WW30430P Jenn-Air Wall Oven - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Low temperature replaced heating element

Took longer to turn off the power than replace the element ,, crazy the appliance company would charge $180.00 for a 3 minute job.

Parts Used:

-

PAUL G from FAIR OAKS, TX

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

light bulb in water ice freezer door went bad

I didn't. Don't know how to get to light bulb to change it for this specific model

Parts Used:

-

Carl from RIVERSIDE, CA

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers

7 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the hinge sring broke on one side of the oven door

Remove the screws from bottom of door to gain access to the hinge screws. Remove the bottom hinge screws and then open the door to gain access to the top hinge screws. CAUTION after removing the top screws close the door as far as possible while still griping the sides of the door. Pull up on the sides to remove the door from the stove. The springs are fully loaded if you have the door open all the way and try to lift up (like I did) the hinge will spring back and get your finger. Install the new hinge, put the door back into the oven, install all the screws and then remove the temporary rivet that comes installed in the new hinge.

Parts Used:

-

stephen from canton, MA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

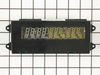

The display did not work - coud not tell oven temp - timer etc.

Removed the 3 screws from the top and 4 screws from the bottom of the touch pad. Pulled the touch pad away from the oven then disconnected the wiring harness and the strip from the old clock assembly.

Removed the 4 screws holding the assembly to the touch pad and pulled it away from the touch pad.

to assemble I just reversed the order.

Easy project.

Removed the 4 screws holding the assembly to the touch pad and pulled it away from the touch pad.

to assemble I just reversed the order.

Easy project.

Parts Used:

-

Manuel from Narrowsburg, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Digital Display Was Getting Very Dim

It took us longer to do this repair than others report, but the repair was relatively easy. As with others, our clock display was getting very dim. In fact, when we turned on the oven to bake, the clock and temperature display would both completely dim. While we were not sure that the clock assembly was the part we needed, the comments from others led us to believe that replacing the clock assembly would likely fix the problem – which it did!

To be safe, we first turned off the power to the oven. Next, using a #2 Phillips screwdriver, we removed the three screws on the top of the control panel and the four screws on the bottom of the control panel. Now, the control panel is completely loose from the oven except for the two wired connectors running between the clock assembly and the oven. The two wired connectors take a little bit of care and effort to remove since a “lip” secures them. For the four-wire connector, we were able to remove the connector by wiggling and pulling on it. For the other connector, we needed to use a small flat head screw driver to bend back the lip on the clock assembly, and then still needed to wiggle and pull on the connector to get it loose. Be careful not to pull on the wires!

Note that a connector does not terminate the ribbon cable. To remove the ribbon cable, squeeze together the two tabs on each end of the connector on the clock assembly and pull up on the connector (i.e., pull away from the board). The part of the connector that you are squeezing will rise up slightly and the ribbon cable will rise up with it. (You might want to practice with the new clock assembly to see how this works as it is easier to unhook the connector when the ribbon cable is not connected.) The ribbon cable has two holes in it that fit over two pegs on the part of the connector that rises up. The ribbon cable should simply pull out once the connector is opened up.

Use a ¼” nut driver to remove the four hex head screws that attach the clock assembly to the control panel. The clock assembly is now free from the control panel, but we still needed to pull on the clock assembly to remove it since the fit was very tight.

Assembly is simply reversing the above steps. To fit the new clock assembly onto the control panel, we needed to use a pair of pliers to first slightly bend the metal tabs on the control panel outward, as the fit (as noted) was very tight. After fitting the clock assembly into place, tighten it down with the four hex head screws. If you have not already done so, release the ribbon cable assembly on the new clock assembly by squeezing the tabs and pulling up. Fit the two holes in the ribbon cable over the two pegs on the connector, and then simply push the connector piece down until it snaps into place (making sure that the ribbon cable stays on the two pegs). Take the control panel back to the oven and reconnect the other two wire connectors. To finish up, place the control panel back on the oven, replace the seven screws, and then turn the power back on.

If your experience is like ours, you will be amazed at how bright the new display is!

To be safe, we first turned off the power to the oven. Next, using a #2 Phillips screwdriver, we removed the three screws on the top of the control panel and the four screws on the bottom of the control panel. Now, the control panel is completely loose from the oven except for the two wired connectors running between the clock assembly and the oven. The two wired connectors take a little bit of care and effort to remove since a “lip” secures them. For the four-wire connector, we were able to remove the connector by wiggling and pulling on it. For the other connector, we needed to use a small flat head screw driver to bend back the lip on the clock assembly, and then still needed to wiggle and pull on the connector to get it loose. Be careful not to pull on the wires!

Note that a connector does not terminate the ribbon cable. To remove the ribbon cable, squeeze together the two tabs on each end of the connector on the clock assembly and pull up on the connector (i.e., pull away from the board). The part of the connector that you are squeezing will rise up slightly and the ribbon cable will rise up with it. (You might want to practice with the new clock assembly to see how this works as it is easier to unhook the connector when the ribbon cable is not connected.) The ribbon cable has two holes in it that fit over two pegs on the part of the connector that rises up. The ribbon cable should simply pull out once the connector is opened up.

Use a ¼” nut driver to remove the four hex head screws that attach the clock assembly to the control panel. The clock assembly is now free from the control panel, but we still needed to pull on the clock assembly to remove it since the fit was very tight.

Assembly is simply reversing the above steps. To fit the new clock assembly onto the control panel, we needed to use a pair of pliers to first slightly bend the metal tabs on the control panel outward, as the fit (as noted) was very tight. After fitting the clock assembly into place, tighten it down with the four hex head screws. If you have not already done so, release the ribbon cable assembly on the new clock assembly by squeezing the tabs and pulling up. Fit the two holes in the ribbon cable over the two pegs on the connector, and then simply push the connector piece down until it snaps into place (making sure that the ribbon cable stays on the two pegs). Take the control panel back to the oven and reconnect the other two wire connectors. To finish up, place the control panel back on the oven, replace the seven screws, and then turn the power back on.

If your experience is like ours, you will be amazed at how bright the new display is!

Parts Used:

-

Curt from Hawthorn Woods, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven was not correctly heating to set temperature

Removed the approximatly 10 screws that hold on both the upper and lower pieces of sheet metal that cover the back of the oven. Removed the screw holding in the temp sensor. Unplugged and removed the old sensor. Plugged in and installed the new sensor (using one of the included adapter wires supplied with the sensor). Put the 2 pieces of sheet metal back on and plugged in the oven.

Parts Used:

-

Trace from Ofallon, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Elements went out in oven.

Shut off electricity to stove. Took out bolts, removed old element. Slide tabs out of connectors. Put new heating element in. Put bolts back in and turned electricity back on.

Parts Used:

-

Kathy from WHITE HALL, AR

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My daughter tipped a large dish of lasagna onto the oven door and the seal.

The door seal was an exact fit for the factory one. There are little clips that hold the seal to the door. The clips are already installed in the seal. To remove just grasp the seal at each clip and pull up. The seal comes off easily. The ends of the seal are tucked into holes at the bottom of the door so you can just pull them out. For the installation of the new seal grasp the seal at each clip and push them into the littles holes. I used a flat blade screwdriver to tuck the seal ends into the two larger holes at the door bottom. The whole process took about 10 minutes.

I wouldn't have changed the seal but the hot lasagna made the seal sort of hard after it cooled off.

I wouldn't have changed the seal but the hot lasagna made the seal sort of hard after it cooled off.

Parts Used:

-

Thomas from LK HAVASU CTY, AZ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Innner glass in oven door was crascked and had to replace

Took door off oven (easy - 2 screws) then toolk door apart to install new glass - also easy and only about 6 screws and removak of 4 nuts involved. Service from PartsSelect was excellent and deklivery was fast. Would use them again.

Irwin C. Cobane

Irwin C. Cobane

Parts Used:

-

Irwin from Lexington, KY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replacing the bulb in the freezer side

Removed the ice brucket,

Removed the light shield by releasing one screw using a nutdriver.

Replacing the bulb and reinstalled the light shield.

Your web site is one of the best and most helpfull service sites I ever used. Just wish that in the future you will ship parts overseas.

Removed the light shield by releasing one screw using a nutdriver.

Replacing the bulb and reinstalled the light shield.

Your web site is one of the best and most helpfull service sites I ever used. Just wish that in the future you will ship parts overseas.

Parts Used:

-

Yafa (and David) from Bothell, WA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

5 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The display light was not working

Removed three screws on top and 4 on bottom to open the compartment of the display clock. Four more screws were removed to take the display clock itself. Three connecting wires were easily remomed (pay attention to the thin wide wire connection, you will need to pull the tabs from both end to free the wire connection). Put the new display light in place. Connected the wire and put the screws back.

I am not a mechanic by any means and I think everyone should be able to do it easily, as long as they know how to unscrew. (dont forget to shut off the power to the oven while doing this)

Somone had suggested that they can fix the faulty part. I will send this to them for $10 only (to cover shipping and handling). They can repair and sell it. My unit is functioning except for the infamous display failure.

I am not a mechanic by any means and I think everyone should be able to do it easily, as long as they know how to unscrew. (dont forget to shut off the power to the oven while doing this)

Somone had suggested that they can fix the faulty part. I will send this to them for $10 only (to cover shipping and handling). They can repair and sell it. My unit is functioning except for the infamous display failure.

Parts Used:

-

Ravindra from Peoria, IL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

needed new oven light assembly/part #PS1864256

Removed old assembly, attached wires to new and inserted into space for same. Of course you must turn off the range circuit breaker. The part that took the most time was removing the old assembly. Once that was done, the rest took only a few minutes.

Parts Used:

-

Sara from Harwich Port, MA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

25 of 70 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

ovens wouldn't maintain temperature after preheat cycle

unplugged oven. removed 2 screws that hold the sensor in place, then removed the dozen or so screws that hold on the rear panel, unplugged sensor and fed wire through insulation. identified and installed correct harness adapter then fed new wire and connecter through insulation and connected to adapter. installed sensor retaining screws.plugged oven back in and tested function.no dice. unplugged oven once again. removed oven control panel and upon inspection of printed circuit board discovered 3 solder joints had failed. dang. resoldered failed joints and also sweetened up a few others that looked suspect. reinstalled controller, replaced all retaining hardware, and plugged in the oven. tah-dah!! works like a charm now. moral of the story is check the pc board first and save $50 for unneeded pats!!! or buy the controller from parts direct for $260ish. btw a roll of solder and soldering iron from an auto parts store cost around $10, learned to solder on you-tube $0. amazing all the home appliances yo can fix if you're not afraid to take a few screws out and poke around a bit. CHEERS!

Parts Used:

-

sherri from elk horn, IA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Inner Glass on oven door cracked

The repair for the glass on the inner door of the oven was very straight forward and easy. All I did was remove the door from the oven and then systematically took apart the door. I did not have any schematics, but if you just look at it you can figure out what you need to do. Once apart I had to use pliers to bend the metal that was holding the glass in place and then I simply installed the new one and put everything back together. The whole process took maybe 20-45 minutes from start to finish. Now I can bake a Turkey for Thanksgiving...YEAH!!

Parts Used:

-

Viraphone from Marlborough, MA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

After cleaning, F1-1 error flashed and neither oven worked

First I called a repairman and left a message. That was 3 weeks ago. So, I 'googled' the error message and determined what part I thought I needed. Ordered the part on Wednesday evening and it was there when I got home from work on Friday. I unpacked the part, got a phillips screwdriver and then watched the repair video on your website. About 20 minutes later I pushed my stove back in place and the flashing said 'set time'. Then I checked both ovens, and have since used both, and everything works!!

Parts Used:

-

Georgene from Rock City, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!