Parts That Fix Whirlpool Dryer GEQ9800PW1 Noisy

Noisy is a commonly reported symptom for the GEQ9800PW1 Whirlpool Dryer, and we have put together a full guide on how to fix this. This advice is based on feedback from people who own this exact appliance. We have listed the most common parts for your GEQ9800PW1 Whirlpool Dryer that will fix Noisy. We have included repair instructions, and helpful step-by-step video tutorials. If you are experiencing this issue, not to worry, DIYers just like you have fixed this, and shared their experience to help you!

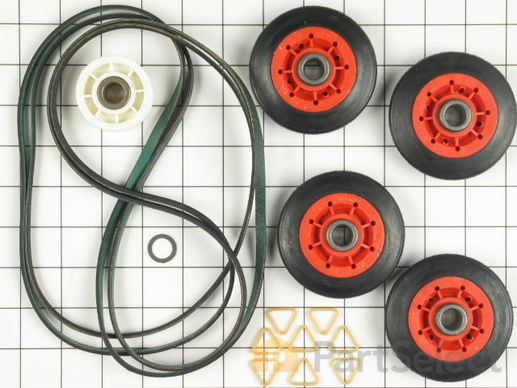

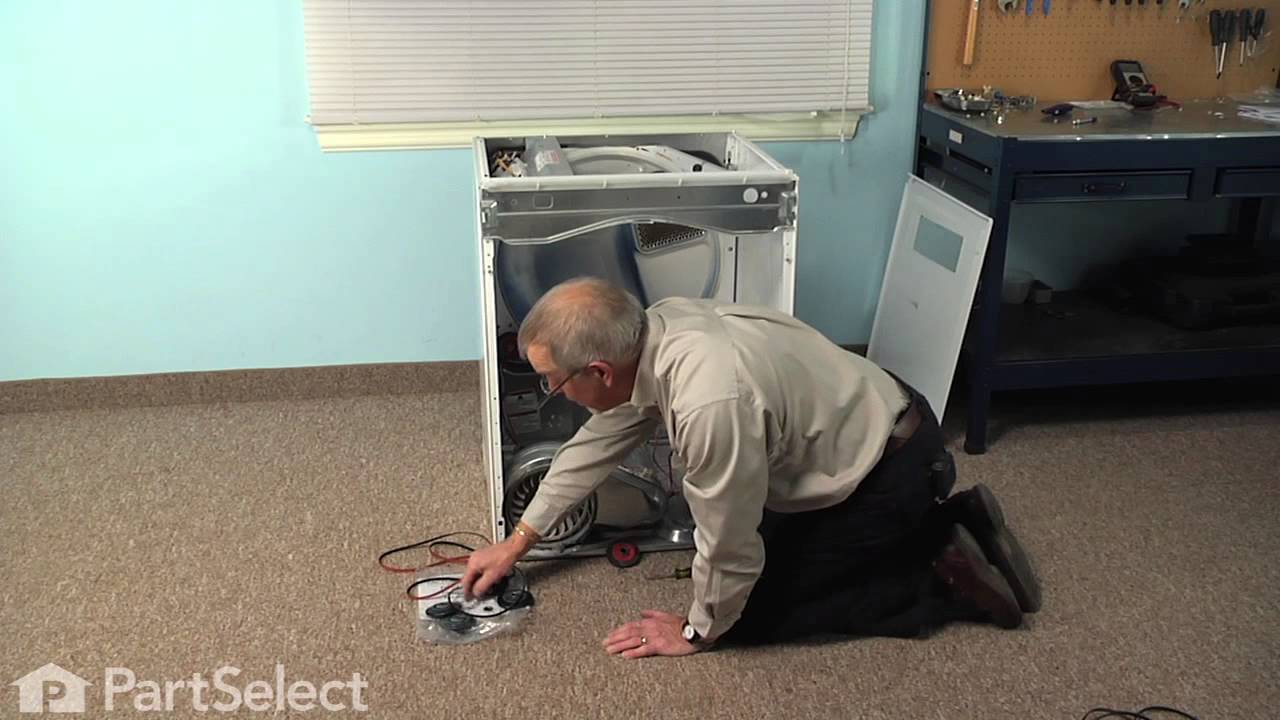

This dryer repair kit consists of five commonly replaced dryer parts: one multi-rib belt (part #661570V and measures 93 1/2 inches long), four drum support rollers, one idler assembly, nine tri-rings, and one washer. This universal maintenance kit is an all-encompassing kit for fixing a noisy dryer, among other symptoms, but noisy being the most common. It is compatible with 27-inch wide dryers built from 1965 onwards. Be sure to disconnect the dryer or shut off the house circuit breaker for the appliance before you begin your repair. To access these parts, you will need to remove the dryer drum. For this installation you will need a 1/4-inch nut driver, a long flat-blade screwdriver, a short flat-blade screw diver, and a Phillips screwdriver.

Replacing your Whirlpool Dryer Dryer Repair Kit

Customer Repair Stories

Squeaky Dryer Noise

-

Eddie from PELZER, SC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

very loud squeeling sound

-

jason from HOLDEN, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

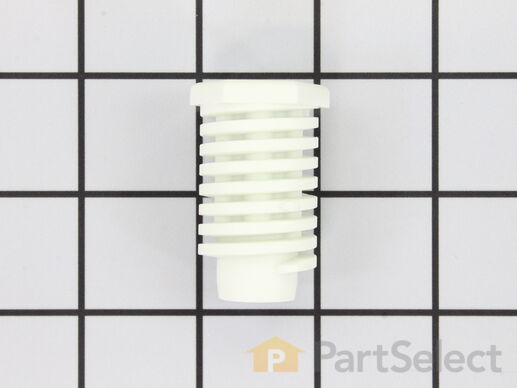

This Idler Pulley includes the tri-ring and gasket and everything included here is manufacturer-certified. This part maintains correct tension on the drive belt in order to spin the drum properly. If damaged or broken the dryer will not dry properly, will not tumble properly, or may not even start. Installation is rated as "Medium" difficulty. This