NJSR453GW3AA Hotpoint Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Drum belt broke

Removed the front Dryer panel. Left drum in place and lifted it up slightly to get access to motor drive. Slipped belt in place and put panel back on.

This was a first attempt ever at fixing an appliance and it was no big deal.

This was a first attempt ever at fixing an appliance and it was no big deal.

Parts Used:

-

Adrian from Middletown, MD

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

184 of 264 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

original duct was broken

Dear PartSelect.com,

My repair went off without a hitch.

2 screws removed to remove top.

4 screws removed from inside to remove front panel w/ door.

4 screws removed from top of control panel, loosed and popped top right off.

Flathead screwdriver to pop off old plastic panel.

Removed old wire chase (plastic, approx 3” long).

Removed built-up lint, wiped down area for new duct.

Snapped new duct on.

Dryer works like new!!

Took about 35 minutes, most of time spent cleaning up inside of dryer from lint due to broken duct.

One problem was that salesperson sold me on a new felt strip to go with new duct. That felt comes already installed on the new duct so I did not need it. Cost me a few extra dollars I did not need to spend.

Other than that, easy ordering, fast shipment, and parts are as close to original as possible.

Thanks for all your help!

My repair went off without a hitch.

2 screws removed to remove top.

4 screws removed from inside to remove front panel w/ door.

4 screws removed from top of control panel, loosed and popped top right off.

Flathead screwdriver to pop off old plastic panel.

Removed old wire chase (plastic, approx 3” long).

Removed built-up lint, wiped down area for new duct.

Snapped new duct on.

Dryer works like new!!

Took about 35 minutes, most of time spent cleaning up inside of dryer from lint due to broken duct.

One problem was that salesperson sold me on a new felt strip to go with new duct. That felt comes already installed on the new duct so I did not need it. Cost me a few extra dollars I did not need to spend.

Other than that, easy ordering, fast shipment, and parts are as close to original as possible.

Thanks for all your help!

Parts Used:

-

Chad from Gilbert, SC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

141 of 161 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Knob Post

First I unplugged the dryer, then I removed the access panel on the back of the control panel. I removed the wires from the back of the switch...Here is where I messed up. I removed the switch prior to ordering the part, the bad part is the way I removed the part. When you get the new part in you will be able to see how it will be mounted to the control panel. I had no idea, so I did what was necessary to remove it. Needless to say, I bent the hell out of the hole that the switch mounts in. In turn, the installation of the new switch did not go as easily as I would have liked. After straightening out some metal and drowning the thing in epoxy, the new switch is installed. I hooked the wires back up on the back of the switch, plug in the dryer, and dry some clothes. Standing victorious over the dryer with beer in hand, not only did I accomplish the mission but I learned my lesson... destructive removal = BAD!

Parts Used:

-

Jaren from Lemoore, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

122 of 142 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The dryer drum turned ok, but the gas heat did not start.

First I found and watched three videos on how to open the dryer and replace the igniter.

Then I opened the dryer, but I did not remove the belt as suggested in the video, and then I removed the ignitor and flame detecter as the videos had shown.

I got on-line and ordered the new parts from PartsSelect in the afternoon and had them in my hands the next morning by 9:30 am.

I installed the new parts and everything worked fine again. You must be very careful with the igniter to not touch it with hands or anything else. I practiced puting in the old parts first.

Then I opened the dryer, but I did not remove the belt as suggested in the video, and then I removed the ignitor and flame detecter as the videos had shown.

I got on-line and ordered the new parts from PartsSelect in the afternoon and had them in my hands the next morning by 9:30 am.

I installed the new parts and everything worked fine again. You must be very careful with the igniter to not touch it with hands or anything else. I practiced puting in the old parts first.

Parts Used:

-

Gary L. from Freeport, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

114 of 154 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My clothes were being "bitten", discolored with blackish smudges, and buttons eaten off clothing

First I really had to hunt for the proper way to get my dryer drum accessible for the repair. With my model it was as simple as removing two screws to take off the top panel (located by opening the dryer door), and then removing two other screws inside the front panel at the top. The front will then be able to swing to the left side (the door switch wires are on this side for this model). Simply remove the drum bearing by gently pulling it off. My slides were in such poor shape for less than 4 years old!! One of them had completely disintegrated! These slides have a small whole on one end which attaches to a small nub at the edge of a slot while the other side just slid into a slot at the other end. No need to even take out the drum!!

The hardest part of the job was to get into the dryer!

The hardest part of the job was to get into the dryer!

Parts Used:

-

Deborah from Glenburn, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

91 of 104 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not start

The end repair was very simple and took minimal effort. The time and difficulty was all in the testing. I disassembled the dryer and removed the drum and then hard wired each thermo-fuse to determine where the fault was. After test all of those I was stumped. When I opened the door the light would not come on so I assumed it was a power fault closer to the source. However after all of my testing I couldn't find anything wrong. I then removed the light bulb and realized it was burned out which led me to the door switch being the fault. I removed the switch and soldered the three wire together and the dryer started right up! All I had to do was order a new $15 part, unsolder the wires and plug them in. Would have been so much simpler if that light bulb hadn't of been burned out causing me to over think my diagnosis. This was my first major appliance repair and I did it with only the help of the parts diagram provided on the website.

