WWS833FS1 Westinghouse Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

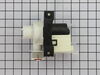

Washing machine wouldn't drain

i removed the front panel, then removed the old pump by taking off the clamps and disconnected the wiring. The new pump had to be reversed before connecting, but it was so easy.

Parts Used:

-

Siobhain from Ashland, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

11 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Tub was leeking

Lifted top

removed adgetator

removed tub top

removed inside tub

removed inside tub holder bracket

repaced seal

replaced,replaced.....

removed adgetator

removed tub top

removed inside tub

removed inside tub holder bracket

repaced seal

replaced,replaced.....

Parts Used:

-

Gregory from Fort Worth, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

13 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer went into spin mode but would not spin

I removed the front panel to see the belt was snapped in two. The front roller is sping loaded, so I gave it a little tention, slid the belt back on and viola! it was that easy. If your washer starts to vibrate more and sounds louder than normal, get a belt as soon as possible because that may be the problem. Once I put on the new belt, the machine ran as quiet as it did when I first bought it.

Parts Used:

-

Damon from Hinesville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

9 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Spin Cycle wouldn't work

Replaced pump, by removing back panel and removing the two screws holding the pump to the bottom of the machine. The only difficult aspect was dealing with the hose clamps, these were extremely awkward to work with in a confined space. The repair would have been less than 30 min if the hose clamps weren't so difficult to put back in place.

Parts Used:

-

KEITH from BEND, OR

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

9 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wash tub would not drain/burning rubber smell

I removed the top of the washer by removing two screws on the back. I located and bypassed the lid switch to make sure that wasn't the problem. The problem still existed so I removed the two screws that hold the front panel of the washer. Using a flashlight, I located the drive belt and immediately saw that it was out of position and had pieces missing. I cut and removed the old belt, placed the new belt on the tub pulley and slowly maneuvered it onto the motor drive wheel. I then squeezed the tensioner pulley so that the belt was seated. I turned the timer dial which started the washer and it immediately began pumping the water out of the tub. Problem solved!

Parts Used:

-

Clay from Kansas City, MO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

9 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

water continually leaking into tub when not in use

Repair was harder than originally anticipated. Front had to be taken off, but trying to get all panels back in place was quite a job

Parts Used:

-

D from Baytown, TX

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

timer wouldnt clock it would just keep washing & washing

I removed the screws holding the access cover in place than the screws in the plastic ends than the screws at the bottom edge of the control panel pulled the button on the back of the timer removed the handles than one screw under the handle area to remove the timer it was easy

Parts Used:

-

Chuck from Centralia, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Timer made noise but would not move

A bit iintimidating in trying to get the knob off the timer without breaking it. finally discovered the plastic tip that went straight thru to the back, pulleed it out and walla walla the knob came off easily. Getting to the timer was a bit interesting, was not sure how far I had to tear down the washer/dryer combo front. Once I got to the part it was easy to do. I have three of these machines, two in my daughter's houses so now am dconfident i can repair if needed. Got the wrong part at first and had tosend back for the right on, got the timer for the dryer first. Expensive parts.....

Parts Used:

-

calvin from tomball, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer wouldn't spin

I used a screwdriver to remove the front of the washing machine, fit the belt around the main pulley, held in the spring loaded tension pulley, and threaded the belt aound. It works great! I really need this inexpensive repair, since my job was downsized, and I can't afford to pay anyone.

Parts Used:

-

Phillip from Huntersville, NC

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

6 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

old selector knob cracked inside could not use the dryer.

removed the old selector knob just pulled it out gently and lined up the new selector knob and gently pushed it into correct alignment. what a breeze.

reasonable prices. saved me $ on a service call, part, and labor. Thank you M

I just feel the postage is way too much for an item that weighs under 1 oz.

reasonable prices. saved me $ on a service call, part, and labor. Thank you M

I just feel the postage is way too much for an item that weighs under 1 oz.

Parts Used:

-

Marilyn from Pembroke Pines, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

6 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The front level screw legs are made of plastic and each time I move they break

-

Bobby from Asheboro, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Wrench (Adjustable)

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken belt

I took off the front panel of the washer and placed the belt on the large tub wheel and then the smaller wheel. I placed the belt over the adjustable third wheel and turned the tub in order to get the belt all the way in the grooves. Thirty minutes max to replace. Thanks, my order was 100% satisfactory

Parts Used:

-

odell from Elizabethtown, KY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

belt broke

i left my washer on its back till my belt came in and when it did all i had to do is slip the front off and go at it. it was really fast. then i put the front back on screwed in two screws and hooked up hoses and started washing everything went smooth till i was about to wash wash-n-wear and was like where is my other houseshoe and i remember my dog was bugging me while fixing my washer and dropped my house shoe and i already closed up front soi had to unhook everything and get that out, did not want it to catch on that belt i just bought and fixed lol thanks kristal cumpton

Parts Used:

-

kristal from caruthersville, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking water from machine

-

Martinus from Fort Lauderdale, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set, Wrench set

10 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer tub stopped spinning and was real noisy

I read the last three peoples experiences when I ordered the part on your on line page. I had already made all the wrong mistakes taking the machine apart, and couldn't beleive how simplified it was on your web site. I had called a local repair shop only to be advised the part would take 4 days shipping and the price of it plus shipping was twice what I paid you. Your part arrived the day after I ordered it on line, Thanks again for being there!!!!!

Parts Used:

-

Raymond from Brewster, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!