part is located on the dryer drum, around the tension pulley. Refer to your user manual and model number for repair instructions and to ensure this part is right for you. For this repair project, the tools needed are a Phillips screwdriver, 1/4 inch nut driver, putty knife, small flat blade screw driver, and needle nose pliers.

Replacing your Whirlpool Dryer Idler Pulley

Customer Repair Stories

TOb stopped turning after a week or so of high pitched "squeals" coming from inside the dryer.

-

Robert from Princeton, WV

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

Very Loud Squeaking Noise

-

GREGORY from Wilsonville, OR

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

This drum support roller is sold individually. Most dryers require two. The tri-rings are included. This is a drum support roller for a dryer. It is a genuine replacement part. The part includes the drum roller only and does not include the tri-rings. This part is sold separately. Most dryers require two drum rollers. It is recommended to check and replace both drum support rollers at the same time to ensure proper drum rotation and because they often wear at the same rate. The drum support roller holds the drum in the proper position while it spins on the support wheels. If rollers are worn out, they will cause the dryer to be noisy.

Replacing your Whirlpool Dryer Dryer Drum Support Roller

Customer Repair Stories

Dryer drum turned hard because rollers were worn

-

Paul from STONE CREEK, OH

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

noisy drum

-

Jeff from Mesa, AZ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable), Wrench set

The idler pulley wheel is now sold with this arm. This idler pulley is for dryers. Idler pulley maintains correct tension on the drive belt to spin the drum.

Replacing your Whirlpool Dryer Idler Pulley with Bracket

Customer Repair Stories

Idler pulley wore out

-

Peter from HUEYTOWN, AL

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

Dryer made a terrible screeching noise when tumbling.

