Parts That Fix General Electric Dryer DPSR473EW0WW Marks left on clothes

Marks left on clothes is a commonly reported symptom for the DPSR473EW0WW General Electric Dryer, and we have put together a full guide on how to fix this. This advice is based on feedback from people who own this exact appliance. We have listed the most common parts for your DPSR473EW0WW General Electric Dryer that will fix Marks left on clothes. We have included repair instructions, and helpful step-by-step video tutorials. If you are experiencing this issue, not to worry, DIYers just like you have fixed this, and shared their experience to help you!

This authentic, white Drum Bearing Slide, also known as the bearing drum slide, glide, or pad, is a plastic, easy-to-install part for your dryer. It replaces the dryer's front drum slide to allow for easier movement. You'll know if this part is an issue if your dryer is unable to tumble properly or is very noisy. Damage can come from regular use. The part attaches to the outermost side of the bearing. Check both slides for signs of wear, because they often wear at the same rate, and should be replaced at the same time; there are 2 of these particular slides per dryer. This part is sold individually, so you'll need to purchase multiple parts if replacing both at the same time.

Replacing your General Electric Dryer Drum Bearing Slide - White (Sold individually)

Customer Repair Stories

Replaced Drum Bearing Front And Rear

-

philip from pickens, SC

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

The Front Drum Glides wore out

-

Al from Elmhurst, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

This original equipment manufacturer Drum Bearing Slide is a plastic, green, easy-to-install part for your dryer. It replaces the dryer's front drum slide to allow for easier movement. You'll know if this part is an issue if your dryer is unable to tumble properly or is very noisy. Damage can come from regular use. As the slides start to break down it may cause your dryer to make noise or not dry clothes in the usual amount of time. You will need to purchase two for both sides of your dryer. They attach to the outer-most sides of the bearing. The manufacturer recommends replacing both slides at the same time. Take this opportunity to clean out the lint and dust in the dryer, to keep it running smoothly. This is a genuine replacement part that comes directly from the manufacturer. This item is sold individually. The part attaches to the outermost side of the bearing. Although this part is denoted as being "Green" in its title, many users and technicians have noted that its true colour is closer to a dark gray or black.

Replacing your General Electric Dryer Drum Bearing Slide - Green (Sold individually)

Customer Repair Stories

Squealing as drum rotated

-

Bill from COMSTOCK PARK, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Dryer starts squeaking while operating

-

David from Littleton, CO

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

This Front Drum Bearing (Top Bearing, Dryer Drum Front Support Bearing, Drum Support Bearing, Dryer Drum Glide Bearing) holds the drum bearing and slides for the drum to turn on. The front drum bearing attaches onto the inside of the dryer front panel. When this part fails, the drum may no longer turn freely, make odd sounds, and not dry properly due to the drum no longer sealing. This part needs to be replaced if it is broken (often due to normal wear and tear), no longer able to hold the drum bearing slide securely, or has been eroded by the drum movement. This part is about 10 inches in height and 22 inches in width, and comes in white plastic. Sold individually.

Replacing your General Electric Dryer Front Drum Bearing

Customer Repair Stories

Dryer was not heating at any level and it was making noise while rotating

-

Robert from Louisville, KY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

My dryer was especially noisy like a constant squeeking sound.

W ... Read more rong again... after a few weeks the squeeking continued until I ordered the new drum bearing and replaced the worn one with the new one. I was able to re-use the previous teflon wer strips, and it's like new now at least the squeaks are gone,

The actual fix was a very simple remove old drum bearing, snap in new drum bearing install old teflon wear strips put four screws in top, and front panel and I was back in business

-

Mark from Yorkville, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

This is a duct felt seal for a dryer. The duct felt seal allows the front-load dryer drum to glide smoothly on the front panel. Your dryer will not function properly if the drum felt seal is compromised. Disconnect power to the dryer before completing this repair. You will need to remove the front of the dryer to gain access to the felt seal. This felt seal may differ in appearance from your original but will function the same as your original. This is an OEM replacement part that is sourced directly from the authentic manufacturer.

Replacing your General Electric Dryer Duct Felt Seal

Customer Repair Stories

Dryer leaving stains on clothes

-

Tahir from ARLINGTON, MA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

the felt in front door worn out

-

gerard from goldsboro, NC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

The lint chute assembly houses the lint filter and channels exhaust air from the drum to the blower wheel.

Replacing your General Electric Dryer Dryer Lint Chute Assembly

Customer Repair Stories

Broken piece

-

Kevin from GALES FERRY, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Catching clothing and reping

-

Jose from LILBURN, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

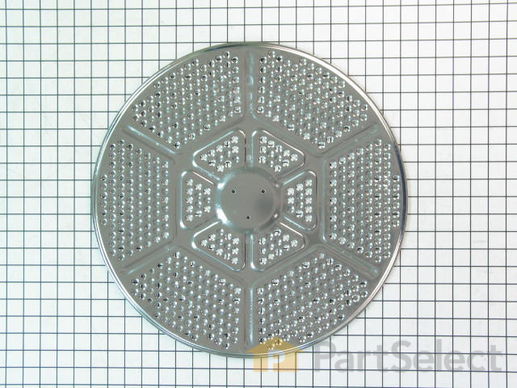

Also known as Drum Mounting Hub.

Customer Repair Stories

Heat deflector was covered in melted plastic

-

Charles from Alexandria, VA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

Deflector was covered in burnt something.

Had I had the proper tools the repair would probably have taken 30 minutes or less.

-

Richard from San Antonio, FL

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Wrench set

This rear drum bearing kit includes a shaft, ground strap, bearing, seven screws, and installation instructions. The bearing plate comes with a slot in it for the ground strap. This part helps keep your dryer running as smoothly as possible with as little noise as possible by supporting the back of the dryer drum and reducing friction as the drum rotates. Over time, your drum bearing will wear out, cause your dryer to be noisy, and you will have to replace it. There may be some sharp internal parts, so be sure to wear work gloves during repair.

Replacing your General Electric Dryer Rear Drum Bearing Kit

Customer Repair Stories

Dryer squeaked when running

Remove the two screws holding the top down.

Disconnect two wires from door switch.

Remove the two hex screws holding the front on.

Remove the 4 screws holding the access panel on the back and disengage idler pulley to loosen the belt.

Remove the drum.

Label the wi ... Read more res then remove the heating element.

Check orientation of ground strap before disassembling rear bearing.

Remove four screws holding rear bearing to back of heating element.

Install rear bearing and ground strap on to heating element.

Reinstall heating element.

Reconnect wires.

Most Important : Get help putting parts back on drum! I didn't and that's why it took over 2 hours.

I will describe how I did it.

Unscrew bearing from inside of drum.

Wrap screwdriver with tape to a little larger than the screw hole.

Use small screwdriver to line up the drum, shim and deflector.

Don't forget the brass shim. It wasn't on the parts diagram.

Start two screws don't tighten them yet.

Remove Screwdriver and start third screw. Tighten all three down.

Put belt on drum.

Install drum and belt.

Reverse disassembly.

When putting the front on make sure drum rests in the felt.

I rated this a bit difficult because I did it myself. With help this is a fairly easy repair.

-

Mark from Garrett, IN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

Squeaking Dryer - Rear Drum bearing gone bad

-

Jason from Cary, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

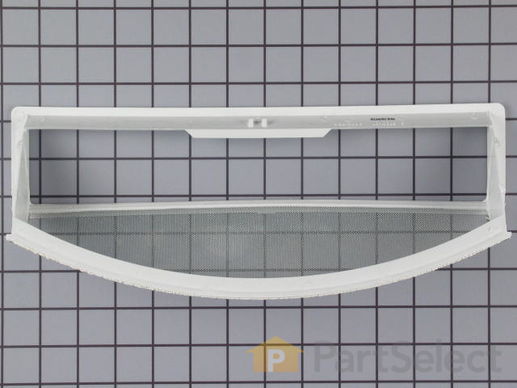

This is a lint filter screen that is used for many dryers. It has a metal screen with a white plastic frame, and is approximately 13 inches wide. This part is sold individually. The lint filter traps lint while clothes are being dried and prevents the lint from building up in clothes and internal parts of your appliance. Neglecting to clean your filter on a regular basis can negatively affect the operation of your dryer and is also a fire hazard. Be sure to clean your filter on a regular basis. Installation is easy, simply slide the filter in and out of the filter slot.

Customer Repair Stories

new lint filter

dryer that is at least 10y/o. it came to me by FEDEX,

in 3 days. i threw out the old one and put in the new

one. easy peasy. i will say that this website had what i

wanted and got it to me very quickly. good job by

PARTSELECT......

-

william from simi valley, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

replacement of holed lint screen

-

Mark from Clarksville, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins