MDE9700AYW Maytag Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Dryer did not turn when power was on.

Callled the service company to diagnose the problem. Watched him take machine apart. He found the problem. Told me the parts that I needed. Didnt know what they were. Went to partselect.com looked my model up and found parts and ordered. Followed same steps as repair guy: Two screws in back of machine then slide top off. Six screws in front to remove front door ( 4 screws on top 2 on bottom) Changed the thermostat and thermistor. Saved 320 dollars :)

Parts Used:

-

JAMIE from VALLEY STREAM, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

53 of 65 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Crack in drum

From what I understand, this is a common problem with this Samsung made Maytag Neptune dryer. The dryer was making a sound like it had a shoe in it every time it was drying. The crack was in the seam at the back of the drum behind one of the baffolds so you can't see it when you look inside. I did not see it until I took the top off the dryer, looked inside and saw light through the hole. To take the dryer apart, first unhook it from the wall, gas, electricity, and exhaust. Remove 2 skrews from the top back side and slide the top of the dryer back and remove. The plastic control panel is then removed by taking 2 skrews out from the top, pulling the top of the control panel forward and reaching in with the other hand to pop out the plastic clips of the control panel from the front face of the dryer. Unplug the control panel from the electrical panel inside the dryer. Then you can remove the front door, 2 skrews, remove the front panel, 8 skrews I think, then the front piece the the drum rides on, 1 skrew. Take the belt loose and the drum will come right out. To install just reverse. Pretty easy once I figured out how to remove the control panel. I think the reason for the drum crack is it looks as though the back pressed metal piece that the drum rides on is not perfectly round. Even the new drum makes a very light thump sound and when I watched it go around with the top off the dryer I could see the drum turn slightly oblong. Check your wheels and make sure the axles are not worn, if they are, replace them at this time. Also you might as well replace the belt too.

Parts Used:

-

Chris from Pomona, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

49 of 55 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no heat in the dryer

Remove dryer covers and locate heater assembly. Removed heater assembly and checked visually if the heater coil is opened, I verified this with an ohm meter. Heater Continuity was OK. Next step I checked the heater sensors. Thermal fuse with bracket had no ohm meter reading between two terminals[open circuit]. Order part#35001193 "thermal fuse" with bracket from "partsSelect.com." Assemble back in reverse order. Please note that the dryer heater was filled with lint and needed a good cleaning.

Parts Used:

-

Walter from Lynden, WA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

53 of 81 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Gas Flame Would Drop Out

First it was a process of alimination to find out why it was dropping out. After the problem was found it was just a matter of replacing the holding coil on the gas valve. Thank you fred kenney sr

Parts Used:

-

FRED from BRIELLE, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

47 of 64 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

A faulty computer

First remove the top of this particular dryer, to get to the necessary screws. computer is located on the left side, and 3 screws frees it up. Then disconnect the wires. Unscrew the board, and replace!! That simple!! Unfortunately for me the bad computer melted part of the wire harness. I called maytag and drove them nuts untill they paid to replace the wire harness. I learned two simple lessons. Buy the cheapest appliances you can find because everything is made like crap these days, and if you must buy the more expensive appliances, get the extended warranty because everything is made like crap these days!!!!! Thanks partselect.com for the info, and discount prices!!

Parts Used:

-

keri from lincoln park, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

37 of 45 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not heat up.

I unplugged the dryer,removed the two small screws on the front of the dryer and pulled the bottom forward. The two wires connected to the door do not have to be removed. With an electrical tester using the Ohm setting I tested the Radiant sensor and the Gas Valve coils. The two terminal coil was DOA. The dryer can be operated with the front open as long as the door wires are connected. Symptons: The igniter would heat up and not release gas. My repair was successfull due to this awesome website and the super fast shipping service. AAAA++++

Parts Used:

-

Roger from Bonners Ferry, ID

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

26 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

wet clothes in sensor dry mode(Samsung DV218)

top and the front had to be removed to get to the fan... the thermistor that sits in the exaust fan went bad... the heat would come on for a few minutes then turn off completely not getting to clothes dry.....

Parts Used:

-

Vincent from Lusby, MD

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

32 of 47 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dyer would not heat, flame would shut off within 10 seconds

I opened the panel, undid the plugs, detached the radiant sensor by undoing one screw and removed and replaced the part. Fairly simply.

Parts Used:

-

Christy from Riley, MI

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

24 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

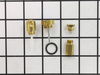

Brand new dryer...needed to convert to propane.

I followed the directions that came with the conversion kit; which I ordered from PartSelect. Your website was the only place that could help me. Our new dryer is actually a Samsung. The people at Best Buy were no help. I called the Samsung headquarters and a "real" person there told me I could order from them or use a Whirlpool kit because they are the same. You guys were faster in getting me one, so I went with you. My wife was happy. I would recommend you to others.

Parts Used:

-

Timothy from Lawson, MO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

29 of 46 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Heat Would Not Come On

After replacing all the other fuses and sensors I finally replaced the Radiant Flame Sensor and it is working perfectly.

After replacing the other parts and the heat still not coming on I read somewhere that the Radiant Flame Sensor is a normal closed circuit and when I checked with a meter it was open. I would have saved a lot of time and money if I had read that earlier.

After replacing the other parts and the heat still not coming on I read somewhere that the Radiant Flame Sensor is a normal closed circuit and when I checked with a meter it was open. I would have saved a lot of time and money if I had read that earlier.

Parts Used:

-

Lynn from Novi, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

19 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

converted gas dryer to LP

Instructions were great. Very step by step. It could not have been easier. Repair saved me a $100 service call.

Parts Used:

-

Bruce from Rogers, AR

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Wrench (Adjustable)

16 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer not heating

Had to pull the top off and the front of dryer with a few phillips screws and was able to get to the thermistor and I also replaced the heating coil because it was bad.The cause of the problem was because of a clogged up vent. It was a easy replacement.

Parts Used:

-

Michael from Parrish, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

19 of 32 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

pulley wheel locked up and belt had burned it in half.

had to take top off to get to the front cover screws.Then took the screws out of front cover, pulled it off then pulled the drum out. Man at the amount of lent in the buttom and in the heating element area. Well, after removing drum I found the problem with the pulley. When I got parts to put back together it took a little time and thinking to find out how the pulley an belt went together(belt came off when pulley finally melted in half)with holding drum up to see what's going on. The pulley is laying down,with drum in and belt around it put belt on motor shaft then pull pulley up vertical wrap belt coming down on motor side around pulley. Then put it all together.

Parts Used:

-

charlie from conroe, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

18 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lint accumulation caused wires to melt

The dryer was packed with lint and burnt lint. It was so bad I had to disassemble the entire dryer to fully vacuum it out. Thermostat and thermistor were fairly straight forward. The large wiring harness was difficult. Had to remove the top, control panel, front drum support, blower fan and housing, and finally the rear drum support. I left the old harness on the dryer, and then started around the motor as that was easy to reference in the new wiring harness. I proceeded to remove the old harness, and place the new harness in the retaining clips one clip at a time first moving towards the burner, and then going up the rear of the dryer and finally into the computer board. I had placed groups of screws in very small zip lock bags and labeled them as I took the dryer apart. This helped to remind me where all the screws went when I reassembled. Remember to NOT touch the ignitor with your fingers. Something about the oils on your fingers I was told. Reassemble in reverse order. Rear drum support, motor, gas valve (I had to remove all to clean),Turned the gas on after I reinstalled the gas valve to check for leaks, Drum and belt, attach belt, front drum support, lint trap, front panel/door, and finally the top. Then vent & plug it in and turn it on. Good luck.

Parts Used:

-

John from Los Osos, CA

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Wrench (Adjustable)

13 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Heat

I suspected a faulty igniter and disconnected the cable to the igniter and measured the resistance of the igniter and found it to be 70 ohms then I checked the voltage at the same cable towards the power source and found it to be 25 volts ac which should be 120 volts ac. Next I checked the radiant flame sensor and found it to be open (it should be a closed circuit when cold). I removed the flame sensor (with the power off) using a small box wrench and found a broken lead. Replacing the flame sensor solved the problem.

Parts Used:

-

NICHOLAS from PARMA, OH

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Wrench set

9 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!