-

Richard from SAUGERTIES, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

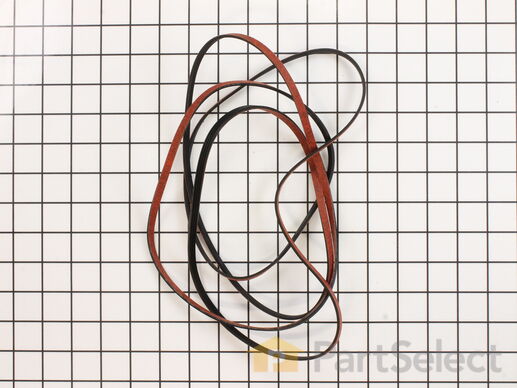

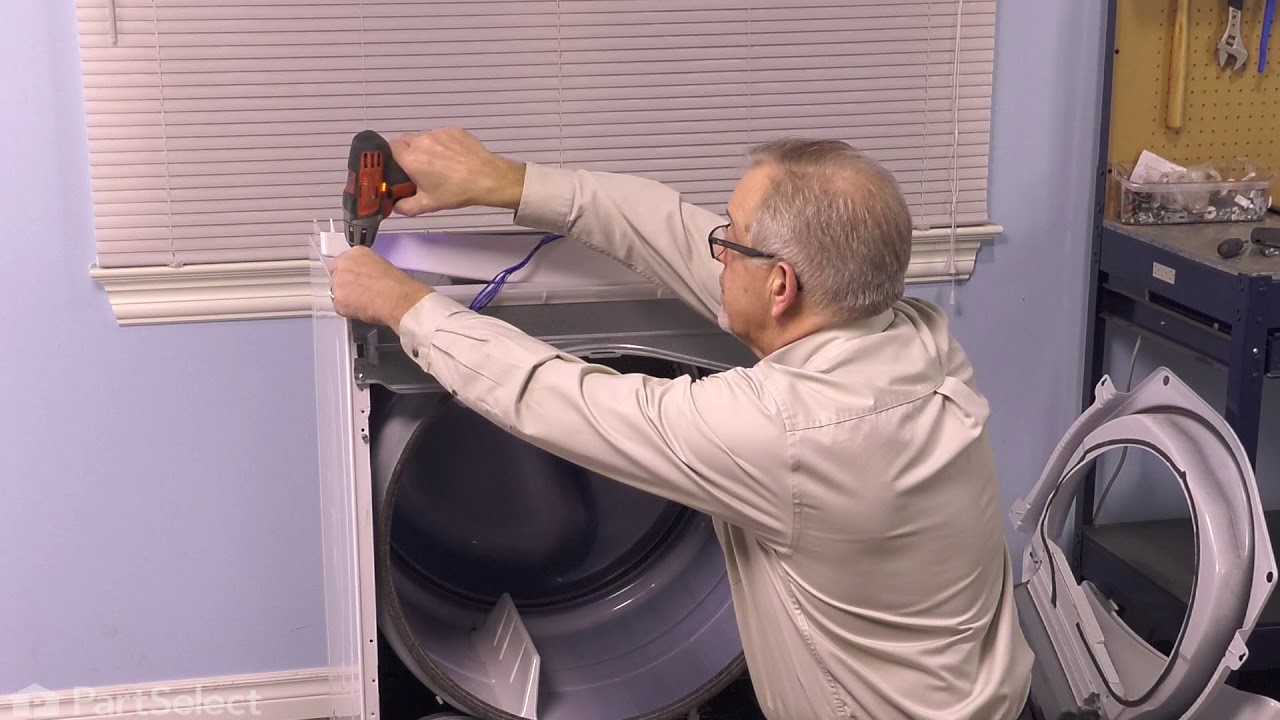

The Drive Belt is a 93 1/2" belt which wraps around the dryer drum to allow tension and movement. If broken the dryer will not turn properly, or there may be loud noises. The part is rated as "medium" difficulty to install. Refer to your model number and user manual to ensure this part is correct for you. To complete this repair you will need a Phillips screwdriver, 1/4 inch nut driver, a putty knife, and a pair of needle nose pliers. Ensure you disconnect your power to the dryer before beginning this repair, which should take between 30 and 60 minutes maximum to complete.

