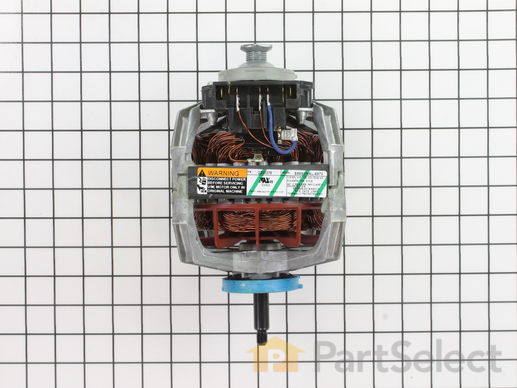

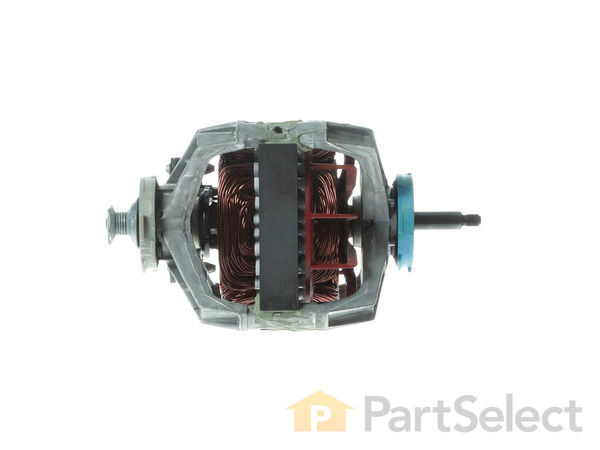

Motor Assembly - Threaded Shaft WP2200376

Rated by 18 customers

Easy

1- 2 hours

Ratings submitted by customers like you who bought this part.

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

Motor Assembly - Threaded Shaft Specifications

How Buying OEM Parts Can Save You Time and Money

-

5 Stars 8

-

4 Stars 0

-

3 Stars 1

-

2 Stars 0

-

1 Star 0

- < Prev

- 1

- Next >

- < Prev

- 1

- Next >

- < Prev

- 1

- 2

- Next >

Unfortunately, although PartSe ... Read more lect provides a video for just about every part they sell, they do not have a video for replacing the motor. However, they do provide a video for replacing the Dryer Idle Level which is attached to the motor, and I suggest watching this video to help remove the motor for replacement.

https://youtu.be/8AtOYoABVp0

Some tips while disassembling the dryer that will help with reassembly: Bring your cell phone. I watched the video in full, then watched step by step as I took the dryer apart. Take pictures of where wires are connected so you can reconnect them properly. A majority of the bolts you remove will use the same size socket, but are different. Be sure to separate them so you don't get them mixed up. I used a magnetic bowl and clumped them together. Have a vacuum handy for all the dust bunnies that have accumulated. Finally, while they may not be broken now, I ordered a new belt, drum wheels, and Idler, and replaced them while I had the dryer apart. Might as well replace these items that eventually fail while you are there since they are not that expensive. I ordered a kit that contained all 3 from another vendor, but you can find them here with videos for instillation.

Once you have the motor removed as shown in the video linked above, you will have to remove the metal shield covering the fan. Then using a socket wrench on the attachment of the fan itself, and another wrench to hold the pulley nut if it is attached, or vice grips on the shaft if it is stripped like mine, loosen the fan from the motor. It is a reverse screw pattern, so be sure to loosen in the direction that is indicated on the fan itself so not to break the fan which is plastic. Once the fan is removed, you will see two clamps holding the motor to the base, Use a flat head screw driver to push down on one side of the clamp, then leverage it off. After removing both clamps, squeeze the edges of the wiring harness and remove it. With a slight turn to of the motor it will come free of the base. Replace it with the new one insuring it is label side up, then reassemble in reverse. Wiring harness, clamps, fan, ect.

The video link above will give instructions for reassembling the dryer and attaching the belt. Good luck.

-

Scott from AIKEN, SC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

-

JAMES from SPRING, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Wrench (Adjustable)

-

steven from HOLMEN, WI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Socket set

-

Michael from North Hampton, NH

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

-

Randal from Centralia, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

-

Ernest from Ida, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

-

Robert from Kellogg, IA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

-

Caroline from Rockland, ME

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers

Then there are two screws inside that fasten the front to the rest of the frame. Once I removed these, and the electrical connections to the door switch and the light bulb, the whole front came of just by tilting it forward and pulling the front panel up off of metal tabs on the base.

The rest of the repair went smoothly per other descriptions.

-

Gregory from Holland, MI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench (Adjustable)

Replace Bulheald and door panel [re-attach door switch wires].Complete install by lifting belt pulley and feeding new belt into place. Hand rotate drum to ensure proper belt allignment and tracking. Replace lower panel. Vacuum interior as necessary. Parts delivered in 3days and fit perfectly.

-

Gregory from Virginia Beach, VA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench (Adjustable)

- < Prev

- 1

- 2

- Next >

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- Next >

27 people found this helpful.

15 people found this helpful.

5 people found this helpful.

5 people found this helpful.

3 people found this helpful.

2 people found this helpful.

2 people found this helpful.

2 people found this helpful.

2 people found this helpful.

- < Prev

- 1

- 2

- Next >

Manufacturer Part Number: WP2200376

Item is in stock and will ship today if your order is placed before 4:00 PM Eastern Standard Time.

If your order is placed after 4:00 PM EST, the in stock items will ship on the next business day.

Item is not in stock and usually ships 3-5 business days from the time you place your order.

Item is not in stock and usually ships 10-15 business days from the time you place your order.

This item is no longer being made by the manufacturer, and cannot be added to your shopping cart.