911413 - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Oven tempature was approximately 150 degrees to low

This repair is EASY if you know how to use an ohm meter. If not, seek help for this step.

SYMPTOM:

The oven (JKP27WOP3WG or JKP27WP3WG and many ovens like it ) was not getting hot enough. Verifying the cooking temperature with an typical oven thermometer, I was able to determine that the oven was cooking temperature was about 150 degrees to low.

FAILURE POINTS:

There are two logical failure points (1) The oven sensor ( WB21X5301 about $75), or the (2) the controller board (PS238233 about $252). In my case it was the controller board. When replaced the oven worked beautifully.

REPAIR:

As with any repair, you MUST DISCONNECT POWER TO THE UNIT BEFORE SERVICING!!!

Pull oven from the wall:

- Disconnect power by flipping the circuit breaker to the OFF position.

- Remove the top flange / cowling from the top of the oven (it just pulls off)

- Remove two screws under the top flange / cowling

- The whole unit easily slides out, but it is highly recommended that you use two people to place the oven on the floor.

As a diagnostic between these two parts, if the oven sensors measure approximately 1.1K ohms of resistance at room temperature, then it is probably not the sensor. The oven sensor wires are connected to two white wires that run up to the controller board. You need to disconnect the oven sensor to make the measurement. You may either completely remove the oven sensor by cutting the wire (be sure to allow yourself enough slack so that they may be safely reconnected) where it connects to the white wires, OR, (preferred method) if leaving the oven sensor partially installed,

- Remove the top sheet metal cover (10 screws)

- Remove the service connect cover (2 screws - this is where the main Power cord comes into the unit)

- Disconnect the white wires from the controller board (this connector which also includes other circuits is on the left side when looking at the controller board).

- Remove two screws from oven sensor but just let in dangle down so that you can put the sensor in the ice water / boiling water.

Measure the resistance under the following conditions. Your ohm meter should read APPROXIMATELY...

- 1.02K ohms in ice water

- 1.09K ohms at room temperature

- 1.36K ohms in boiling water.

If you get approximately these readings, then it is NOT the oven sensor. If that checks out then re-install the sensor AND the connector.

If it is NOT the sensor, replace the controller board.

- Take a moment to write down the color of the wire to the LETTERING (N, L, G, C / COM,,,) on the controller board. The connectors are in different locations on the new controller board so the wire color to the letter designation is significant.

- Carefully remove the wires one at a time

- VERY carefully remove the keypad ribbon cable from the right side of the controller board.

-- The ribbon cable will disconnect by releasing some little pressure clips on the side of the connector.

- Remove the controller board (4 screws)

- Install new controller board (4 screws)

- VERY carefully connect the keypad ribbon cable on the right side.

-- Make sure that the connector is in the OPEN position first, then,

-- Slide in the cable ensuring that all parts of the ribbon made it into the connector, then

-- Press down on the connector locking tabs.

- Reconnect each wire to the correctly lettering on the board.

-- Again, the connectors MAY BE in a different order on the replacement controller board. Match color to letter.

- Reconnect the (5 wire?) connector that includes the white oven sensor wires.

- Make sure everything looks normal, (i.e. no wires are pinched, remove tools from top of oven area, etc.)

- Re-install top cover.

- Re-install service connect cover.

You can test the unit while it is out of the cabinet,

- Make SURE that all sheet metal covers are in place.

- Flip power breaker to "On".

- Test that oven gets to the desired temp.

SYMPTOM:

The oven (JKP27WOP3WG or JKP27WP3WG and many ovens like it ) was not getting hot enough. Verifying the cooking temperature with an typical oven thermometer, I was able to determine that the oven was cooking temperature was about 150 degrees to low.

FAILURE POINTS:

There are two logical failure points (1) The oven sensor ( WB21X5301 about $75), or the (2) the controller board (PS238233 about $252). In my case it was the controller board. When replaced the oven worked beautifully.

REPAIR:

As with any repair, you MUST DISCONNECT POWER TO THE UNIT BEFORE SERVICING!!!

Pull oven from the wall:

- Disconnect power by flipping the circuit breaker to the OFF position.

