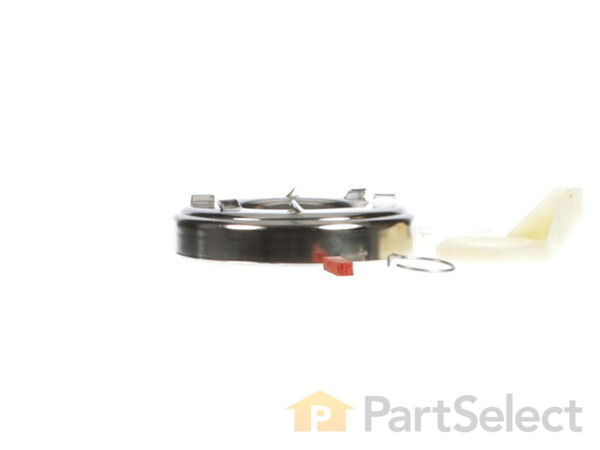

Clutch Assembly 285785

Rated by 69 customers

Easy

1- 2 hours

Ratings submitted by customers like you who bought this part.

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

Clutch Assembly Specifications

How Buying OEM Parts Can Save You Time and Money

Replacing your Whirlpool Washer Clutch Assembly

-

5 Stars 67

-

4 Stars 8

-

3 Stars 2

-

2 Stars 0

-

1 Star 1

- < Prev

- 1

- 2

- 3

- Next >

- < Prev

- 1

- 2

- 3

- Next >

- < Prev

- 1

- 2

- 3

- Next >

-

Richard from EL SEGUNDO, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Socket set

-

GREGG from LIVONIA, MI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

-

Neil from Winfield, IL

-

Difficulty Level:Very Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

-

Richard from WEEKI WACHEE, FL

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

-

Jonathan from BRANDON, VT

-

Difficulty Level:Really Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

-

eugene from abbott, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Lou from ATLANTIC HLDS, NJ

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

-

Mark from CHARLOTTE, NC

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable)

-

JOHN from MUSKEGON, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

-

david from WEBSTER, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

- < Prev

- 1

- 2

- 3

- Next >

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- 3

- Next >

65 people found this helpful.

18 people found this helpful.

11 people found this helpful.

11 people found this helpful.

6 people found this helpful.

5 people found this helpful.

5 people found this helpful.

5 people found this helpful.

4 people found this helpful.

4 people found this helpful.

- < Prev

- 1

- 2

- 3

- Next >

Manufacturer Part Number: 285785

Item is in stock and will ship today if your order is placed before 4:00 PM Eastern Standard Time.

If your order is placed after 4:00 PM EST, the in stock items will ship on the next business day.

Item is not in stock and usually ships 3-5 business days from the time you place your order.

Item is not in stock and usually ships 10-15 business days from the time you place your order.

This item is no longer being made by the manufacturer, and cannot be added to your shopping cart.