped on them.

Note, the parts package stated made in USA but the bearings had China stamped on them.

Parts Used:

-

Edward from EUCLID, OH

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The old pump was beginning to drag due to the age of the washer.

Removed the front panel. Then blocked up the front of the machine. Removed the pump belt. Removed the 3 5/16" screws from the bottom of the old one and tilted it slightly to remove. Put the new one in and reinstalled the 3 screws. Put the belt back on and slid new pump all the way to the right and tightened 1 screw. Loosened the screw until there was about 1/4" of gap when squeezed the belt together. Tightened the one screw, then the other 2. Put the front panel back on and lowered the machine. New pump works great.

Parts Used:

-

Howard from ALBRIGHT, WV

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

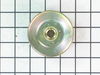

Noise from dryer in spin cycle,

Found noise to be belt slapping the base sheet metal, from being too loose. Belt was loose because the drive pulley was worn and one side of pulley was loose! Used allen wrench to loosen the pulley set screw, and pryed off the old pulley. Replace d with new pulley and new belts. Works and sounds like new!

Parts Used:

-

curtis from ROCKDALE, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water was leaking from under the front of the washer when it was used.

After turning the water off and unplugging the machine, I took the front panel off the washing machine. I then slipped the belt off the pump sprocket. The pump was right in the front and easy to remove. All I needed was a screwdriver, for the hose clamps, and a 5/16" socket to remove the old pump. I then installed the new pump, with the existing screws, re-attached the 2 hoses, slipped the belt back on, and popped the front panel back into place. The new pump works great and the leak is gone. The whole job onlt took about 30 minutes.

Parts Used:

-

Greg from Manhattan, KS

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Belts

Lets just say thank god for part select!!!! # 1 By far. This was a one two three job.

Parts Used:

-

tommy from cortlandt manor, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

8 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Repairs Were Easy.

Removed top. Removed agitator and tubs . Replaced seals and reassembled.

Parts Used:

-

James from Ventura, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

11 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The washing machine ran noisily

Remove the power cord and water hoses. Lay the machine on the floor. Remove two belts (washing and pumping). Unlock the screw of pulley using a hex key. Remove the broken pulley from the motor. Place in the new pulley. Lock the screw of the pulley. Install two belts. Turn the machine vertically. Plug in water hoses and power cord. Level the machine.

Parts Used:

-

Xuanbao from Norwalk, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

5 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken belt

Layed the machine on it'sback and put the 2 belts on the pulleys,Very easy ,when you know to put the machine on it's backside!

Parts Used:

-

Ray from Cool, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

pump and drive belt was thorn

Installed drive and pump belt.. very very simple. only tool required was a screw drive to remove front panel of the washing machine.

Parts Used:

-

Henry from KITTERY, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!