- Remove the top flange / cowling from the top of the oven (it just pulls off)

- Remove two screws under the top flange / cowling

- The whole unit easily slides out, but it is highly recommended that you use two people to place the oven on the floor.

As a diagnostic between these two parts, if the oven sensors measure approximately 1.1K ohms of resistance at room temperature, then it is probably not the sensor. The oven sensor wires are connected to two white wires that run up to the controller board. You need to disconnect the oven sensor to make the measurement. You may either completely remove the oven sensor by cutting the wire (be sure to allow yourself enough slack so that they may be safely reconnected) where it connects to the white wires, OR, (preferred method) if leaving the oven sensor partially installed,

- Remove the top sheet metal cover (10 screws)

- Remove the service connect cover (2 screws - this is where the main Power cord comes into the unit)

- Disconnect the white wires from the controller board (this connector which also includes other circuits is on the left side when looking at the controller board).

- Remove two screws from oven sensor but just let in dangle down so that you can put the sensor in the ice water / boiling water.

Measure the resistance under the following conditions. Your ohm meter should read APPROXIMATELY...

- 1.02K ohms in ice water

- 1.09K ohms at room temperature

- 1.36K ohms in boiling water.

If you get approximately these readings, then it is NOT the oven sensor. If that checks out then re-install the sensor AND the connector.

If it is NOT the sensor, replace the controller board.

- Take a moment to write down the color of the wire to the LETTERING (N, L, G, C / COM,,,) on the controller board. The connectors are in different locations on the new controller board so the wire color to the letter designation is significant.

- Carefully remove the wires one at a time

- VERY carefully remove the keypad ribbon cable from the right side of the controller board.

-- The ribbon cable will disconnect by releasing some little pressure clips on the side of the connector.

- Remove the controller board (4 screws)

- Install new controller board (4 screws)

- VERY carefully connect the keypad ribbon cable on the right side.

-- Make sure that the connector is in the OPEN position first, then,

-- Slide in the cable ensuring that all parts of the ribbon made it into the connector, then

-- Press down on the connector locking tabs.

- Reconnect each wire to the correctly lettering on the board.

-- Again, the connectors MAY BE in a different order on the replacement controller board. Match color to letter.

- Reconnect the (5 wire?) connector that includes the white oven sensor wires.

- Make sure everything looks normal, (i.e. no wires are pinched, remove tools from top of oven area, etc.)

- Re-install top cover.

- Re-install service connect cover.

You can test the unit while it is out of the cabinet,

- Make SURE that all sheet metal covers are in place.

- Flip power breaker to "On".

- Test that oven gets to the desired temp.

Parts Used:

-

James from Austin, TX

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

220 of 258 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

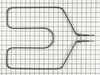

bake element shorted out, sparking like a sparkler

first, made sure circuit breaker was off

second, used nut driver to remove 2 screws on old element, pulled it from the back of the oven

third, removed 2 wires from old element (spade connectors)

fourth, connected new element and pushed back into oven.

fifth, reinstalled 2 screws securing new element

this was all done by my 15 yr old son under my supervision.

second, used nut driver to remove 2 screws on old element, pulled it from the back of the oven

third, removed 2 wires from old element (spade connectors)

fourth, connected new element and pushed back into oven.

fifth, reinstalled 2 screws securing new element

this was all done by my 15 yr old son under my supervision.

Parts Used:

-

Carl from Wynnewood, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

89 of 97 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The broiler element caught fire and burned out while I was broiling a steak.

First I removed the two screws that hold the element in place. I then pulled the element out about 3 inches, but I had not turned off the power.

So, I shorted out one of the wires. Then I turned off the power but was afraid to go any farther.

An appliance repairman was at my house that day fixing my dryer seal. He was able to pull the wires through the insulation successfully and install the broiler element. He did not charge me any extra for this little extra job. But I learned my lesson. Cut the power before you begin! He told me that I could have wound up with a much bigger repair if the short had been in the wire that is connected to the control panel of the oven. I was very lucky!

So, I shorted out one of the wires. Then I turned off the power but was afraid to go any farther.

An appliance repairman was at my house that day fixing my dryer seal. He was able to pull the wires through the insulation successfully and install the broiler element. He did not charge me any extra for this little extra job. But I learned my lesson. Cut the power before you begin! He told me that I could have wound up with a much bigger repair if the short had been in the wire that is connected to the control panel of the oven. I was very lucky!