Parts Used:

-

Joshua from Dallas, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

88 of 130 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer door wont stay shut

pulled out door striker anddoor latch out with pliers and just pushed in new parts. works like new in under a min.

Parts Used:

-

robert from mount joy, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

80 of 118 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

belt broken, pulley worn out

Removed 4 screws from top of control panel , remove 2 from back to lossen top of dryer. Removed rear lower access cover,6 screws on back of dryer exposing pulley and tensioner, remove broken belt and vaccuumed out a ton of lint , removed pulley and tensioner and replaced. From the front remove 4 screws and take off front of dryer, disconnecting several wires, again vaccumed out lint, lifter drum evough to replace belt. Reassembled

Parts Used:

-

Anthony from Mpls, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Socket set

68 of 102 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noisy and took too long to dry clothes

Easy repair. Removed top of dryer and removed two screws to front panel and door assembly. Old front air duct assembly was worn and broken, so it literally fell off the panel. I cleaned the front panel and door assembly of all the lint and dirt, and snapped the new parts into place. The new parts came with the gasket and felt drum seal already installed, to all that had to be done was to snap it into place. Installing the drum slides was a breeze. I simply had to slide one end in the slot, position the hole over the pin, and slide the other end in. I put everything back together, and ran a full cycle for test. Dryer works like new, and run quiet.

Parts Used:

-

Bruno from Somerdale, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

56 of 68 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Dryer Belt

I had to take most of the dryer apart because there is no rear access to the motor. It turned out to be easy to dissasembel the dryer. The only problem that I had was that I could not figure out how to route the belt around the motor and the idol pullies. I could not find anywhere that gave instructions on how to properly tension the belt. I finally figured out that the idoler pulley needs to be locked in place on the right side of the engie mount. Then the belt needs to be routed over idoler pulley and under the motor pulley. Finally release the idoler pully from the locked postion to put tension on the belt. It really turned out to be pretty easy.

Parts Used:

-

Richard from Ashton, MD

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

62 of 87 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

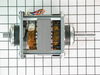

Dryer made excessively loud noise when running.

I initially opened the front of the dryer and noticed that the drum slides that the drum rides on in the front of the dryer were excessively worn. I then removed the drum and noticed that the plastic bearing that supported the drum in the rear was cracked and the washer(?) appered to be disintigrating. I ordered and replaced the drum slides and rear bearing. The dryer was still making too much noise. I ran the motor with the drum removed and realized that they motor was the remaining source of the excessive noise. I then ordered and replaced the motor with a new one and this solved the problem. Total cost was around $140. Note that when ordering a new motor, the instructions on the web site indicate that you need to order the motor pulley if your existing motor has a pressed on pulley. The new motor was a kit that came with the pulley included, and therefore the additional part was not needed, and had to be returned. The instructional videos and parts schematics on the web site were very helpful.

Parts Used:

-

Owen from Virginia Beach, VA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench (Adjustable)

58 of 76 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer cylinder wouldn't turn

Pryed off the top with a flat head screwdriver and removed the 2 screws holding the front panel to the sides. Then lifted the front panel off of the bottom brackets. Belt fit perfectly and followed the provided instructions to loop it around the motor and pulley. PartSelect got the part to me within a couple of days and the repair was a snap.

Parts Used:

-

Christopher from Miami, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench (Adjustable)

56 of 79 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The Dryer would not start

Doing some simple troubleshooting with the volt-ohm meter I determined that the door switch was failed.

The replacement door switch restored the motor circuit keeping my dryer in action.

The replacement door switch restored the motor circuit keeping my dryer in action.

Parts Used:

-

David from Curtice, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

59 of 102 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Gas dryer was not getting hot and smelled like gas inside drum

Removed lower front panel and then front including door (need to remove the top to access screws.) Replaced both the ingiter and heat detector. The tricky part was getting access to the long tunnel-like bracket that houses the igniter. Washer and Dryer are in a tight cutout space in very small laundry room.

Parts Used:

-

Todd from Santa Rosa Valley, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

51 of 85 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not start

The switch made a humming sound when I turned it so I thought that might be the problem. Using the instructions on this Web site I took the top panel of the dryer off (after unplugging it), unplugged two wires leading from the switch (needed pliers for this), and removed the switch unit by rotating it counterclockwise (when behind it).

The replacement part came in two days. The installation went a lot quicker-maybe ten minutes.

The replacement part came in two days. The installation went a lot quicker-maybe ten minutes.

Parts Used:

-

Ray from Kingwood, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

33 of 37 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!