Replacing your Whirlpool Dryer Drive Belt

Customer Repair Stories

Belt was raffling and there was aloud knocking sound

-

Genette from CLEVELAND, MS

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

Broken Belt

-

Ken from LOMBARD, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

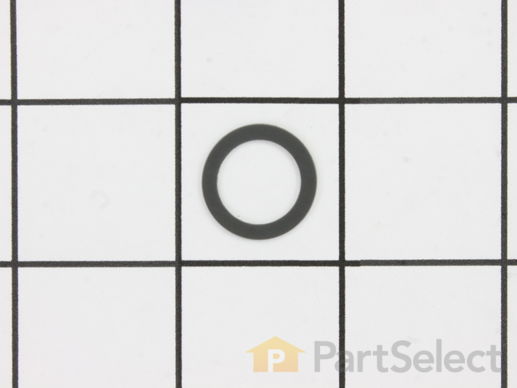

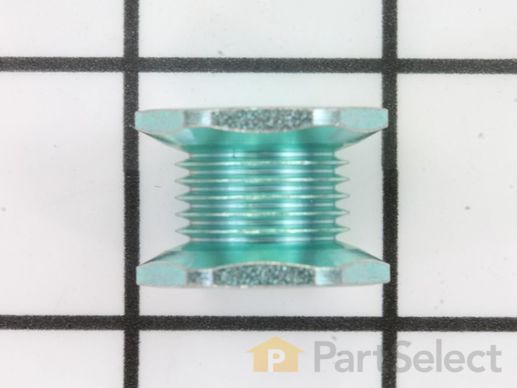

If you notice that your dryer is noisy or will not tumble, you may need to replace the tri ring. This part is triangular, and is less than an inch in size. Tri rings can be found both on the idler pulley shaft, or on the rear drum roller shaft. In either case, you will need to remove the front panel of the dryer and the drum to access the part for repair. Once you have accessed the damaged tri ring, you will simply need to slip it off and replace it with the new one. This part is sold individually. Be sure to disconnect the power source from the dryer before you begin this repair.

Replacing your Kenmore Dryer Roller Support Tri-Ring

Customer Repair Stories

My daughter threw a heavy wet comforter into the dryer and the tri-ring sheared off.

-

Joe from St. Louis, MO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

This genuine OEM washer has a 3/4 inch outside diameter. This thrust washer can be used on most makes and models of dryers. A complete list of compatible dryers is available below. The washer is found on dryers around the drum support rollers and idler pulleys, and helps prevent the rollers and pulleys from bumping up against the brackets they are installed on. Your thrust washer could be defective if you notice your dryer wont tumble, rotate, or turn; or there is a load squealing or whining noise when the dryer tumbles. The repair is a relatively easy job. You will require a putty knife, 5/16 inch nut driver, and E-Ring pliers. Remember to disconnect the power to your dryer before you begin the repair.

