ZEK737BA3BB General Electric Wall Oven - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Oven tempature was approximately 150 degrees to low

This repair is EASY if you know how to use an ohm meter. If not, seek help for this step.

SYMPTOM:

The oven (JKP27WOP3WG or JKP27WP3WG and many ovens like it ) was not getting hot enough. Verifying the cooking temperature with an typical oven thermometer, I was able to determine that the oven was cooking temperature was about 150 degrees to low.

FAILURE POINTS:

There are two logical failure points (1) The oven sensor ( WB21X5301 about $75), or the (2) the controller board (PS238233 about $252). In my case it was the controller board. When replaced the oven worked beautifully.

REPAIR:

As with any repair, you MUST DISCONNECT POWER TO THE UNIT BEFORE SERVICING!!!

Pull oven from the wall:

- Disconnect power by flipping the circuit breaker to the OFF position.

- Remove the top flange / cowling from the top of the oven (it just pulls off)

- Remove two screws under the top flange / cowling

- The whole unit easily slides out, but it is highly recommended that you use two people to place the oven on the floor.

As a diagnostic between these two parts, if the oven sensors measure approximately 1.1K ohms of resistance at room temperature, then it is probably not the sensor. The oven sensor wires are connected to two white wires that run up to the controller board. You need to disconnect the oven sensor to make the measurement. You may either completely remove the oven sensor by cutting the wire (be sure to allow yourself enough slack so that they may be safely reconnected) where it connects to the white wires, OR, (preferred method) if leaving the oven sensor partially installed,

- Remove the top sheet metal cover (10 screws)

- Remove the service connect cover (2 screws - this is where the main Power cord comes into the unit)

- Disconnect the white wires from the controller board (this connector which also includes other circuits is on the left side when looking at the controller board).

- Remove two screws from oven sensor but just let in dangle down so that you can put the sensor in the ice water / boiling water.

Measure the resistance under the following conditions. Your ohm meter should read APPROXIMATELY...

- 1.02K ohms in ice water

- 1.09K ohms at room temperature

- 1.36K ohms in boiling water.

If you get approximately these readings, then it is NOT the oven sensor. If that checks out then re-install the sensor AND the connector.

If it is NOT the sensor, replace the controller board.

- Take a moment to write down the color of the wire to the LETTERING (N, L, G, C / COM,,,) on the controller board. The connectors are in different locations on the new controller board so the wire color to the letter designation is significant.

- Carefully remove the wires one at a time

- VERY carefully remove the keypad ribbon cable from the right side of the controller board.

-- The ribbon cable will disconnect by releasing some little pressure clips on the side of the connector.

- Remove the controller board (4 screws)

- Install new controller board (4 screws)

- VERY carefully connect the keypad ribbon cable on the right side.

-- Make sure that the connector is in the OPEN position first, then,

-- Slide in the cable ensuring that all parts of the ribbon made it into the connector, then

-- Press down on the connector locking tabs.

- Reconnect each wire to the correctly lettering on the board.

-- Again, the connectors MAY BE in a different order on the replacement controller board. Match color to letter.

- Reconnect the (5 wire?) connector that includes the white oven sensor wires.

- Make sure everything looks normal, (i.e. no wires are pinched, remove tools from top of oven area, etc.)

- Re-install top cover.

- Re-install service connect cover.

You can test the unit while it is out of the cabinet,

- Make SURE that all sheet metal covers are in place.

- Flip power breaker to "On".

- Test that oven gets to the desired temp.

SYMPTOM:

The oven (JKP27WOP3WG or JKP27WP3WG and many ovens like it ) was not getting hot enough. Verifying the cooking temperature with an typical oven thermometer, I was able to determine that the oven was cooking temperature was about 150 degrees to low.

FAILURE POINTS:

There are two logical failure points (1) The oven sensor ( WB21X5301 about $75), or the (2) the controller board (PS238233 about $252). In my case it was the controller board. When replaced the oven worked beautifully.

REPAIR:

As with any repair, you MUST DISCONNECT POWER TO THE UNIT BEFORE SERVICING!!!

Pull oven from the wall:

- Disconnect power by flipping the circuit breaker to the OFF position.

- Remove the top flange / cowling from the top of the oven (it just pulls off)

- Remove two screws under the top flange / cowling

- The whole unit easily slides out, but it is highly recommended that you use two people to place the oven on the floor.

As a diagnostic between these two parts, if the oven sensors measure approximately 1.1K ohms of resistance at room temperature, then it is probably not the sensor. The oven sensor wires are connected to two white wires that run up to the controller board. You need to disconnect the oven sensor to make the measurement. You may either completely remove the oven sensor by cutting the wire (be sure to allow yourself enough slack so that they may be safely reconnected) where it connects to the white wires, OR, (preferred method) if leaving the oven sensor partially installed,

- Remove the top sheet metal cover (10 screws)

- Remove the service connect cover (2 screws - this is where the main Power cord comes into the unit)

- Disconnect the white wires from the controller board (this connector which also includes other circuits is on the left side when looking at the controller board).

- Remove two screws from oven sensor but just let in dangle down so that you can put the sensor in the ice water / boiling water.

Measure the resistance under the following conditions. Your ohm meter should read APPROXIMATELY...

- 1.02K ohms in ice water

- 1.09K ohms at room temperature

- 1.36K ohms in boiling water.

If you get approximately these readings, then it is NOT the oven sensor. If that checks out then re-install the sensor AND the connector.

If it is NOT the sensor, replace the controller board.

- Take a moment to write down the color of the wire to the LETTERING (N, L, G, C / COM,,,) on the controller board. The connectors are in different locations on the new controller board so the wire color to the letter designation is significant.

- Carefully remove the wires one at a time

- VERY carefully remove the keypad ribbon cable from the right side of the controller board.

-- The ribbon cable will disconnect by releasing some little pressure clips on the side of the connector.

- Remove the controller board (4 screws)

- Install new controller board (4 screws)

- VERY carefully connect the keypad ribbon cable on the right side.

-- Make sure that the connector is in the OPEN position first, then,

-- Slide in the cable ensuring that all parts of the ribbon made it into the connector, then

-- Press down on the connector locking tabs.

- Reconnect each wire to the correctly lettering on the board.

-- Again, the connectors MAY BE in a different order on the replacement controller board. Match color to letter.

- Reconnect the (5 wire?) connector that includes the white oven sensor wires.

- Make sure everything looks normal, (i.e. no wires are pinched, remove tools from top of oven area, etc.)

- Re-install top cover.

- Re-install service connect cover.

You can test the unit while it is out of the cabinet,

- Make SURE that all sheet metal covers are in place.

- Flip power breaker to "On".

- Test that oven gets to the desired temp.

Parts Used:

-

James from Austin, TX

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

220 of 258 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

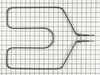

The broiler element caught fire and burned out while I was broiling a steak.

First I removed the two screws that hold the element in place. I then pulled the element out about 3 inches, but I had not turned off the power.

So, I shorted out one of the wires. Then I turned off the power but was afraid to go any farther.

An appliance repairman was at my house that day fixing my dryer seal. He was able to pull the wires through the insulation successfully and install the broiler element. He did not charge me any extra for this little extra job. But I learned my lesson. Cut the power before you begin! He told me that I could have wound up with a much bigger repair if the short had been in the wire that is connected to the control panel of the oven. I was very lucky!

So, I shorted out one of the wires. Then I turned off the power but was afraid to go any farther.

An appliance repairman was at my house that day fixing my dryer seal. He was able to pull the wires through the insulation successfully and install the broiler element. He did not charge me any extra for this little extra job. But I learned my lesson. Cut the power before you begin! He told me that I could have wound up with a much bigger repair if the short had been in the wire that is connected to the control panel of the oven. I was very lucky!

Parts Used:

-

Dianne from Rockville, MD

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

67 of 75 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top broiler element went out

FIRST MAKE SURE THE OVEN IS OFF!!!! I chose to shut it off at the breaker panel. Remove the two screws that attaches the broiler element to the oven. Gently pull it out. Unplug the two cable wires that are attached. Replace it and install the same way.

Parts Used:

-

Kim from Garland, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

39 of 42 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven would not heat to the correct temperature

First I removed the two screws that hold the element in place. I then pulled the element out about 3 inches and disconnected the two wires

Parts Used:

-

Michael from Lawrenceville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

37 of 60 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

F2 error message on my GE oven indicated need for new heat sensor

After unscrewing the old heat sensor from inside the oven, I pulled the range away from the wall, got behind it and removed the small panel over the heat sensor. Naturally, the plastic clips connecting the heat sensor to the range wiring wouldn't come apart, so I eventually had to simply pry them apart with two pliers. Then, naturally, the new plastic connector clip on the replacement part didn't match the clip from the range, so I had to cut off both receptacles and strip the wires, then used the provided wire nuts to make the connections. After that, it was easy, just secured the heat sensor inside the oven and replaced the panel. I didn't push the range back against the wall until I tested the repair. It worked fine!

Parts Used:

-

Joseph from Brick, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

25 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replacement of heating element

If I'd had the Nut driver, it would have taken 15 -20 minutes or less. Went to Ace Hardware, bought the nut driver for $4.99.

Turn off the power at the box! Turn off the oven as well. Four screws total. Two to hold it in place and two that connect the element to the source.

First I removed the two screws that hold the element in place. I pulled the element out about 2 inches. Two more screws connect the element wires. I disconnected the element, threw it away, then connected the new element. I put the element in place, then replaced the screws that connect the power. Finally, I replaced the screws that hold the element in place.

Kimberly, El Cerrito, California

Turn off the power at the box! Turn off the oven as well. Four screws total. Two to hold it in place and two that connect the element to the source.

First I removed the two screws that hold the element in place. I pulled the element out about 2 inches. Two more screws connect the element wires. I disconnected the element, threw it away, then connected the new element. I put the element in place, then replaced the screws that connect the power. Finally, I replaced the screws that hold the element in place.

Kimberly, El Cerrito, California

Parts Used:

-

Kimberly from El Cerrito, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

16 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven stops heating and states F3 error code.

The most obbious suspect is the upper oven fan. Turned off power circuit breaker. Removed two philip screws at top of control panel and lowered the panel. Using the 3D view of the oven on this web site I located the fan limit switch. Jumpered the limit switch. Turned power on and the fan ran. That proved the switch was defective and not the fan. Replaced the limit I purchased from Partselect.com.

Please note* My life career was electrical. I used the schematic that came with the oven to determine that the limit was the only control between one of the 240 volt lines and the fan. Thus I knew it was safe to jump the limit.

If you are in doubt, seek some advice.

Good Luck, Arno

Please note* My life career was electrical. I used the schematic that came with the oven to determine that the limit was the only control between one of the 240 volt lines and the fan. Thus I knew it was safe to jump the limit.

If you are in doubt, seek some advice.

Good Luck, Arno

Parts Used:

-

Arno from Sacramento, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

19 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

oven would not cook over 325 degrees and sometimes would burn your food.

I removed the unit from the wall,removed the back panel to access the wires to the sensor,cut the plug off of the new sensor and strip the wires back,used the wire nuts to attach the new sensor,put all back together and slid back into the wall and works excellent.

Parts Used:

-

phil from forney, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

15 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

oven shut down code F3

As has been said shut down unit,Breaker fuse.If you do not have install info.Get a copy on line. If you have another set of hands it would not hurt.! this has been stated before. Remove door, Remove 4 screws , to slide unit out,I used a saw horse with some cribing secured to the horse to get height, Pull the oven out so that the two front supports are on the saw horse,and the back two are up to the edge runner.I used about a 1 ft stool for working height. Remove the top elec. cover sheet metal 2 screws. You will see were the wireing runs down the back. Get a small mirror,and flash light. Look down the wire opening in the back, you see the sensor connection ,I made a hook out of a coat hanger to grab it with. Pull it up before you disconnect it ,tie a piece of string to the sensor side of the connector , use 2 Ft. then disconnect remove two screws from inside the oven. And remove,sensor tie string on to new sensor connector pull through and connect.on top.Then replace everything cck every thing Twice!Doing this i didn"t have to pull the unit all the way out! LATER GOOD LUCK!

Parts Used:

-

Richard from Jupiter, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

17 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broiler element would not heat; bake element did heat

Removed the oven racks, removed screws holding element hanging support from roof of oven, removed screws holding plate of element to rear of oven. CAREFULLY worked element loose from back of oven and gently alternated pulling each side of element (near the base) until connecting wires came free of insulating batting. Pull too hard and the connecting wires can break loose and disappear behind the batting. Once freed, disconnected both wires with socket (use pliers for extra grip on flat part of connectors, if necessary), removed element, braced new element on bottom of oven, aligning connectors to now-free wires. Re-attached with the new screws that came with the element (attachment points on element are threaded; do not reuse old screws as the threads may not match), gently re-inserted element into insulating batting at rear of oven, reattached hanging support, then replaced element plate screws.

Can be difficult to work in small, deep ovens....many oven doors can be removed. If so, remove oven door and use a chair as a support...lie on your back on the chair and hang your head and arms in the oven.

Can be difficult to work in small, deep ovens....many oven doors can be removed. If so, remove oven door and use a chair as a support...lie on your back on the chair and hang your head and arms in the oven.

Parts Used:

-

Brad from San Carlos, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

12 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven not heating

It was very easy I removed two screws unpluged the sensor and wire spliced it together and also replaced the modual on the top of the stove and it was that easy.

Parts Used:

-

Joseph from Stuart, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

14 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Heating element dangling

-

Victor from Miami Beach, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven would not maintain set temperature

No problem installing oven sensor, but I diagnose the problem wrong, I need to change(ERC-11)control p/n wb27k5140

Parts Used:

-

Leonel from Biddeford, ME

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

11 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The upper element for broiling went kaput!

The two dollar socket set from Xmas 20 years ago had the right size socket..

Long arms are advisable.

The lower element still plugged in while the upper wires were just hanging there surrounded with fluffy white insulation fuzz, I wondered, " Could I bake a potato for my yearning and hungry family?"

When I explained the situation to my retired father in Arizona he said simply, "I wouldn't."

The new element popped in. It got really red, and, kinda like watching my toaster toast, the show was pretty much over after it heated up.

Shalom and Merry Christmas Folks!

Long arms are advisable.

The lower element still plugged in while the upper wires were just hanging there surrounded with fluffy white insulation fuzz, I wondered, " Could I bake a potato for my yearning and hungry family?"

When I explained the situation to my retired father in Arizona he said simply, "I wouldn't."

The new element popped in. It got really red, and, kinda like watching my toaster toast, the show was pretty much over after it heated up.

Shalom and Merry Christmas Folks!

Parts Used:

-

Gerald from Redondo Beach, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

8 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Single Heating Element Support Clip was needed to hold up the heating element in the oven. Old single heating element support clip broke and came out of the hole.

Simply inserted the clip into the hole in the oven. It took less than 20 seconds. :D

Parts Used:

-

Marion from METHUEN, MA

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

6 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!