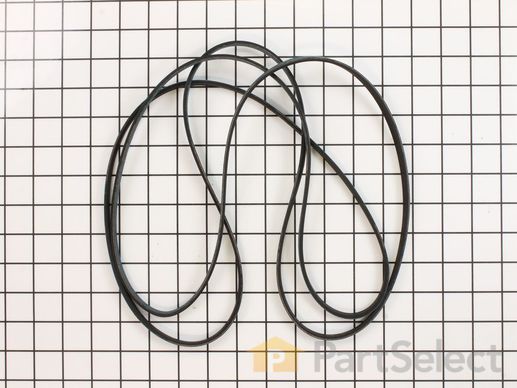

Multi Rib Belt WP40111201

Rated by 115 customers

Easy

1- 2 hours

Ratings submitted by customers like you who bought this part.

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

Multi Rib Belt Specifications

How Buying OEM Parts Can Save You Time and Money

Replacing your Amana Dryer Multi Rib Belt

-

5 Stars 84

-

4 Stars 14

-

3 Stars 2

-

2 Stars 2

-

1 Star 1

- < Prev

- 1

- 2

- 3

- Next >

- < Prev

- 1

- 2

- 3

- Next >

- < Prev

- 1

- 2

- 3

- Next >

Longest part was cleaning the inside of dryer and cutting new vent pipe exit.

-

Steven from MORRIS, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Wrench (Adjustable), Wrench set

-

Joseph from LAGRANGE, IN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

-

Paul from BUFORD, GA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

-

JAMES from SPRING, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Wrench (Adjustable)

have a little grease available when you install the new idler lever (between the arm and the bolt area as it constantly moves and the old brease has probably worn away) . After making these repairs I dont think I will ever buy a new dryer as any part , including the heater and motor would be easy to replace and cheaper than a new dryer.

-

Paul from LITTLETON, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

-

Raymond from OCEANSIDE, NY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

-

Kathy from Anderson, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

-

Richard from PORTLAND, OR

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

-

Steven from ROSEVILLE, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

-

Joseph from GREENWICH, CT

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

- < Prev

- 1

- 2

- 3

- Next >

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- Next >

17 people found this helpful.

10 people found this helpful.

10 people found this helpful.

7 people found this helpful.

6 people found this helpful.

5 people found this helpful.

2 people found this helpful.

1 person found this helpful.

1 person found this helpful.

1 person found this helpful.

- < Prev

- 1

- 2

- Next >

Manufacturer Part Number: WP40111201

Item is in stock and will ship today if your order is placed before 4:00 PM Eastern Standard Time.

If your order is placed after 4:00 PM EST, the in stock items will ship on the next business day.

Item is not in stock and usually ships 3-5 business days from the time you place your order.

Item is not in stock and usually ships 10-15 business days from the time you place your order.

This item is no longer being made by the manufacturer, and cannot be added to your shopping cart.