Replacing your Amana Dryer Thrust Washer

Customer Repair Stories

Clanging of dryer when rolling

-

John from Bel Air, MD

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

belt was cracking and dryer was somewhat noisy

-

Melody from Silverton, CO

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

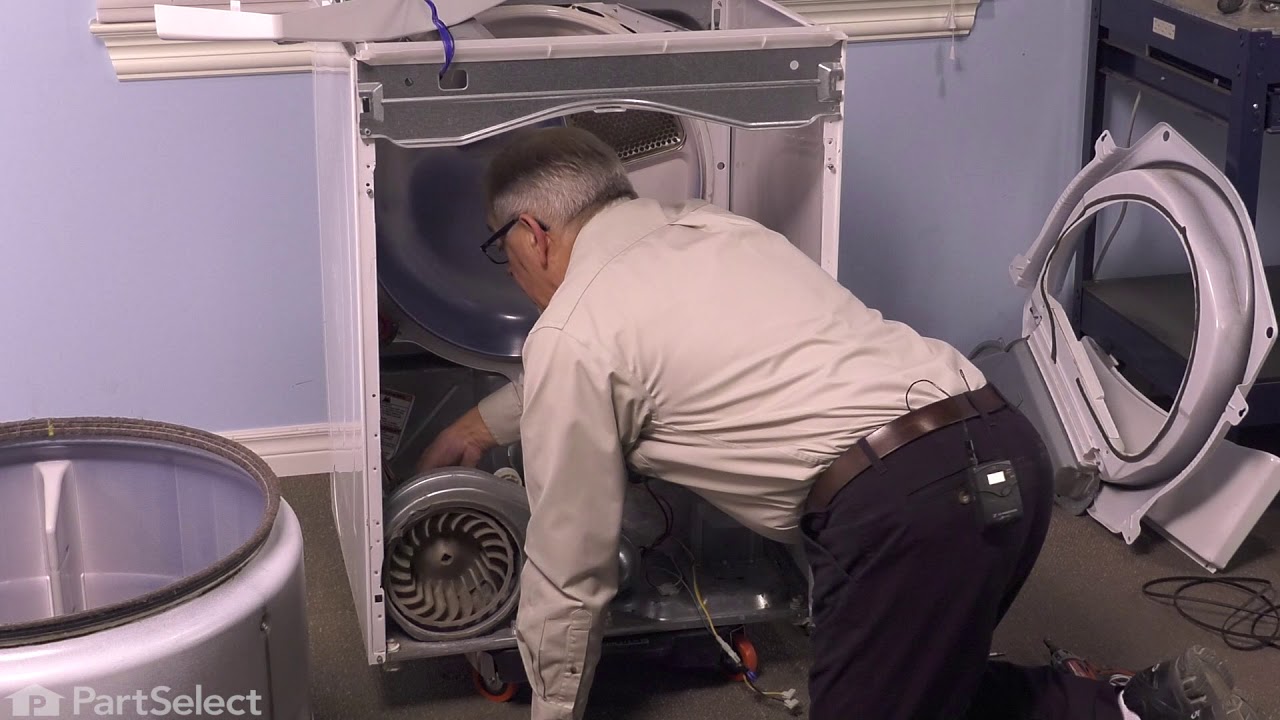

The blower wheel pulls air over the heat source, through the clothes drum, and past the thermostats, then pushes it out the exhaust duct. The blower wheel, which is usually plastic, may wear out over time. But if it's noisy, it may simply be clogged with lint. Clean the blower and test to see if the dryer is still noisy. If it is, you probably need to replace it.

Replacing your Whirlpool Dryer Blower Wheel

Customer Repair Stories

craked blower motor

-

joe from cheswick, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

This drum seal with a silicone rubber adhesive is used in dryers. This part seals the drum to make sure air does not escape from the dryer. If your dryer is making loud noises, is not producing enough heat, or no heat at all, or there are marks left on your clothes, replacing the seal on your dryer can solve the problem. The tools needed for this installation project are: 1/4 inch nut driver, Phillips screwdriver, small flat blade screwdriver, and putty knife. Remember to unplug your dryer from the power source before beginning this installation project. Refer to the manual provided by the manufacturer for installation instructions.

Customer Repair Stories

Rear dryer drum seal came out

-

William from Pontiac, MO

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

Rear tub seal failure

-

Jerry from Everett, WA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

Shaft for dryer drum support roller. Rear shaft with left hand threads. Part is updated so nuts may need to be replaced as well on older dryers.

Replacing your Whirlpool Dryer Drum Support Shaft - Rear Shaft with Right Hand Threads

Customer Repair Stories

Rollers making a noise.

-

Carl from MARION, KY

-

Difficulty Level:Really Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Socket set

This front shaft with right hand threads is used in dryers. The shaft and the drum support rollers ride on to support the drum. If your shaft has flat spots and the rollers do not spin, replacing the shaft can solve the problem. The tools needed for this repair are: 5/16 inch socket or nut driver, 1/4 inch socket or nut driver, small flathead screw driver, channel-lock pliers, 9/16 inch socket. Remember to unplug your appliance from the power source before beginning this installation project. Refer to the diagram provided by the manufacturer for further installation instructions.

Replacing your Whirlpool Dryer Drum Support Roller Shaft - Right Hand Threads

Replacing your Whirlpool Dryer Spring

This part is located on the drum roller support shaft in your dryer appliance. The exterior of the washer is 1 inch in diameter with a hole in the middle and is made of metal. They are installed alongside the drum support rollers and idler pulleys. If you notice that your dryer is making an unusual sound it could be due to the washer becoming loose on the drum support. They help prevent the rollers and pulleys from bumping up against the brackets they are installed on. If you are replacing the rollers, we suggest you replace the washers at the same time.

If your washer shakes or vibrates loudly when it reaches its max speed, check that the leveling legs are even. To ensure that the washer is firmly on the ground using all four legs, adjust the legs so that the machine is level, and tighten the locking nuts on the legs that are threaded. Keep the washer as close to the floor as possible. Your model might have rear legs that level themselves, or it might have threaded legs all around. Make sure the rubber feet have not worn out. Replace any missing or damaged legs and feet. This replacement part is sold individually.

Replacing your Kenmore Dryer Leveling Foot

Replacing your Kenmore Dryer Leveling Foot

Customer Repair Stories

Washer overflowed

-

Beth from Valley Springs, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

No leveling feet on dryer.

Instructions:

1. Tip dryer over onto a non-scratch surface. I used a tarp on the floor.

Insert leveling foot into the foot opening on the bottom of the dryer &

screw in with fingers until it is difficult to turn.

2. Use t ... Read more he adjustable wrench on the hexed foot (not the threads) to adjust to the desired level.

3. Tip dryer upright taking care not to exert pressure on the feet closest to floor. I used a folded-up tarp under the bottom edge of the dryer while lifting it to the upright position.

4. Use a level, back to front & side to side, to determine if feet need further adjustment.

5. Adjustments can be made with the dryer in the upright position, using the adjustable wrench on the hexed foot.

-

Bobbie from BEND, OR

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Wrench (Adjustable)

Sold individually.

The blower shaft is 1-5/8 inches long, while the drive shaft is 1-1/4 inches long.

Replacing your Kenmore Dryer Drive Motor with Threaded Shaft - 120V 60Hz

Customer Repair Stories

Dryer would start and then stop after a few minutes, eventually it completely stopped.

I input the number into the search box and there was the exact motor I needed.

The correct part showed up in a timely manner and the pricing was very fair.

I disassembled the dryer, ... Read more removed the old motor and reinstalled the new motor within about 30 minutes.

Key point was to read the instructions first and then reconnect the wiring to the new motor. The new motor has the switch install in a different spot on the motor so be careful to follow the instructions but, the instructions were very clear and connections were very simple.

I also did some preventive maintenance while I was in the unit by cleaning out any remaining lint from the heater unit and surrounding areas, that took about 30 minutes. Reassembling was a snap and I turned on the gas, plugged it in and........SUCCESS! Total time of repair and cleaning was about an hour.

I had a load of laundry ready to go and put the new motor right to work. It has been non-stop drying and thanks to Part Select for getting everything right the first time. It has been a positive experience and I will tell others about the website if they have similar problems. Thanks again for a success story and dry clothing.

-

Keith L. from San Diego, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Wrench (Adjustable)

Our dryer started squealing and would then stop running.

I input the number into the search box and there was the exact motor I needed.

The price was fair and the delivery quick so I figured I would give yuo guys a shot and see how it goes.

The par ... Read more t showed up on time and as expected. It was well packed and most importantly - it was the CORRECT part.

I disassembled the dryer which involved removing the lint trap, pulling out the blower fan and removing the motor cover. The motor was held in with 2 metal screws and wiring harness.

I took the belt off of the tensioner and pulled out the old motor. The motor was mounted with 2 clips which snapped off with ease. Reassembly was a breeze since the motor fit perfectly- the entire transplant operation took all of about 35 minutes.

I crossed my fingers, turned on the gas, plugged it in and........SUCCESS!

Since the dryer was down for over a week the backlog of laundry was piled pretty high. This replacement motor would immediately be put to the test.

It has been 5 days of non-stop drying and no squeeks, no squeels and nothing but dry clothes!

Thanks to Part Select for getting everything right the first time. It made a potentially very bad experience turn out as good as I could have ever hoped.

-

Kelly from Aptos, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Wrench (Adjustable)

This part is the replacement motor pulley for your dryer. The motor pulley allows the dryer belt to run straight while the dryer is operating. If your motor pulley is damaged, your dryer may not tumble, and may not start altogether. A damaged motor pulley can also damage the dryer belt, and it may need to be replaced as well. Be sure to disconnect power from the dryer before you begin this repair. This motor pulley is a genuine OEM part sourced directly from the manufacturer.

Replacing your Kenmore Dryer Motor Pulley

Customer Repair Stories

Broken Motor Pulley

-

Anthony from Lake Forest, CA

-

Difficulty Level:Very Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

Broken Motor Pulley

-

Mark from PELHAM, MA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Socket set

This clamp is used to secure the drive motor.

Customer Repair Stories

Dryer drum wouldn't turn and motor would shut off

-

Cynthia M from Westfield, MA

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers