Parts That Fix General Electric Dryer DBXR453EA1WW Noisy

Noisy is a commonly reported symptom for the DBXR453EA1WW General Electric Dryer, and we have put together a full guide on how to fix this. This advice is based on feedback from people who own this exact appliance. We have listed the most common parts for your DBXR453EA1WW General Electric Dryer that will fix Noisy. We have included repair instructions, and helpful step-by-step video tutorials. If you are experiencing this issue, not to worry, DIYers just like you have fixed this, and shared their experience to help you!

This authentic, white Drum Bearing Slide, also known as the bearing drum slide, glide, or pad, is a plastic, easy-to-install part for your dryer. It replaces the dryer's front drum slide to allow for easier movement. You'll know if this part is an issue if your dryer is unable to tumble properly or is very noisy. Damage can come from regular use. The part attaches to the outermost side of the bearing. Check both slides for signs of wear, because they often wear at the same rate, and should be replaced at the same time; there are 2 of these particular slides per dryer. This part is sold individually, so you'll need to purchase multiple parts if replacing both at the same time.

Replacing your General Electric Dryer Drum Bearing Slide - White (Sold individually)

Customer Repair Stories

Replaced Drum Bearing Front And Rear

-

philip from pickens, SC

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

The Front Drum Glides wore out

-

Al from Elmhurst, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

This original equipment manufacturer Drum Bearing Slide is a plastic, green, easy-to-install part for your dryer. It replaces the dryer's front drum slide to allow for easier movement. You'll know if this part is an issue if your dryer is unable to tumble properly or is very noisy. Damage can come from regular use. As the slides start to break down it may cause your dryer to make noise or not dry clothes in the usual amount of time. You will need to purchase two for both sides of your dryer. They attach to the outer-most sides of the bearing. The manufacturer recommends replacing both slides at the same time. Take this opportunity to clean out the lint and dust in the dryer, to keep it running smoothly. This is a genuine replacement part that comes directly from the manufacturer. This item is sold individually. The part attaches to the outermost side of the bearing. Although this part is denoted as being "Green" in its title, many users and technicians have noted that its true colour is closer to a dark gray or black.

Replacing your General Electric Dryer Drum Bearing Slide - Green (Sold individually)

Customer Repair Stories

Squealing as drum rotated

-

Bill from COMSTOCK PARK, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Dryer starts squeaking while operating

-

David from Littleton, CO

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

This Front Drum Bearing (Top Bearing, Dryer Drum Front Support Bearing, Drum Support Bearing, Dryer Drum Glide Bearing) holds the drum bearing and slides for the drum to turn on. The front drum bearing attaches onto the inside of the dryer front panel. When this part fails, the drum may no longer turn freely, make odd sounds, and not dry properly due to the drum no longer sealing. This part needs to be replaced if it is broken (often due to normal wear and tear), no longer able to hold the drum bearing slide securely, or has been eroded by the drum movement. This part is about 10 inches in height and 22 inches in width, and comes in white plastic. Sold individually.

Replacing your General Electric Dryer Front Drum Bearing

Customer Repair Stories

Dryer was not heating at any level and it was making noise while rotating

-

Robert from Louisville, KY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

My dryer was especially noisy like a constant squeeking sound.

W ... Read more rong again... after a few weeks the squeeking continued until I ordered the new drum bearing and replaced the worn one with the new one. I was able to re-use the previous teflon wer strips, and it's like new now at least the squeaks are gone,

The actual fix was a very simple remove old drum bearing, snap in new drum bearing install old teflon wear strips put four screws in top, and front panel and I was back in business

-

Mark from Yorkville, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

This is a duct felt seal for a dryer. The duct felt seal allows the front-load dryer drum to glide smoothly on the front panel. Your dryer will not function properly if the drum felt seal is compromised. Disconnect power to the dryer before completing this repair. You will need to remove the front of the dryer to gain access to the felt seal. This felt seal may differ in appearance from your original but will function the same as your original. This is an OEM replacement part that is sourced directly from the authentic manufacturer.

Replacing your General Electric Dryer Duct Felt Seal

Customer Repair Stories

Dryer leaving stains on clothes

-

Tahir from ARLINGTON, MA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

the felt in front door worn out

-

gerard from goldsboro, NC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

This rear drum bearing kit includes a shaft, ground strap, bearing, seven screws, and installation instructions. The bearing plate comes with a slot in it for the ground strap. This part helps keep your dryer running as smoothly as possible with as little noise as possible by supporting the back of the dryer drum and reducing friction as the drum rotates. Over time, your drum bearing will wear out, cause your dryer to be noisy, and you will have to replace it. There may be some sharp internal parts, so be sure to wear work gloves during repair.

Replacing your General Electric Dryer Rear Drum Bearing Kit

Customer Repair Stories

Dryer squeaked when running

Remove the two screws holding the top down.

Disconnect two wires from door switch.

Remove the two hex screws holding the front on.

Remove the 4 screws holding the access panel on the back and disengage idler pulley to loosen the belt.

Remove the drum.

Label the wi ... Read more res then remove the heating element.

Check orientation of ground strap before disassembling rear bearing.

Remove four screws holding rear bearing to back of heating element.

Install rear bearing and ground strap on to heating element.

Reinstall heating element.

Reconnect wires.

Most Important : Get help putting parts back on drum! I didn't and that's why it took over 2 hours.

I will describe how I did it.

Unscrew bearing from inside of drum.

Wrap screwdriver with tape to a little larger than the screw hole.

Use small screwdriver to line up the drum, shim and deflector.

Don't forget the brass shim. It wasn't on the parts diagram.

Start two screws don't tighten them yet.

Remove Screwdriver and start third screw. Tighten all three down.

Put belt on drum.

Install drum and belt.

Reverse disassembly.

When putting the front on make sure drum rests in the felt.

I rated this a bit difficult because I did it myself. With help this is a fairly easy repair.

-

Mark from Garrett, IN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

Squeaking Dryer - Rear Drum bearing gone bad

-

Jason from Cary, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

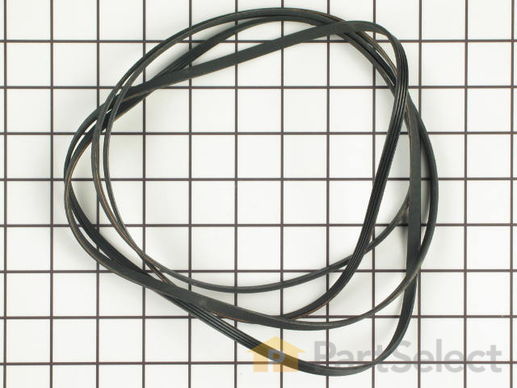

This Drive Belt is 89.5" long and comes in black, featuring four ribs on the inside for a better grip. This is a long belt that wraps all the way around the dryer drum, around a tension pulley, and then around the drive motor pulley, allowing all the parts to work together, spinning the drum as the motor rotates. If the drum will not turn when the dryer is turned on the belt is likely broken. It is common for belts to stretch or become brittle over time, which is what leads to the breakage. If broken, it should be replaced; the drum simply cannot spin without this belt. Refer to your model number and user manual to check if this part is right for you. Ensure you use work gloves to protect your hands from sharp internal parts during this repair. Please note: When comparing the length of your old belt to the length of the belt as stated here, remember that a small amount of stretching and contortion may occur with belts over time for a range of different reasons. Unless your belt is drastically different in length, this belt is what you are looking for despite any small inaccuracies. You will need to remove power to your appliance, remove the main panel, and access the motor drive to slip your new belt back into place.

Replacing your General Electric Dryer Drive Belt

Customer Repair Stories

Broken Dryer Belt

-

Richard from Ashton, MD

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

Drum belt broke

This was a first attempt ever at fixing an appliance and it was no big deal.

-

Adrian from Middletown, MD

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

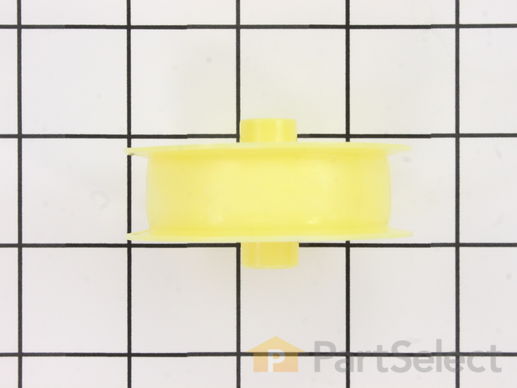

A dryer's idler pulley wheel serves to help the belt to rotate the drum.

Replacing your General Electric Dryer Idler Pulley Wheel

Customer Repair Stories

Replace broken drum belt and belt idler pully wheel.

-

David from EASTON, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

belt broken, pulley worn out

-

Anthony from Mpls, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Socket set

Sold individually.

Replacing your General Electric Dryer Drum Bearing Sleeve

Customer Repair Stories

Loud noise

-

Mary from Enterprise, AL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Rubbing/Squealing Noise While Drying, especially during cold weather

Our dryer was making a very annoying squeaking/rubbing noise while drying and it became worse as the outside temps dropped (it's winter)...colder air cooling the exhaust line, causing metal in dryer to contract more.

... Read more >I called an appliance repair service and they said, "Honestly, your money is going to be better spent to just buy a new dryer. The bearings on these are a pain to replace."

Yeah, right.

I've never taken apart a dryer, but it took me less than 45 minutes to complete this repair and our dryer is back to normal. Total cost was $18, including shipping. A $300 savings versus buying a new dryer.

There is another description of the process for this part so I won't repeat it all.

I did it a little differently than most, namely I did not remove the dryer drum. I simply pulled it out about six inches (make sure and slide belt back as you inch out the drum). But first, unplug the dryer, then remove the top, then the front.

A Philips screwdriver will quickly remove the top of the dryer (two screws on inside front, where door closes) and the front face (two screws at top of front, inside face). Lift the front up about an inch and it is free. I had to disconnect a couple wires, just make sure you mark before you disconnect them.

With that done, the drum will pull straight toward you (out). Make sure and support the weight of the drum as you slide it out. I found no need to remove the drum.

At the rear inside of our drum, there are three Torx screws that hold the bearing assembly on. I have a pretty long reach so I just removed two of the Torx screws, then reached around the back of the drum while removing the third screw, to keep the bearing assembly from falling onto the floor behind the back of the drum.

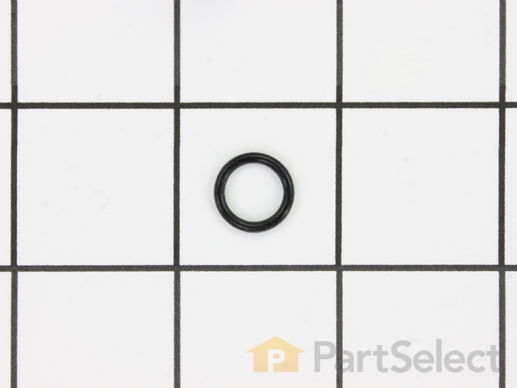

This plastic bearing is held to the bearing shaft by a little o-ring. Just pull the o-ring off, slide off the old bearing, slide the new bearing on and replace the o-ring (if yours is broken, any home store will have one that will work as a replacement in their faucet repair department).

Reattach the bearing housing to the drum with the Torx screws (get all three started before you tighten any of them), slide the drum back in - make sure you slide the belt as you move the drum back in and support the weight of the drum so you don't bash the bearing assembly into the back of the dryer.

You're doing this part blind, but in a few seconds, you can guide the bearing back into the hole in the back wall of the dryer. It just slides into the hole, nothing fancy.

Put the front of the dryer back on. Then replace the top (I had to remove the five screws on top of the dial panel to give it some flex so the top would pop back into place without stressing the dial panel), plug the dryer back in, and fire it up.

45 minutes after this part arrived at our home, our dryer problems were gone. Now that I've done one, I could probably do it in 20 minutes the next time (it's that simple/easy). And we didn't need a new dryer. Makes me think I should have the appliance guy who told me we needed a new dryer to direct all of these "pain in the fanny" bearing replacements to me because I could charge someone $50 total for the repair and make good money.

Hope all this babble helps someone else who doesn't need a new dryer.

-

Gary from Spring Hill, TN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

This is a replacement O-ring for the drum bearing retainer on your dryer. The drum bearing is found at the back of the dryer drum. The O-ring is designed to create a seal on the drum bearing. The O-ring is made of rubber, and can occasionally wear down and break. If you notice that your dryer drum bearing is worn while you’re replacing the O-ring, you should consider replacing it as well. This product is sold individually, and is an OEM part from the manufacturer.

Replacing your General Electric Dryer Retainer O-Ring

The lint chute assembly houses the lint filter and channels exhaust air from the drum to the blower wheel.

Replacing your General Electric Dryer Dryer Lint Chute Assembly

Customer Repair Stories

Broken piece

-

Kevin from GALES FERRY, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Catching clothing and reping

-

Jose from LILBURN, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

This is 39 inches long.

Customer Repair Stories

WAITING ON PART

-

MARTIN from MOUNTAIN VIEW, WY

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

This wheel attaches to the motor.

Replacing your General Electric Dryer Blower Wheel

There is a slot in it for a ground strap.

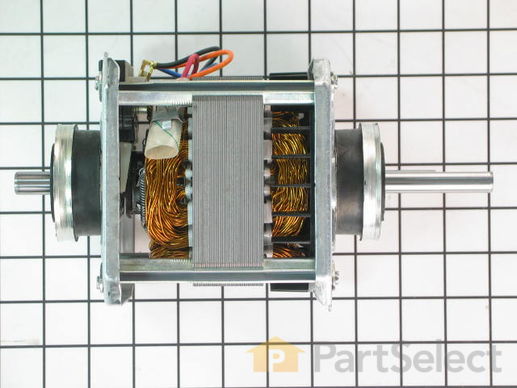

This part, along with the idler pulley wheel, helps the belt to rotate the drum.

Replaces "T" and "V" style motors. Includes two motor pulleys. If you have an older model dryer, the pulley may be pressed on or held on with a set screw. If pulley is pressed on, a new motor pulley must be ordered.

Customer Repair Stories

The main symptom was a burning smell that got on the clothes and the dryer was somewhat louder than it had been.

-

Kristin from Bellevue, WA

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

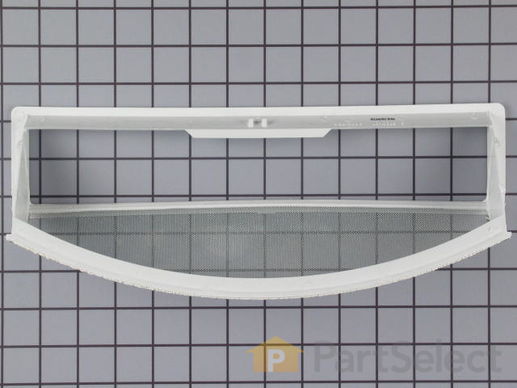

This is a lint filter screen that is used for many dryers. It has a metal screen with a white plastic frame, and is approximately 13 inches wide. This part is sold individually. The lint filter traps lint while clothes are being dried and prevents the lint from building up in clothes and internal parts of your appliance. Neglecting to clean your filter on a regular basis can negatively affect the operation of your dryer and is also a fire hazard. Be sure to clean your filter on a regular basis. Installation is easy, simply slide the filter in and out of the filter slot.

Customer Repair Stories

new lint filter

dryer that is at least 10y/o. it came to me by FEDEX,

in 3 days. i threw out the old one and put in the new

one. easy peasy. i will say that this website had what i

wanted and got it to me very quickly. good job by

PARTSELECT......

-

william from simi valley, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

replacement of holed lint screen

-

Mark from Clarksville, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Customer Repair Stories

Rusty door

-

David from Newport, AL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

The selector knob is what you use to start the dryer. This replacement knob comes with a retaining clip. This is a very easy repair, the only tool you may need is a pair of needle nose pliers. Remove the existing knob by pulling it off, making sure to remove the retaining clip as well. Line up the new knob with the D-shaped shaft and slide it into place.

Replacing your General Electric Washer Selector Knob with Clip

Customer Repair Stories

The inside of the Selector Knob was stripped

-

Frank from Irvine, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Replaced broken START knob on dryer.

I created and printed a label on my computer for use with the time selector dial, which must be set at or beyond 10 minutes, before turning the START knob.

I made a label that says "Minimum" with a red arrow that points past the 10 minute setting on the ... Read more time selector dial.

My teenage daughter was not setting the time selector dial, to a point past 10 minutes. When she turned the START knob, the dryer would not come on, because the time selector dial was not set past the 10 minute setting.

My daughter had continually twisted the START knob until it broke. I am hoping she will be able to see the large printed label I put on the dryer near the time selector, saying "Minimum" with a large red arrow pointing past 10 minutes.

I am very pleased that I was quickly able to find the exact matching START knob for my dryer and the exact same color, from PartSelect.Com

-

SAM from ROCK HILL, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins