NVLR333GV0WW Hotpoint Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

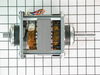

main motor bearings frozen

Having recently replaced the heating elements and main bearing on the dryer I knew how to take the thing apart, getting to the motor was easy. However, the fan side of the shaft was longer than the original so I had to bend out the metal front panel where the fan is located so it would spin without grinding against the front of the dryer. That done, the rest was easy to finish, mounting bolts on the motor tightened, one last test before putting it back together and all was well. The dryer now works better than it has for a long time.

Parts Used:

-

John from Grand Rapids, MI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench set

38 of 70 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

pivot bushing was worn out - drum not turning smoothly

First I removed the top of the unit and the front cover which allow me to remove the drum. Then I removed the worn parts, and installed the new parts.

Parts Used:

-

Scott from Pennsville, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable)

25 of 37 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Needed to change the door opening position

I removed the door and "flipped" it to open right to left. Rather than remove the existing door latch I added the purchased latch on the right side to enable opening the door right to left or left to right.

Parts Used:

-

Robyn from Laguna Niguel, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

23 of 34 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer developed a progressively noisy squeak over several months

I followed the directions that were listed on this site by other Do It Yourself individuals...by the way I'm a lady and more mechanically inclined than my husband, but he was a great help in lifting the drum up and out. (I unplugged the dryer before starting repairs)

1. I removed the two screws located at the top of the dryer inside the door.

2. Top of dryer cabinet lifted up after screws were removed.

3. Located and removed front panel retension screws and removed front panel and set aside

4. slipped belt off motor by reducing tension on idler pully

5. Removed screws inside drum that secured drum to bearing assembly

6. Husband and I lifted drum up and out of cabinet (this went very smoothly and took less than 15 minutes time.

7. Followed supplied bearing drum instructions and removed old bearing and installed new assembly.

8. Thoroughly cleaned out internal cabinet, blower, and motor areas

9. Reset the idler pully into proper position.

10. Tipped dryer on 'back' to reseat the drum With A NEW DRYER BELT (taped temporarily around the drum) into the bearing shaft (I may not be using the proper terms)

11. tipped dryer upright and while Hubby balanced the drum, the front panel was resecured to the rest of the cabinet.

12. Removed temporarily applied tape that held the drum belt in the general position, then using the rear access panel, I slipped the belt over the motor into the proper posisiton.

13. Top cabinet was reapplied and screwed into

place.

14 Plugged in and tested the dryer...NO SQUEAKS and it works beautifully and quietly!!

The job is not terribly difficult, but I am only 5 feet tall and the drum is bulky to work with and balance. Reaching into the cabinet to slip the belt onto the motor stretched my arm to the limit.

I found the cabinet reassembly and realignment of the screw holes quite annoying. But the total job proved satisfying upon completion.

1. I removed the two screws located at the top of the dryer inside the door.

2. Top of dryer cabinet lifted up after screws were removed.

3. Located and removed front panel retension screws and removed front panel and set aside

4. slipped belt off motor by reducing tension on idler pully

5. Removed screws inside drum that secured drum to bearing assembly

6. Husband and I lifted drum up and out of cabinet (this went very smoothly and took less than 15 minutes time.

7. Followed supplied bearing drum instructions and removed old bearing and installed new assembly.

8. Thoroughly cleaned out internal cabinet, blower, and motor areas

9. Reset the idler pully into proper position.

10. Tipped dryer on 'back' to reseat the drum With A NEW DRYER BELT (taped temporarily around the drum) into the bearing shaft (I may not be using the proper terms)

11. tipped dryer upright and while Hubby balanced the drum, the front panel was resecured to the rest of the cabinet.

12. Removed temporarily applied tape that held the drum belt in the general position, then using the rear access panel, I slipped the belt over the motor into the proper posisiton.

13. Top cabinet was reapplied and screwed into

place.

14 Plugged in and tested the dryer...NO SQUEAKS and it works beautifully and quietly!!

The job is not terribly difficult, but I am only 5 feet tall and the drum is bulky to work with and balance. Reaching into the cabinet to slip the belt onto the motor stretched my arm to the limit.

I found the cabinet reassembly and realignment of the screw holes quite annoying. But the total job proved satisfying upon completion.

Parts Used:

-

Richard from Hedgesville, WV

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

21 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer sqeaking loudly after it warms up

I Removed the top cover by removing the two small screws just inside the dryer door at the top. The I removed the dryer front and door assembly by removing the two small screws inside the dryer front on each side. That's it. All the parts can then be accessed and replaced easily. The entire job took 10 minutes including a good cleanout.

Parts Used:

-

John from Baytown, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

19 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

door latch was broken

Pulled out the remnants of the old latch out with the pliers and then popped the new one in...less than 2 minutes. Oh, and the part was delivered in less than 2 days. Great job, Partselect !

Parts Used:

-

Kate from MULLINS, SC

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

20 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

drive belt broke

I unplugged the machine, then unscrewed two screws that hold the top and front together, and lifted off the front door. When I pulled the drum out through the front, the belt came out broken. It was the original, so this is not a surprise. I ALWAYS take this dryer apart once a year to vacuum it out, clean all the ducts and fan, and check everything. This dryer is fifteen years old, and has survived three teenage daughters with their laundry. This time I noticed that the sliders on the front door were worn, blower wheel was loose, and rear bearing was loose,so I ordered everything. The parts came in three days. By then, you could no longer see the basement floor with piles of laundry and Friday night dates looming. I had everything replaced and working in under an hour, after which there was a conflict over who gets to use it first. Hey, I only fixed it, then I walked away. So, for 140 bucks, I have now replaced virtually every critical part, and with no rust, this thing will last as long as these guys have parts. I'm happy, my daughters are happy, and that means the wife is happy. And we all know what that means...

Parts Used:

-

Brian from Yarmouth, MA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

27 of 48 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door handle broken

-

Jennie from Louisville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

19 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wouldn't start

Removed the front panel,tiped up the top panel ,removed the drum, drive belt,motor and exaust tube assembly. cleaned and vaccumed all lint from every were. Removed motor from fan blade and houseing. Reinstalled moter and pulley that came with the moter and fan blade. reinstalled all of the rest of the parts and plugedin the wires. once all back together pluged into outlet and turned on and prasto works great.

Parts Used:

-

Pauline from South Portland, ME

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

29 of 55 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old drum bearingwore out, squeeking like a banchee

Received part in two days.

Removed inspection plate by removing two screws. .Drum bearing was right there. With screwdriver

removed "c" clip, took out what was left of old bearing.

With screwdriver aligned drum, slide new bearing into place. Job was done. Instruction with new part simple and easy to follow.

Removed inspection plate by removing two screws. .Drum bearing was right there. With screwdriver

removed "c" clip, took out what was left of old bearing.

With screwdriver aligned drum, slide new bearing into place. Job was done. Instruction with new part simple and easy to follow.

Parts Used:

-

JOE from Galion, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

17 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drive Belt Replacement needs Drum Modification

To perform this repair (please see numerous descriptions on the web for generic belt replacement) I had to rivet two loose parts to the drum in order to reinstall the drum. Specifically, the loose metal disk and hot air shroud at the rear of the drum (near the rear berrings) made it impossible to realign the parts to reinstall the three torx bolts at the rear of the drum during reassembly. These two loose parts are positioned behind the drum (when looking inside the drum) i.e. between the drum and the rear berrings.

It was necessary to align the mounting holes in the drum, disk, and air shroud outside of the dryer itself and then to rivet them in place (making sure the smooth rivet head was INSIDE the drum as to avoid providing a rough edge where the clothes could catch during tumbling). Just press the 3 torx bolts through the holes to establish correct alignment. Be sure to install the rivets ouside of the contact area between the heat shroud and mounting plate. You should see an indented pattern on the heat shroud that you can use as a guide.

It was also helpful to make a black mark on one of the drum mounting holes (inside the drum) and its mate on the berring attachment plate - to help orient you when installing the drum with the 3 torx bolts. It only aligns one way - and making the marks will save you aggravation while your head is in the drum during reassembly. Loud swearing at this point only punishes your ears because, after all, your head is in an acoustically punishing echo chamber - and the echoes make it seem as if the dryer is actually cussing YOU and your incompetence out...

I hope this helps someone else save some time in reinstalling the drum.

One additional pointer: you must remove the lower plate on the rear side of the dryer to wrap the belt around the tensioner pulley and motor drive. The belt wraps, from right to left, first around the motor pulley and then up and to the left around the tensioner pulley. Just place the belt around the motor pulley, and then pull the tensioner pulley toward you and leftward until it clears the belt, then push toward the front of the dryer - and let the tensioner contact the belt on the right side of the tensioner pulley.

And finally, the ribbed side of the belt makes contact with the drum and the motor pulley. The smooth side of the belt is in contact with the tensioner pulley. Good luck, and may the choice words I used during the process be unnecessary for you... for you... for you!

It was necessary to align the mounting holes in the drum, disk, and air shroud outside of the dryer itself and then to rivet them in place (making sure the smooth rivet head was INSIDE the drum as to avoid providing a rough edge where the clothes could catch during tumbling). Just press the 3 torx bolts through the holes to establish correct alignment. Be sure to install the rivets ouside of the contact area between the heat shroud and mounting plate. You should see an indented pattern on the heat shroud that you can use as a guide.

It was also helpful to make a black mark on one of the drum mounting holes (inside the drum) and its mate on the berring attachment plate - to help orient you when installing the drum with the 3 torx bolts. It only aligns one way - and making the marks will save you aggravation while your head is in the drum during reassembly. Loud swearing at this point only punishes your ears because, after all, your head is in an acoustically punishing echo chamber - and the echoes make it seem as if the dryer is actually cussing YOU and your incompetence out...

I hope this helps someone else save some time in reinstalling the drum.

One additional pointer: you must remove the lower plate on the rear side of the dryer to wrap the belt around the tensioner pulley and motor drive. The belt wraps, from right to left, first around the motor pulley and then up and to the left around the tensioner pulley. Just place the belt around the motor pulley, and then pull the tensioner pulley toward you and leftward until it clears the belt, then push toward the front of the dryer - and let the tensioner contact the belt on the right side of the tensioner pulley.

And finally, the ribbed side of the belt makes contact with the drum and the motor pulley. The smooth side of the belt is in contact with the tensioner pulley. Good luck, and may the choice words I used during the process be unnecessary for you... for you... for you!

Parts Used:

-

John from Windham, NH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

18 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Horrible screeching sound when dryer was running.

It took more time to figure out how to get the dryer apart than it did to fix it. Unfortunately I ordered the wrong parts the first time but Part Select was very helpful and efficient in helping me get the correct parts. I located the two screws that hold the top onto the machine inside the door frame at the top. Once the top was off, there were two screws that held the front door assembly to the dryer. The old parts (very worn and next to totally gone = none of the slides were remaining) were easy to snap out and the new parts easy to snap in to place. The Spa is happy that the dryer is quiet again and can be run when we have clients waiting. Thanks to you Part Select.

Parts Used:

-

Summit Health and Fitness from Flagstaff, AZ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

16 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door wouldn't stay shut

When I went home at Christmas, I saw that my Mom had been using a small bench to keep her dryer door shut. I wrote the make / model of the dryer down and found your website. I ordered the part, and my sister snapped it into place. My mom was so happy to have her dryer door stay shut again!

Parts Used:

-

Catherine from Windber, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

18 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken belt

Belt and pulley both broke. Ordered parts; received 2 days later. Took off front and top, positioned belt, replaced pulley and nut. Parts fit perfectly. Reinstalled covers. Ran dryer. Easy fix.

Parts Used:

-

Joseph from Girard, OH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Wrench set

20 of 32 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The plastic door handle on the dryer broke and came off.

I received the replacement part I ordered from PartSelect.com within 3 days of placing the order. I opened the plastic bag it came in. I snapped the part into the holes left vacant by aforementioned abscence of broken part.

Parts Used:

-

Jerry from Mindoro, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

18 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!