Parts Used:

-

Dianne from Rockville, MD

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

67 of 75 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

oven door seal was old and falling apart

at first thought the seal would just slide out and the same for the replacement. when I realized that this was not the case and began to wonder what....? I saw the screws at top and bottom, took them off and voila the inner shell moved forward enough to take out the old, slide in the new, push in, replace the screws and back to a happy wife with an oven that can bake correctly again

Parts Used:

-

eric from washington, DC

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

56 of 67 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top broiler element went out

FIRST MAKE SURE THE OVEN IS OFF!!!! I chose to shut it off at the breaker panel. Remove the two screws that attaches the broiler element to the oven. Gently pull it out. Unplug the two cable wires that are attached. Replace it and install the same way.

Parts Used:

-

Kim from Garland, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

39 of 42 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven used broiler element not bake to maintain temp

Pulled Circuit Breaker to turn off power to oven

Removed oven door just to get it out of way

Removed top panel by removing two screws on

underneath panel left and right

Panel must be lifted to releace from two guide pins

At top, I used towel protect panel and layed panel

down flat.

I drew picture of old ERC and labeled where each

Wire went and what color it was.

I removed old ERC by removing four screws and

placed it next to new ERC.

I made drawing of new ERC-3 and decided where

each wire would go.

The replacement instruction apeared difficult to me the first time I read them, but after finding the

Small stamped letters on the broil and bake controls on the ERC it became fairly easy.

There are more connections on the new ERC

Than I needed for my Installation. I installed the

New ERC and everything worked fine.

Removed oven door just to get it out of way

Removed top panel by removing two screws on

underneath panel left and right

Panel must be lifted to releace from two guide pins

At top, I used towel protect panel and layed panel

down flat.

I drew picture of old ERC and labeled where each

Wire went and what color it was.

I removed old ERC by removing four screws and

placed it next to new ERC.

I made drawing of new ERC-3 and decided where

each wire would go.

The replacement instruction apeared difficult to me the first time I read them, but after finding the

Small stamped letters on the broil and bake controls on the ERC it became fairly easy.

There are more connections on the new ERC

Than I needed for my Installation. I installed the

New ERC and everything worked fine.

Parts Used:

-

Travis from Thomasville, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

34 of 46 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Our double oven stopped working and an F7 error message was displayed with an audible alarm sound. We had to power off the double oven in order to eliminate the alarm sound. The oven manual said to contact GE service.

Based on the model number of the unit, I was able to locate the part that I need from the Partselect.com web site. It was very easy to order and I recieved the part very fast. To my surprise, I only had to remove a total of 6 screws. First, I removed the two screws that hold the oven panel in place. After popping the panel away from the oven frame, I angeled it so that I can remove the four screws holding down the old oven control. Once removed, I replaced with the new part, replaced all of the color coded wires, followed by screwing the panel back into place. Very easy to do and saved tons of money.

Parts Used:

-

Joe from Annandale, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

29 of 33 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven would not heat to the correct temperature

First I removed the two screws that hold the element in place. I then pulled the element out about 3 inches and disconnected the two wires

Parts Used:

-

Michael from Lawrenceville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

37 of 60 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

F2 error message on my GE oven indicated need for new heat sensor

After unscrewing the old heat sensor from inside the oven, I pulled the range away from the wall, got behind it and removed the small panel over the heat sensor. Naturally, the plastic clips connecting the heat sensor to the range wiring wouldn't come apart, so I eventually had to simply pry them apart with two pliers. Then, naturally, the new plastic connector clip on the replacement part didn't match the clip from the range, so I had to cut off both receptacles and strip the wires, then used the provided wire nuts to make the connections. After that, it was easy, just secured the heat sensor inside the oven and replaced the panel. I didn't push the range back against the wall until I tested the repair. It worked fine!

Parts Used:

-

Joseph from Brick, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

25 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

bake element burned itself out ( as a welding rod does with all the fireworks)

removed 4 screws of the back fan cover, then removed the two screws holding the element and disconnected the slip-on electrical wire connections. replaced enement and cover in reverse. this was all done after i cut power at circut breaker duhh

Parts Used:

-

joseph from ferrisburg, VT

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Socket set

21 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Bake Element Burned Through A Weak Section Of The Tube.

I removed the two mounting screws then pulled the element forward and disconnected the two element screws. I reversed the process to install the new one/ this oven is over 30yrs old.

Parts Used:

-

PAUL from CAMDEN, AR

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

17 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replacement of heating element

If I'd had the Nut driver, it would have taken 15 -20 minutes or less. Went to Ace Hardware, bought the nut driver for $4.99.

Turn off the power at the box! Turn off the oven as well. Four screws total. Two to hold it in place and two that connect the element to the source.

First I removed the two screws that hold the element in place. I pulled the element out about 2 inches. Two more screws connect the element wires. I disconnected the element, threw it away, then connected the new element. I put the element in place, then replaced the screws that connect the power. Finally, I replaced the screws that hold the element in place.

Kimberly, El Cerrito, California

Turn off the power at the box! Turn off the oven as well. Four screws total. Two to hold it in place and two that connect the element to the source.

First I removed the two screws that hold the element in place. I pulled the element out about 2 inches. Two more screws connect the element wires. I disconnected the element, threw it away, then connected the new element. I put the element in place, then replaced the screws that connect the power. Finally, I replaced the screws that hold the element in place.

Kimberly, El Cerrito, California

Parts Used:

-

Kimberly from El Cerrito, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

16 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

oven shut down code F3

As has been said shut down unit,Breaker fuse.If you do not have install info.Get a copy on line. If you have another set of hands it would not hurt.! this has been stated before. Remove door, Remove 4 screws , to slide unit out,I used a saw horse with some cribing secured to the horse to get height, Pull the oven out so that the two front supports are on the saw horse,and the back two are up to the edge runner.I used about a 1 ft stool for working height. Remove the top elec. cover sheet metal 2 screws. You will see were the wireing runs down the back. Get a small mirror,and flash light. Look down the wire opening in the back, you see the sensor connection ,I made a hook out of a coat hanger to grab it with. Pull it up before you disconnect it ,tie a piece of string to the sensor side of the connector , use 2 Ft. then disconnect remove two screws from inside the oven. And remove,sensor tie string on to new sensor connector pull through and connect.on top.Then replace everything cck every thing Twice!Doing this i didn"t have to pull the unit all the way out! LATER GOOD LUCK!

Parts Used:

-

Richard from Jupiter, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

17 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

oven would not cook over 325 degrees and sometimes would burn your food.

I removed the unit from the wall,removed the back panel to access the wires to the sensor,cut the plug off of the new sensor and strip the wires back,used the wire nuts to attach the new sensor,put all back together and slid back into the wall and works excellent.

Parts Used:

-

phil from forney, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

15 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Received an "F7" fault code and beep

After several years of dealing with the random faulting "F7" code and turning the power off of the oven until it was needed, I decided to replace the control module. I looked up the model and ordered the replacement part.

When the module arrived, it was was a little different from the OEM module, terminal wise, but not significant, so it was easy to unplug the bad one and plug in the new one. A total of six screws, unplug a few wires, remove the old module, plug the wires back in and I'm back in business.

I'd suggest that novice do-it-yourselfers take a picture of the back of the old module with wires in place, before disconnecting for reference. If no camera is available, simply make a basic drawing of terminal locations/names or use one of the pictures from the new instructions to lable your old terminals, before disconnecting. NOTE: Three terminals were relocated to the top of two relays, with one of the relays requiring two wires to be connected.

When the module arrived, it was was a little different from the OEM module, terminal wise, but not significant, so it was easy to unplug the bad one and plug in the new one. A total of six screws, unplug a few wires, remove the old module, plug the wires back in and I'm back in business.

I'd suggest that novice do-it-yourselfers take a picture of the back of the old module with wires in place, before disconnecting for reference. If no camera is available, simply make a basic drawing of terminal locations/names or use one of the pictures from the new instructions to lable your old terminals, before disconnecting. NOTE: Three terminals were relocated to the top of two relays, with one of the relays requiring two wires to be connected.

Parts Used:

-

GARY from SUGAR LAND, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

12 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!